Advanced power inverter topologies and modulation techniques for

Apr 1, 2021 · PWM-controlled inverters produce substantial common-mode voltage (CMV). CMV causes motor/drive malfunctions and, eventually, system breakdowns. CMV can greatly be

PWM Techniques for Two-Level Voltage Source Inverters: A

Apr 21, 2025 · This paper presents a comprehensive overview of PWM techniques for two-level voltage source inverters and provides a comparative analysis of commonly employed PWM

"Modulation in Voltage Source Inverters: an Algebraic

Sep 10, 2024 · In the case of an odd number of phases n, it is possible to to achieve some gain in the output voltage amplitude using space vector modulation or injecting the zero-sequence AC

Studying the effect of over-modulation on the output voltage

Sep 1, 2013 · For better efficiency, single-stage inverters are recommended. In this paper, the performance of single-stage three-phase grid-connected boost inverter is investigated when its

A review on modulation techniques of Quasi-Z-source inverter

Dec 1, 2024 · In the literature, various modulation techniques have been developed that help to boost the voltage of the PV modules by implementing shoot-through (ST) in which the upper

SVM Strategies for Multiphase Voltage Source Inverters

Sep 19, 2017 · The maximum modulation index is defined here as the ratio between output phase-to-neutral voltage (peak) of the fundamental component and the DC-link voltage except for

A comprehensive review of multi-level inverters, modulation,

Jan 3, 2025 · The amplitude modulation index (ma) in this method allows for control over the inverter''s fundamental-frequency component of output voltage. It is calculated using the

Unipolar and Bipolar PWM Inverter

Dec 29, 2014 · This pulse width modulation inverter is characterized by simple circuitry and rugged control scheme that is SPWM technique to obtain inverter output voltage control and to

Lecture 23: Three-Phase Inverters

Feb 24, 2025 · A half-bridge inverter requires only two devices and can synthesize a positive and a negative output {+ 1 VDC, − 1 VDC } but no zero state, while a full-bridge inverter can

Comprehensive Analysis of Modulation Techniques for Two-Level Inverter

Jun 1, 2019 · Three (3)-phase voltage source inverters are extensively used for different applications requiring high power. A three (3)-phase voltage source inverter circuit changes

Study and implementation of space vector pulse width

2P3L type VSI voltage inverter implemented by SVPWM vector space modulation method has a voltage source reverse circuit structure consisting of 6 large power switches as shown in figure

A comprehensive review of multi-level inverters,

Jan 3, 2025 · roduce a sinusoidal output voltage by utilizing various voltage levels, often derived from capacitor voltages. The MLI can synthesize the higher output voltage even by employing

Neutral-point voltage control method of multi-phase three

Dec 4, 2024 · The medium-voltage multi-phase open-winding motor and the multi-phase three-level neutral-point clamped (3L-NPC) H-bridge inverter are the preferred solutions for large

Comparison of three-phase inverter modulation

Jun 22, 2024 · This paper presents a comprehensive comparison of two primary modulation techniques employed in three-phase inverters: Sinusoidal Pulse Width Modulation (SPWM)

Comparative analysis of different types of pulse width modulation

Jan 1, 2025 · The proposed inverter generates 15 level output voltage with suitable switching pulse generation using multicarrier sinusoidal pulse width modulation (MSPWM) and different

Simulation And Comparison Of Space Vector Pulse

Mar 8, 2022 · Space-vector (SV) pulse width modulation (PWM) technique has become a popular PWM technique for three-phase voltage-source inverters (VSI) in applications such as control

Overview of Multilevel Inverter Topologies and Modulation

Feb 22, 2022 · This paper reviews classic multilevel inverter topologies and new topologies, also summarizes the applications of multilevel inverter in various fields. In addition, this paper

PWM Techniques for Two-Level Voltage Source Inverters: A

Apr 21, 2025 · Pulse width modulation (PWM) techniques are widely used to control the switching of semiconductors in power converters. This paper presents a comprehensive overview of

Comparative Study of Modulation Techniques for Two

Aug 14, 2025 · voltage-source-converter modulation techniques have been intensively researched. In principle, all modulation methods aim to lower harmonic distortion in the output

The Generalized Discontinuous PWM Scheme for Three

Oct 16, 2014 · Olorunfemi Ojo, Senior Member, IEEE Abstract—This paper presents analytical techniques for the determination of the expressions for the modulation signals used in the

Commonly Used Types of Modulation Schemes in Inverters

Modulation involves adjusting the on and off duration of inverter switches under constant input DC voltage to achieve controlled inverter output voltage. The most popular modulation technique

Modulation and control of multilevel inverter for

Jan 1, 2017 · A multilevel inverter (MLI) with staircase waveform having maximum number of voltage levels at any desired voltage (or frequency) of a variable

SVM Strategies for Multiphase Voltage Source Inverters

Sep 19, 2017 · Abstract This paper compares Space Vector Modulation (SVM) strategies for multiphase inverters. Symmetric, discontinuous, and group-based SVM and Sinusoidal Pulse

Unipolar PWM Single Phase Inverter with RL Load

Oct 27, 2024 · By varying the pulse width, the amplitude of the output voltage can be precisely controlled, allowing for flexible voltage regulation in different load conditions. Disadvantages of

6 FAQs about [Inverter voltage modulation]

What is inverter modulation?

