The Role and Application of Nanocrystalline and High Flux

Introduction: Powering the Future with Advanced Magnetic Cores Inverters are at the heart of renewable energy systems, electric vehicles, and high-efficiency industrial power supplies.

Optimal design of high frequency magnetic links for power

Oct 1, 2023 · The high-frequency standard magnetic links were recently considered viable candidates for construction of the medium-voltage power converters, rather than link with the

Amorphous Silicon Thin-Film Transistors for Digital Circuits

Mar 4, 2023 · For any integrated circuit technology used in digital design, digital circuits can be modeled as an inverter. Once the operation and characteristics of the inverter circuit are

Photovoltaic inverter amorphous reactor

Amorphous core are with high saturate induction, rectangular form, with excellent anti-bias current ability, low core loss excellent stability.Mainly use for PV inverter, high frequency large power

Design Considerations for Implementing Amorphous Cores in Inverter

Mar 10, 2025 · Before discussing the design considerations, it is crucial to have a clear understanding of amorphous cores and their properties. Amorphous cores are made from a

Low voltage, high gain inverters based on amorphous zinc

Jun 24, 2020 · Metal insulator semiconductor field-effect transistor (MISFET) based inverters also show low peak gain magnitudes (pgm) in the order of 5. To achieve low-voltage high-gain

Performance enhancement of solution-processed amorphous

Jul 1, 2023 · The high-k gate dielectric can provide a thicker physical thickness, suppress direct electron attempt penetration, and maintain optimal gate capacitance, thus reducing gate

Amorphous Cores: Enabling High-Efficiency Power

Mar 10, 2025 · Amorphous cores offer a wide frequency range for power conversion. Unlike traditional magnetic materials, amorphous cores can operate at high frequencies, making them

HIGH-FREQUENCY MAGAMP POWER INVERTER

Oct 8, 2018 · The paper suggests a new method of the design of the power inverter based on high-frequency magnetic amplifiers. The proposed circuitry allows obtaining the higher quality

Design and performance analysis of the three-level isolated

Jul 13, 2017 · In this study, an isolated three-level DC-DC converter is proposed for high power and high conversion ratio applications such as fuel cells. The proposed system consists of a

High-performance full-swing a-HfInZnO inverter and

We report the fabrication and characterization of high-performance, full-swing inverter and logic circuits based on amorphous hafnium-indium-zinc-oxide (a-HIZO) thin film transistors (TFTs)

Amorphous Toroidal Cores for Renewable Energy Inverters

Jul 26, 2024 · This makes them ideal for use in high-frequency power inverters, allowing for a more efficient conversion process with reduced energy losses. The ability of amorphous

Iron Loss Properties of Amorphous Ring under High

May 19, 2022 · In recent years, amorphous materials have been used for inductor and transformer cores to improve the efficiency of high power-density converters utilizing wide

Application of a new orthogonal-flux-type amorphous core to high

Aug 6, 2002 · The parametric oscillator, a self-oscillating invertor using a Royer circuit, shows an efficiency of 47% at 18.5 kHz and offers overcurrent protection. As a separately controlled

Amorphous Photovoltaic Inverter Market Report: Trends,

Jun 30, 2025 · The future of the global amorphous photovoltaic inverter market looks promising with opportunities in the power grid and power station markets. The global amorphous

The Role and Application of Nanocrystalline and High Flux

They feature high initial permeability (5,000–31,000 µr at 100kHz), ultra-low core losses in the 10–100kHz range, and a high saturation flux density (1.23–1.32 T), which is 2–3× higher than

The Development of New Amorphous Cores for High

The core losses of amorphous material with domain wall movement magnetization are high and are dominated by anomalous losses. This is corrected by applying magnetic annealing (up to

Core losses of an inverter-fed permanent magnet

Apr 8, 2020 · In this paper, an interior permanent magnet synchronous motor (IPMSM) with a stator core made of amorphous magnetic material (AMM) is presented. The IPMSM is driven

Low voltage, high gain inverters based on amorphous zinc

Jun 24, 2020 · Amorphous oxide semiconductors (AOSs) are a promising class of materials that exhibit a high electron mobility of 10 cm 2 V −1 s −1 and higher while they can be fabricated in

Amorphous Toroidal Cores for Renewable Energy Inverters

This makes them ideal for use in high-frequency power inverters, allowing for a more efficient conversion process with reduced energy losses. The ability of amorphous toroidal cores to

