What You Need To Know About a High Volt Inverter

Aug 16, 2025 · A high-voltage inverter is designed to convert DC power into AC at a higher voltage than a standard inverter. It can accept inputs from high-voltage power sources and

Inverter, Solar Inverter, Home Power Inverter | inverter

High quality and reasonable price 300 watt pure sine wave inverter for sale, 12 volt DC, AC output can select 100V, 110V, 120V, 220V, 230V and 240V, output frequency 50Hz or 60Hz. Power

12v Inverter, 12v DC to 110v/220v AC Power Inverter | inverter

12V power inverter with continuous power 2000 watt, 4000 watt peak power, and max efficiency 90%. The 2000w modified sine wave inverter can convert 12 Volt DC to 110/120 Volt or

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · Many fields use this inverter, such as motor control, UPS, and solar inverter systems. The main function of the inverter is to convert the DC power to AC power by using

Infineon high voltage Inverter Application Presentation

May 25, 2025 · For EV traction inverter, more efficiency and right performance are key. While IGBT is ideal for cost-optimized drive-train, SiC demonstrates higher efficiency under WLTP

High Voltage Inverters: Understanding Its Benefits and

Jan 23, 2025 · A high-voltage inverter is designed to convert low-voltage DC power to high-voltage AC power efficiently. These inverters are commonly used in applications that require

High Voltage Solutions in HEV/EV Part II:

Aug 19, 2025 · What will I get out of this session? Purpose: To provide an overview of complete high voltage power solutions in DC-DC Conversions and Tractions Inverters Introduction

How voltage impacts EV efficiency, performance, and cost

1 day ago · Modern inverter technology enables efficient voltage conversion, reduced losses, and scalable power delivery for electric mobility applications. This article explores how voltage

The Technology Behind High Input Voltage Inverters

Feb 22, 2024 · Improved Power Quality: High input voltage inverters ensure stable and clean AC power output, eliminating voltage fluctuations or harmonic distortions. This ensures the

High-voltage inverter | EV traction inverter | Eaton

Feb 1, 2024 · Explore Eaton''s high-voltage inverter converts direct current (DC) from the batteries or generator to alternating current (AC) to power the traction

Power Inverters: What Are They & How Do They

Dec 17, 2019 · Key learnings: Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for

High Voltage Inverter: Unlocking the Potential of High-Power

Aug 17, 2025 · High voltage inverter is an important device in the sustainability of renewable energy systems on a medium to large scale. Due to its ability to handle high voltages, its use

Demystifying high-voltage power electronics for solar

Apr 1, 2023 · Demystifying high-voltage power electronics for solar inverters Nagarajan Sridhar Strategic Marketing Manager, SiC and Smart Isolated Drivers Texas Instruments The

High Voltage Inverters & Batteries | Solar Warehouse SA

A high voltage inverter typically has an input voltage range of more than 100V and an output voltage range of 220V to 480V. A high voltage inverter can handle higher power output and

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · WP4000 frequency conversion power analyzer can realize the input, output and efficiency test of high voltage frequency converter with voltage of 10kV and current of 7000A

Infineon high voltage Inverter Application Presentation

May 25, 2025 · Advantage of Infineon Discrete IGBT (TO247-PLUS) Infineon''s industry-leading discrete IGBTs are compatible with Empower''s latest generation inverter in terms of

24v Inverter, 24v DC to 120v/240v AC Power Inverter | inverter

Favorable price 24V 2000W power inverter for sale, modified sine wave power and peak power 4000W, output voltage 110V/120V and 220V/230V/240V AC for options, strong durability, and

6 FAQs about [Volt inverter high power]

What is a high voltage inverter?

To power motors or other devices, high-voltage inverters convert direct current (DC) from batteries or generators to alternating current (AC). With nominal DC voltage up to 1 kV and maximum power up to 300 kW each, our inverters support a variety of applications including traction drives, grid connections, and island grids.

How does a high-voltage full bridge inverter work?

A high-voltage full bridge inverter works by converting the DC voltage V1 to a high-frequency square wave AC voltage. This AC voltage is then supplied to a 20kHz frequency high-voltage transformer T1, which, after the boost rectifier, provides power to the load. The inverter high-voltage full bridge drives the routing components and the IGBT power modules.

What is a 400V inverter?

The 400V inverter is the brain at the heart of the electric powertrain, it controls the electric motor. It converts Direct Current (DC) from the battery to Alternative Current (AC) to power the electric motor.

What is the main circuit of an inverter?

The main circuit of an inverter includes an inverter DC power supply, IGBT bridge inverter, protection circuits, high frequency high voltage transformers, and high frequency high voltage silicon stack (Rectifier).

What is the power range of a Samsung inverter?

The power range includes 75K, 80K, 100K, and 125K. The inverter series, which boasts a maximum charge/discharge current of 100A+100A across two independently controlled battery ports, has 10 integrated MPPTs with a string current capacity of up to 20A – ensuring unmatched power delivery.

How to convert DC voltage to AC voltage?

Inverter's main circuit converts DC voltage V1 to a high frequency square wave AC voltage. This high-voltage AC voltage is then supplied to a 20kHz frequency transformer T1. The boost rectifier provides power to the load. By controlling the duty cycle of PWM1 and PWM2, a pulse width adjustable rectangular wave AC voltage is obtained. Inverter main circuit DC voltage V1 is converted to a high frequency square wave AC voltage for further processing.

Learn More

- The difference between inverter and high frequency power generation

- High power inverter charging

- High power inverter and ordinary

- High quality off grid solar power inverter Price

- Amorphous inverter to high power

- High power square wave inverter

- KW-level high power inverter

- High quality wholesale 1500 power inverter for sale

- 3000w high power inverter

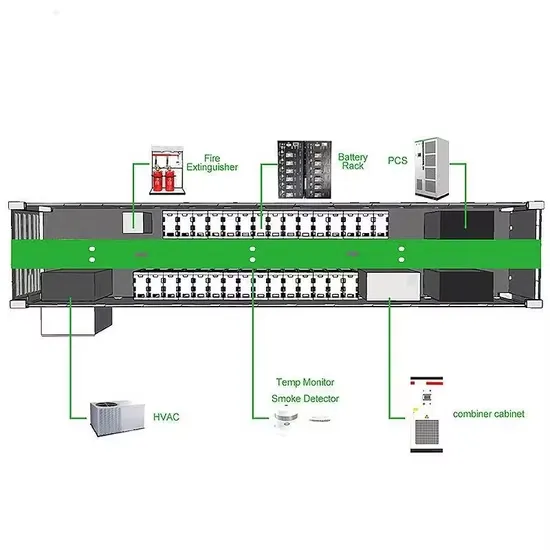

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.