Modulation involves adjusting the on and off duration of inverter switches under constant input DC voltage to achieve controlled inverter output voltage. The most popular modulation technique used in inverters is pulse width modulation (PWM). Space vector modulation is often used in inverters due to its ease of implementation.

Which modulation techniques are used in three-phase inverters?

This paper presents a comprehensive comparison of two primary modulation techniques employed in three-phase inverters: Sinusoidal Pulse Width Modulation (SPWM) control and Space Vector Pulse Width Modulation (SVPWM) control.

Which PWM techniques are used in two-level voltage source inverters?

This paper presents a comprehensive overview of PWM techniques for two-level voltage source inverters and provides a comparative analysis of commonly employed PWM techniques, including sinusoidal PWM, zero-sequence injection PWM, third-harmonic injection PWM, space vector modulation, and optimized pulse pattern with selective harmonic mitigation.

How to control inverter output voltage?

The inverter output voltage can be controlled in various ways. Modulation is an internal method of controlling an inverter to generate the desired voltage waveform. Compared to other methods of inverter control, modulation requires no additional components.

What is pulse width & space vector modulation?

The pulse width is the sinusoidal function of the angular position of the pulse in a cycle. Space vector modulation - The space vector modulation scheme is commonly used in inverters due to its ease of implementation. It is frequently employed in multilevel inverters.

How to control an inverter?

The aforementioned methods of inverter control require additional components to generate output voltage or the desired magnitude, phase, and frequency. Modulation involves adjusting the on and off duration of inverter switches under constant input DC voltage to achieve controlled inverter output voltage.

Learn More

- Inverter voltage modulation

- 180 degree voltage inverter replacement

- Huawei inverter voltage

- What is the maximum voltage of a 48v inverter

- High frequency inverter capacitor and resistor voltage reduction

- Morocco high voltage energy storage inverter manufacturer

- What is the inverter output voltage

- Inverter input voltage suddenly decreases

- How much does a 1000w voltage inverter cost

Industrial & Commercial Energy Storage Market Growth

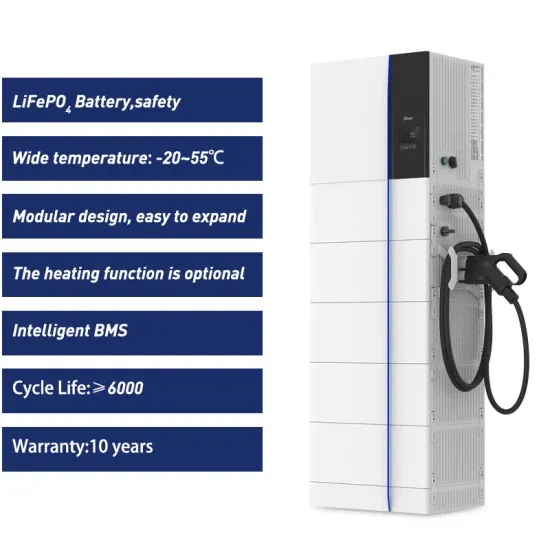

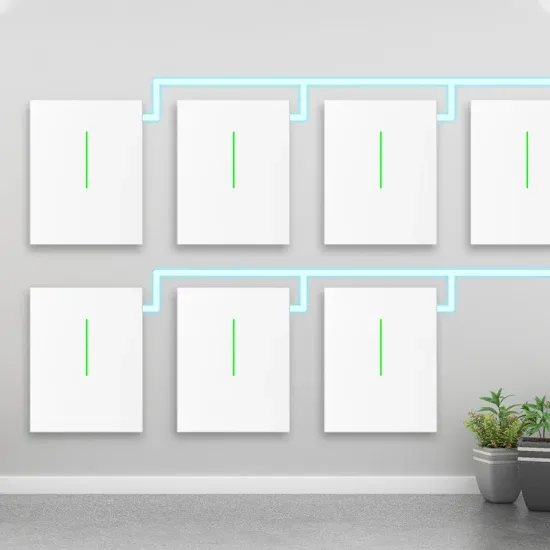

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

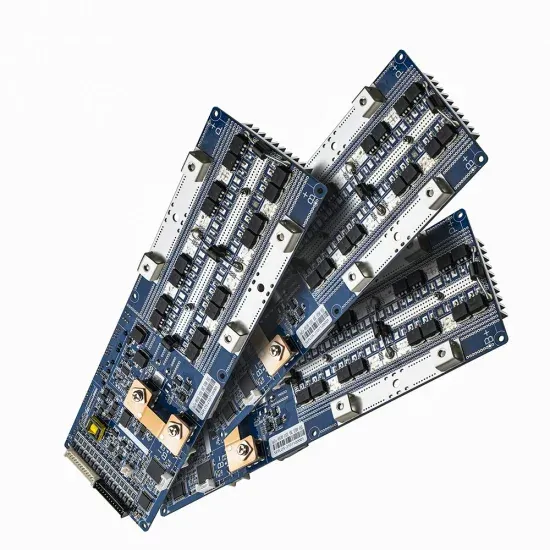

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.