High Frequency Inverter Circuit

Nov 19, 2019 · A high frequency inverter circuit is an electronic circuit that allows for the conversion of DC electricity into AC power with a high frequency, usually around 60 Hz or more.

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · Low-Frequency Inverter: An Overview A low-frequency inverter operates at a lower switching frequency, typically below 60 Hz. It is designed for applications requiring high power

ALPHA 6600 high performance frequency inverter By

ALPHA***0 inverter is high performance inverter combined with ALPHA***0''s hardware according to the market demand. It can drag max. 4 units motors (2 units for circular running) without

HG6600多功能过程信号校测仪

Aug 17, 2025 · HG6600 多功能过程信号校测仪(手持式) 的主要特点有:手持式,大屏幕,汉字显示;提供24V回路电源给变送器供电,可以同时回测电流;

High Frequency Inverter Circuit

Nov 19, 2019 · High Frequency Inverter CircuitIn recent years, there has been an uptick in interest in high frequency inverter circuits. From purifying water to helping regulate the flow of

A High-Frequency Inverter for Variable-Load Operation

Jan 18, 2019 · This paper presents a new inverter architecture suitable for driving widely varying load impedances at high frequency (HF, 3-30 MHz) and above. We present the underlying

A High Performance High Frequency Inverter Architecture

Oct 14, 2021 · In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

High Frequency Inverter at Best Price in New Delhi, Delhi | Hi

Buy low price high frequency inverter in sagarpur, new delhi. high frequency inverter offered by hi-tech power solution is available with multiple payment options and easy delivery.

How High-Frequency Inverters Improve Energy Efficiency

4 days ago · How High-Frequency Inverters Enhance Energy Efficiency In the realm of energy conservation, high-frequency inverters emerge as game-changers, transforming conventional

Guide to Frequency Inverters: Optimizing Motor

Nov 13, 2024 · I. Introduction to Frequency Inverters (VFDs) Frequency inverters, also known as variable frequency drives (VFDs), are essential components in

High Frequency Power Inverters: A Guide To Modern Solutions

May 4, 2024 · High frequency power inverters have revolutionized the field of electrical conversion, enabling efficient and reliable power supply solutions for various applications. In

High-Frequency vs. Low-Frequency Inverters

High-Frequency Inverters: High-frequency inverters can handle moderate surges, but their surge capacity is generally lower than low-frequency inverters. They may struggle to run devices with

Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

6 FAQs about [Hg6600 high frequency inverter]

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

What is the difference between sigineer HF and low-frequency inverters?

The Sigineer low-frequency inverters can output a peak 300% surge power for 20 seconds, while high-frequency inverters can deliver 200% surge power for 5 seconds, check our HF solar power inverters. Low-frequency inverters take power impact through its big transformer which acts like a surge relief for the circuit.

What are the components of a high frequency inverter circuit?

The most important component of a high frequency inverter circuit is the transformer. This component is responsible for converting the DC current into AC power. Depending on the application, different types of transformers can be used, such as pulse width modulated (PWM), full wave, half wave, and peak-to-peak.

How do high frequency power inverters convert DC to AC?

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz. Low frequency inverter circuit diagram

What is a high frequency variable load inverter?

ut Pmax VINmax13:56MHz21:31kW375VIV. CONTROL SCHEMEA. Control ChallengesIn Section II the high frequency variable load inverter was modeled with each constituent inverter as an ideal voltage source that could drive any resistiv / inductive load, only sub-ject to maximum output voltage and current limits. However, real inverters h

Are high frequency inverter circuits safe?

High frequency inverter circuits also come with various safety features. These features are designed to protect the user from dangerous shocks, short circuits, and other potential accidents. Moreover, these units are often designed so that they can be easily repaired or even replaced if something goes wrong.

Learn More

- Full-bridge IGBT inverter high frequency

- High frequency 12v inverter

- High frequency inverter RV

- Freetown High Frequency Inverter

- Assembly of high power industrial frequency inverter

- Island electromagnetic wave high frequency inverter

- How many watts does a pure high frequency inverter have

- How much is the price of high frequency inverter in Ho Chi Minh Vietnam

- Inverter low frequency and high frequency

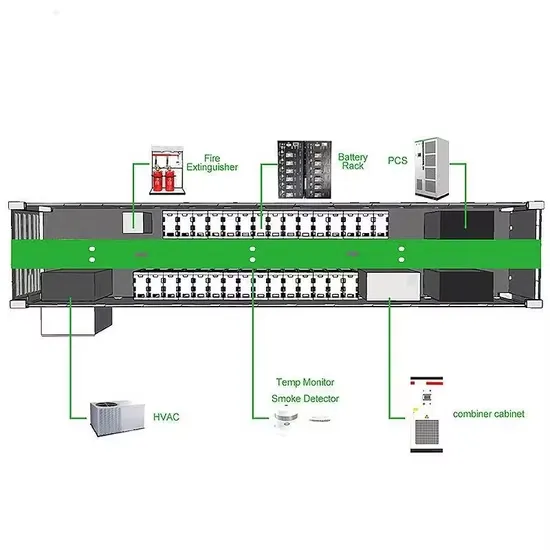

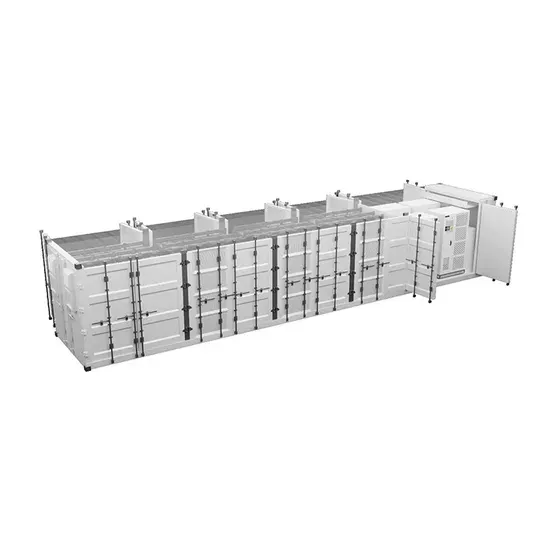

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.