A method for large-scale WEC connecting to island isolated

Dec 1, 2023 · In order to reduce the impact of the output power of WEC on isolated microgrid in remote islands, a method of splitting a high power HPGS into multiple small HPGSs is

Island Power Systems With High Levels of Inverter-Based

Aug 17, 2023 · Three grid-following (GFL) inverters could introduce some approx. 10- to 20-Hz oscillatory modes. They are well-damped before the event and move toward the imaginary

Two-stage grid-connected inverter topology with high frequency

Nov 1, 2023 · The buck–boost inverter can convert the PV module''s output voltage to a high-frequency square wave (HFSWV) and can enhance maximum power point tracking (MPPT)

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · dc–ac converter 29 High-Frequency Inverters, the HF transformer is incorporated into the integrated structure. In the subsequent sections, based on HF architectures, we

An overall introduction of inverter waveform and

Dec 20, 2023 · This article will give you a detailed introduction and comparison of inverter waveform, including the principles of generating different waveforms,

Adaptive switching frequency PWM method of SiC inverters

Dec 11, 2024 · Electromagnetic interference (EMI) noise resulting from the high-frequency harmonics in voltage source inverters (VSIs) poses a significant challenge in power electronics

Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

Analysis and suppression of high-frequency oscillation

May 1, 2020 · An impedance reconstruction control of source PWM inverters is proposed to improve the phase of output sequence impedance of the source PWM inverter at high

A High-Frequency Resonant Inverter Topology with Low

Feb 23, 2024 · to operation at Very High Frequencies and to rapid on/off control. Features of this inverter topology include low semiconductor voltage stress, small passive energy storage

Design and Development of High Frequency Inverter for

In these applications, the optimal converter design is essential for handling the high power and frequency operation. In this paper, Simulation & Hardware development of High frequency

Analysis and suppression of high-frequency oscillation

May 1, 2020 · Abstract In island power system with strong mutual interaction of power electronic devices, stability problems such as high-frequency oscillation are prone to occur. Firstly, a

Island Power Systems With High Levels of Inverter-Based

Mar 5, 2021 · As many island power systems seek to integrate high levels of renewable energy, they face new challenges on top of the existing difficulties of operating an iso

Sea Island Electric High Frequency Inverter

Do multi-inverter Islands increase island duration? In summary, for the islanding detection philosophies represented in the inverters tested, this report found evidence that performing

How to Reduce Electromagnetic Interference in Inverters

However, the process of reducing THD by choosing high switching frequency results in the generation of electromagnetic interference in the inverter. EMI From the Hard Switching of

Advanced power inverter topologies and modulation

Apr 1, 2021 · Such drive systems are usually fed by semiconductor switch-based inverters, which, unlike balanced pure sine-wave AC sources, produce large-amplitude, high-frequency

Experiences with large Grid Forming Inverters on various

Mar 26, 2020 · The grid-forming inverter (GFI) by SMA uses droops for both frequency and voltage amplitude to create the input signal for the actual voltage controller. The droops and

Isolated Grid-Forming Control of Wave Energy Converter

Apr 16, 2025 · Previous research has often used the island''s natural resources data such as solar irradiation, wind speed or significant wave height and frequency to suggest different renewable

High Frequency Inverter battery current waveform

Mar 28, 2020 · This was powering 1300W load with a high-frequency inverter that has pretty good set of electrolytic capacitors. Would expect similar current for a 48V battery inverter powering

Low vs High frequency inverters | DIY Solar Power Forum

Jun 13, 2022 · Low frequency core can absorb longer time period of peak core magnetic flux and enters core saturation less abruptly. On any transformer, saturate the core and MOSFET

Inverter design using high frequency

Oct 31, 2023 · ABSTRACT In this paper we are developing inverter which is very cheap in cost and portable we are using 50KHz frequency for DC Technique and output 250V DC, 500mA,

What are Low Frequency Toroidal Inverters?

Apr 6, 2022 · So here I heard some inverters that are "low frequency toroidal inverters". 1. What are they? Example? 2. What is their advantage vs regular

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

High Frequency Inverter Circuit

Nov 19, 2019 · A high frequency inverter circuit is an electronic circuit that allows for the conversion of DC electricity into AC power with a high frequency, usually around 60 Hz or more.

Pure Sine Wave Inverters

Aug 16, 2025 · While an inverter can produce different waveforms, a pure sine wave output is preferable because many electrical products are designed to work best with a sine wave AC

6 FAQs about [Island electromagnetic wave high frequency inverter]

Can a PWM inverter suppress high-frequency oscillation of the island power system?

Based on the impedance model, the oscillation mechanism of the island power system is analyzed. On the basis of traditional dual-loop control, an impedance reconstruction control of the source PWM inverter is proposed, which can effectively suppress the high-frequency oscillation of the island power system.

What are the features of a high frequency inverter?

to operation at very high frequencies and to rapid on/off control. Features of this inverter topology include low semiconductor voltage stress, small passive energy stora e requirements, fast dynamic response, and good design flexibility. The structure and operation of the pr posed topology are described, and a design procedure is introduced. Exp

What happens after adding impedance reconstruction control in a PWM inverter?

After adding impedance reconstruction control, the output voltages and currents of the source PWM inverter loaded with pure resistive load remain stable under different output power; when the load is a PWM rectifier, the high-frequency oscillation of the island power system is effectively suppressed.

Why is the island power system dangerous?

However, the island power system does not have the support of the utility grid, and the island power system is high-penetration of power electronics, which is prone to the “source-load interaction” oscillation problem , seriously affecting the safe and stable operation of the island power system. Fig. 1.

Are island power systems forging a path for larger interconnected power systems?

And because island power systems are often among the first to reach these very high instantaneous levels of wind and PV generation, we note that they are forging a path for larger interconnected power systems to follow. Need Help?

What is a 30 MHz 2 inverter?

of a 30 MHz Φ2 inverter designed to deliver up to 520 W to a33.3Ω re istive load and over an input voltage range between 160 V to 200 V. The semiconductor switch selected for this design is a 500 V vertical MOSFET (ARF521) which has an Rds,ON= 1Ω and an COSS=55.42 pF at Vds V. Details = 160 on the modelling of the semiconductor

Learn More

- Belgian electromagnetic wave high frequency inverter

- High frequency sine wave inverter PD6KVA

- High frequency pure sine wave inverter

- Caracas high frequency sine wave inverter

- Inverter high voltage main frequency or low voltage mixed frequency

- Efficiency of high frequency inverter

- Eritrea High Frequency Inverter

- Assembly of high power industrial frequency inverter

- High power square wave inverter

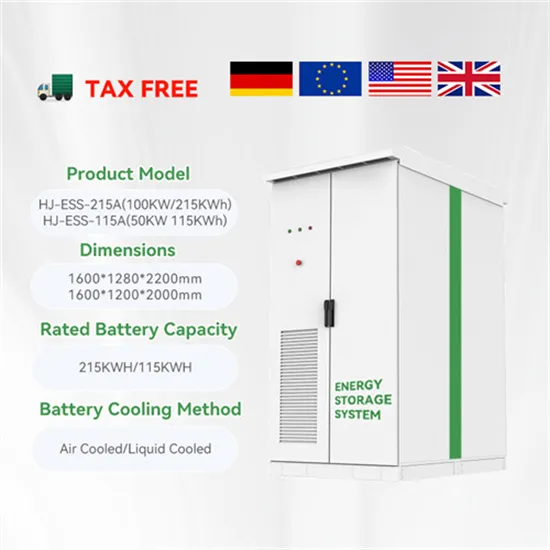

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.