Sine wave inverter high frequency inverter

High-frequency inverters operate at frequencies typically above 20 kHz and can produce either a modified sine wave or a pure sine wave output.Pure sine wave

Design your own Sine Wave Inverter Circuit from

Dec 19, 2024 · An op amp comparator using IC 741 or by configuring IC 555. Two sets of triangle waveform, one slow (low frequency) and the other fast (high

Pure Sine Wave Inverter: All You Need to Know

May 10, 2023 · This is where pure sine wave inverter, also known as true sine wave inverter, comes into play. They are advanced power conversion devices that produce a high-quality AC

high-frequency power inverter: high-frequency sine wave inverter

Jul 20, 2020 · The high-frequency power inverter uses a low-frequency sine wave in combination with a high-frequency DC signal so that when one is combined with the other, the two waves

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an

High-Frequency, GaN Diode-Free Motor Drive Inverter

Sep 9, 2021 · In contrast to conven-tional motor-drive-outputting, high-voltage PWM power, the GaN inverter generates pure sine wave power with-out a bulky filter. This allows motors to

High frequency verses low frequency inverters

Nov 26, 2022 · I don''t know much about low vs high frequency, but what you''ve said so far (except the quote above) more or less concurs with what I know. No - low frequency isn''t the

IBC12-3KW Pure Sine Wave Inverter (High Frequency)

Jul 1, 2025 · 1.1 Product overview IBC series pure sine wave high frequency inverter, the product integrates pure sine wave inverter, mains bypass load. Adopts full digital intelligent control

Pure Sine Wave Inverters

Aug 16, 2025 · While an inverter can produce different waveforms, a pure sine wave output is preferable because many electrical products are designed to work best with a sine wave AC

High Frequency 2500W Pure Sine Wave Inverter 3000W

Jun 3, 2025 · High frequency inverters have higher inverter conversion efficiency, lighter weight, and smaller size, making them portable and suitable for use in vehicles, camping, night

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

AN-CM-374 Sine Wave Based Inverter

Nov 27, 2024 · In order to obtain DC-AC conversion, PWM based inverters regulate the output voltage by changing the width of the pulses generated at a comparatively high frequency.

未命名 -1

Jul 7, 2025 · Overview The IPT series, a high-frequency sine wave inverter, adopts a fully digital intelligent design and voltage-current dual closed-loop control algorithm. Featured with fast

High Frequency Inverter Circuit

Nov 19, 2019 · A high frequency inverter circuit is an electronic circuit that allows for the conversion of DC electricity into AC power with a high frequency, usually around 60 Hz or more.

800VA Pure Sine Wave Inverter''s Reference Design

Jul 30, 2025 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility

4 FAQs about [Caracas high frequency sine wave inverter]

What is a high voltage dc-ac sine wave inverter?

High voltage DC-AC sine wave inverters accept wide input ranges of 450V to 800Vdc. High frequency PWM technology enables high efficiency, compact construction and low weight. ABSOPULSE has recently added the CSH 500-F6 to its line of high input voltage DC-AC sine wave inverters.

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

What is a modified square wave inverter?

The Modified Square Wave also known as the Modified Sine Wave Inverter produces square waves with some dead spots between positive and negative half-cycles at the output. The cleanest utility supply like power source is provided by Pure Sine Wave inverters.

How does a commercial 600 VA - 5 kVA inverter work?

In the traditional design of Commercial 600 VA - 5 KVA inverters, the AC mains voltage is sensed by stepping down through a bulky 50-Hz transformer by the microcontroller, which is powered up by battery through linear regulators.

Learn More

- High frequency pure sine wave inverter

- High frequency inverter sine wave

- High frequency sine wave inverter PD6KVA

- Pure sine wave inverter high power 6000 watt

- Algeria industrial frequency pure sine wave inverter

- Hanoi Industrial Frequency Pure Sine Wave Inverter

- Industrial frequency sine wave inverter multifunctional LCD

- Abuja Industrial Frequency Pure Sine Wave Inverter

- The power frequency inverter is a sine wave

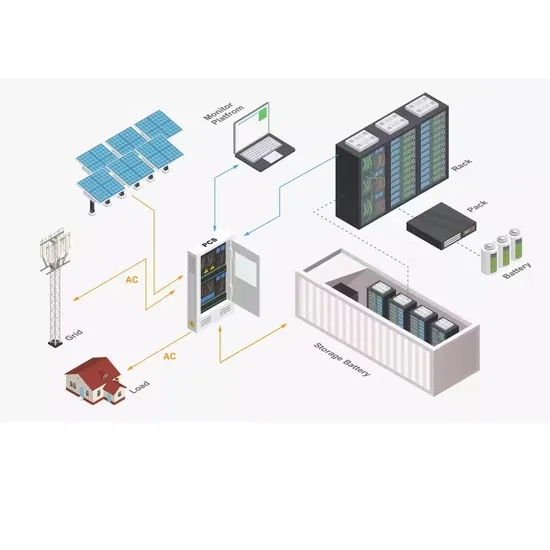

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

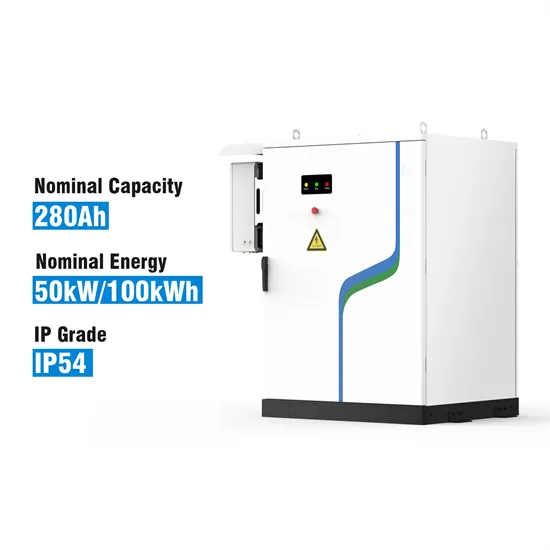

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.