Amorphous Core Materials for High-Efficiency Solar Inverters

May 20, 2025 · The utilization of amorphous core materials in high-efficiency solar inverters offers numerous benefits in terms of enhanced magnetic performance, reduced total harmonic

4000w 5000w 6000w 8000w Amorphous Pure Sine Wave Inverter

Aug 9, 2023 · 【PURE SINE WAVE INVERTER】High power amorphous inverter, which can convert DC 12V/24V/48V/60V to AC 110V/220V power converter, stable and efficient. The

Iron Loss Properties of Amorphous Ring under High

May 19, 2022 · In recent years, amorphous materials have been used for inductor and transformer cores to improve the efficiency of high power-density converters utilizing wide-bandgap

5 FAQs about [Amorphous inverter to high power]

How to correct amorphous material with domain wall movement magnetization?

The core losses of amorphous material with domain wall movement magnetization are high and are dominated by anomalous losses. This is corrected by applying magnetic annealing (up to 5T magnetic field) in a transverse direction to the easy axis at diferent temperatures starting from 500 °C.

Which amorphous materials are used in power inductor applications?

Nickel–iron alloy (NiFe) cores are commonly used in power inductor applications as they ofer good coercivity compared to ferrites and have higher flux densities as well. The chart in Figure 2 shows that amorphous materials have a good mixture of coercivity and saturation flux density.

Why do magnetic materials have a higher anisotropic energy?

All magnetic materials have these qualities although some have higher anisotropic energies, which is the energy required to rotate the magnetic domains to a saturated state where the applied field has no efect, than others and a few materials enable better performance at diferent switching frequencies compared to others.

Do amorphous materials have a good mixture of coercivity and saturation flux density?

The chart in Figure 2 shows that amorphous materials have a good mixture of coercivity and saturation flux density. The composition of amorphous materials consists of trace elements such as Cobalt and Iron together with mixtures of Silicon and other elements such as Niobium.

What is the composition of amorphous materials?

The composition of amorphous materials consists of trace elements such as Cobalt and Iron together with mixtures of Silicon and other elements such as Niobium. One of the objectives of this research was to prepare and test amorphous material which did not depend on traditional elements and resulted in reducing the material cost by 30 %.

Learn More

- Grid-connected inverter high power

- New generation of intelligent industrial frequency high power inverter

- High power square wave inverter

- What is the maximum power of a 12v high power inverter

- Inverter power frequency high frequency

- Micronesia le series high power inverter manufacturer

- 12V24V Universal High Power Inverter

- Top 10 high power inverter brands

- High power inverter quotation

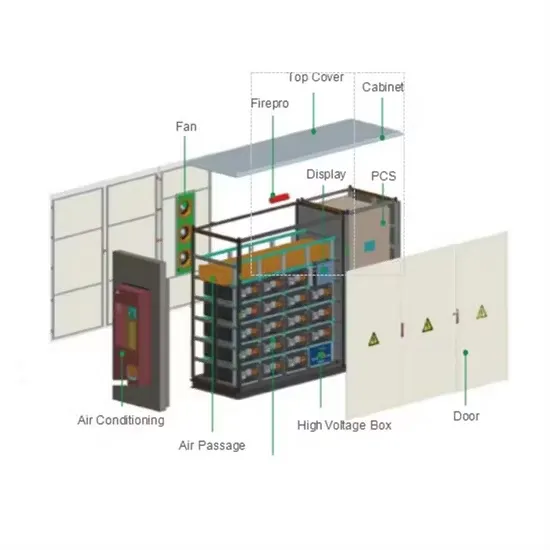

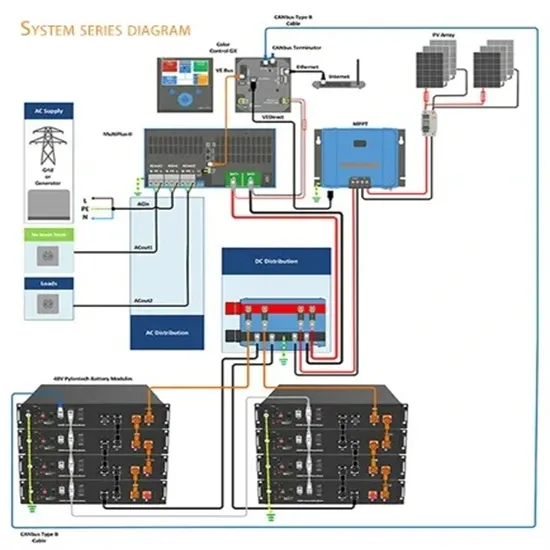

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.