Gallium Nitride (GaN) based High-Power Multilevel H

May 21, 2024 · A GaN-based inverter prototype was employed to deliver a 85-kHz power to the wireless charging pads of the wireless power transfer system. Experimental results at two

How to Safely Connect a Battery to an Inverter: A

Apr 13, 2025 · High-power applications require the use of large gauge cables to prevent overheating and voltage drops and to ensure safety when connecting

Grid Forming Inverters for Electric Vehicle Charging Stations

Jun 24, 2025 · Grid Forming Inverters for Electric Vehicle Charging Stations to Enhance Distribution Grid Resilience Published in: IEEE Access ( Volume: 13 ) Article #: Page (s):

Power Source / Sink Inverters for high efficient EV

Mar 24, 2021 · 1 Abstract The race for power conversion efficiency over 99% continues. New innovative topologies are competing with the standard half-bridge topology using SiC and GaN

Infineon high voltage Inverter Application Presentation

May 25, 2025 · For EV traction inverter, more efficiency and right performance are key. While IGBT is ideal for cost-optimized drive-train, SiC demonstrates higher efficiency under WLTP

Battery Drain Rate with Power Inverter Explained

Aug 19, 2025 · Unlock the secrets of power inverter battery usage and learn how fast your power inverter will drain battery life to manage energy consumption

Gallium Nitride (GaN) based High-Power Multilevel H-Bridge Inverter

May 18, 2024 · This paper presents a design and implementation of a high-power Gallium Nitride (GaN)-based multilevel Hbridge inverter to excite wireless charging coils for the wireless

what size inverter do ev charging stations need | AMPPAL

6 days ago · Remember that putting in a high-power inverter for EV charging usually means getting professionals involved and following local rules for permits and safety. Understanding

Energy management of a multi-battery system for renewable-based high

Nov 1, 2022 · Highlights • Battery storage can facilitate high power EV charging with limited impact on distribution grids. • Investigation of hybrid charging infrastructure with reconfigurable

Gallium Nitride (GaN) based High-Power Multilevel H

May 21, 2024 · Abstract—This paper presents a design and implementation of a high-power Gallium Nitride (GaN)-based multilevel H-bridge inverter to excite wireless charging coils for

Efficient Boost Integrated High Frequency Inverter based

Oct 9, 2024 · Conventional IC-based transportation is replaced by modern electric vehicle EVs to limit Greenhouse gas emissions (GHG). However, EV charging is completely depe

Understanding How an Inverter Charger Charges

Jul 4, 2023 · A. Bulk Charging During the initial phase of battery charging, the inverter charger operates in the bulk charging mode. It supplies a high current

12 Volt Inverters With Battery Charger

By using direct current from a battery during power outages and recharging those same batteries seamlessly when utility alternating current is available an inverter charger will give you a worry

High-Power Electric Vehicle Charging Hub Integration

Apr 2, 2024 · This report details the design and development of a high-power, interoperable charging experimental testbed under the High-Power Electric Vehicle Charging Hub

high-power inverter based hybrid switch SiC+IGBT

Mar 19, 2024 · Hybrid switch configuration considfred is 1:4 ratio (1 SiC + 3 IGBTs) Efficiency gain of full SiC Inverter and hybrid switch inverters vs IGBT inverter is from low load to medium

An Efficient Wireless Power Transfer System for EV

Apr 19, 2025 · In recent years, Wireless Power Transfer (WPT) systems have been utilized as EV battery chargers. Designing effective power electronic converters enables the WPT system to

Gallium Nitride (GaN) based High-Power Multilevel H-Bridge Inverter

Jun 21, 2024 · This paper presents a design and implementation of a high-power Gallium Nitride (GaN)-based multilevel H-bridge inverter to excite wireless charging coils for the wireless

Charging Battery While Connected To Inverter

Mar 3, 2023 · Can I charge a battery while it''s connected to an inverter? in short, the answer is Yes, you can charge a battery while using an inverter. but make

6 FAQs about [High power inverter charging]

What is a topcharge inverter?

The inverter was tested as part of the TOPChargE project . The inverter efficiency is modelled with two loss components. Constant losses of 100 W account for consumption of inverter auxiliary systems, such as controllers, measuring electronics, and drive circuits.

Can battery storage facilitate high power EV charging?

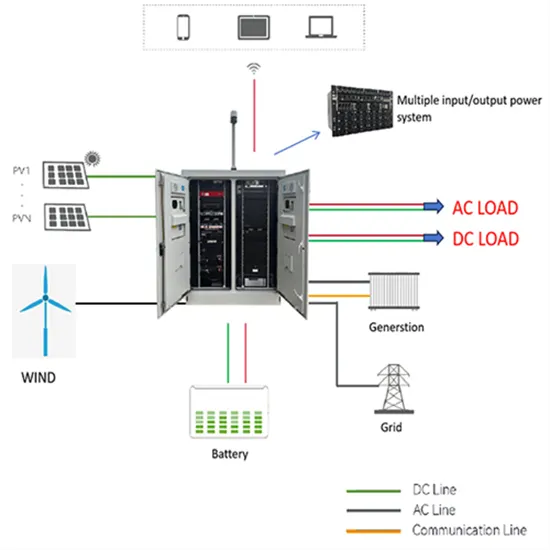

Battery storage can facilitate high power EV charging with limited impact on distribution grids. Investigation of hybrid charging infrastructure with reconfigurable battery and PV system. Energy management system allocates battery strings to system components via busbar matrix.

What EV charging solutions does ABB offer?

ABB offers a total ev charging solution from compact, high quality AC wall boxes, reliable DC fast charging stations with robust connectivity, to innovative on-demand electric bus charging systems, we deploy infrastructure that meet the needs of the next generation of smarter mobility.

Is a grid-independent solar-based wireless EV charging system possible?

Here this article proposes a grid-independent solar-based Wireless EV charging system utilizing an integrated boost MPPT controller and T-type inverter. The proposed WPT-based EV charging system integrates the MPPT of solar PV with a high-frequency T-type inverter for wireless charging.

What is MPPT integrated T-type inverter for wireless EV charging system?

The designed proposed MPPT integrated T-type inverter for Wireless EV charging system is simulated in MATLAB/Simulink model. A hardware prototype model of the proposed WPT-based EV charging is developed for 3.7kW for real-time validation of the proposed solar MPPT Boost integrated EV charging.

What is the difference between inverter and PV?

The inverter discharges String 3 at around 20 kW, while the PV is charging String 1 at power values around 45 kW. Time ④ serves as an example of an EV connecting at Charger 2, because Charger 1 is already taken by another EV. Hence, at that time, String 3 is not available.

Learn More

- 5kva high frequency power inverter

- High power industrial frequency inverter

- High quality off grid solar power inverter Price

- The difference between inverter and high frequency power generation

- Black Mountain Power Inverter 60v to 220v High Power

- Top 10 high power inverter brands

- High power inverter and ordinary

- Volt inverter high power

- Amorphous inverter to high power

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.