A high switching frequency IGBT PWM rectifier/inverter system

The inverter uses an Undeland snubber together with a simple energy recovery circuit, which ensures reliable and efficient operation even for 20 kHz switching. The front end for the system

Modeling and simulation of three-phase IGBT full-bridge inverter

Aug 1, 2024 · This article focuses on the output characteristics of three-phase IGBT full bridge inverter circuits during high-frequency switching, comprehensively considering the model

Design Procedures and Prototyping of a Full-Bridge High Frequency

Dec 4, 2019 · Design Procedures and Prototyping of a Full-Bridge High Frequency Power Inverter Published in: 2019 IEEE 15th Brazilian Power Electronics Conference and 5th IEEE Southern

Experimental investigation of full bridge series resonant inverters

May 27, 2009 · In this paper, a full-bridge resonant-type IGBT inverter suitable for heating magnetic and nonmagnetic materials at high frequency is experimentally described.

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · Here H-bridge circuit converts battery DC voltage into AC using high frequency PWM (6 kHz to 20 KHz) thus feeding the 50-Hz transformer which Boost it to 120V/220V AC.

Analysis of High Frequency Characteristics of Power

Mar 13, 2019 · To analyze high frequency switching behavior of an inverter accurately, an accurate IGBT model is essential. In this study, an insulated gate bipolar transistor (IGBT) is

A new IGBT control and drive circuit for high-power full-bridge

Jun 1, 2013 · In this paper, aiming at the characteristics of high-power full-bridge inverter, a new IGBT control and drive circuit is designed, in which UCC3895, a phase shift and dead-time

Choose Your IGBTs Correctly for Solar Inverter Applications

May 18, 2025 · A typical implementation of a solar inverter employs a full-bridge topology using four switches (Fig. 2). Here, Q1 and Q3 are designated as high-side IGBTs while Q2 and Q4

An alternate hybrid PWM for uniform thermal sharing in

Feb 27, 2023 · A single-phase full-bridge voltage-source inverter (VSI) is a common power electronic converter employed in applications where DC-to-AC conversion is required. Its

Loss and efficiency comparisons of single-phase full

Feb 7, 2024 · Abstract The purpose of this study is to analyze the performances of the single-phase full-bridge inverter according to diferent switch structures and to propose a cost-efective

Modeling and simulation of three-phase IGBT full-bridge inverter

Aug 1, 2024 · Using the IGBT module parameter curve of Infineon''s FS400R07A1E3, the three-phase IGBT full bridge inverter circuit simulation during IGBT high-frequency switching is

Direct AC-AC Full Bridge Converter

Jan 7, 2017 · Finally, the full bridge inverter is used for high output power levels. The proposed converter uses a half bridge boost rectifier and a full bridge inverter for obtaining high output

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · This application report documents the implementation of the Voltage Fed Full Bridge isolated DC-DC converter followed by the Full-Bridge DC-AC converter using TMS320F28069

Dynamics of IGBT based PWM Converter A Case Study

Feb 4, 2019 · A 60 Hz, voltage source feeds a 50 Hz, 50 kW load through a double conversion converter. The 600V, 60 Hz voltage obtained at secondary of the Y connected transformer is

IGBT Technologies and Applications Overview: How and

Application Overview – Half Bridge High side IGBT always commutates with low side FWD and vice versa. IGBT turn-off generates over- or undervoltage (dep. on load-current direction)

A high switching frequency IGBT PWM rectifier/inverter system

Aug 6, 2002 · The inverter uses an Undeland snubber together with a simple energy recovery circuit, which ensures reliable and efficient operation even for 20 kHz switching. The front end

Design Procedures and Prototyping of a Full-Bridge High Frequency

Dec 4, 2019 · Nowadays, power electronics inverters are everywhere, from customer electronics to industry applications. In the heart of these converters there are discrete semiconductor

H series 1200 V IGBTs on 3-phase full-bridge DC-DC

In the full-bridge topology, the inverter stage includes four power transistor switches and four fast recovery diodes anti-parallel and co-packaged to each switch placed at the end of high

A Si IGBT and SiC MOSFET Hybrid Full-Bridge Inverter and Its

Nov 29, 2022 · A Si IGBT and SiC MOSFET hybrid full-bridge inverter and its modulation scheme are proposed in this paper. SiC MOSFETs are employed and all the high-frequency switching

Loss and efficiency comparisons of single-phase full-bridge inverters

Dec 27, 2023 · The purpose of this study is to analyze the performances of the single-phase full-bridge inverter according to different switch structures and to propose a cost-effective structure

Choose Your IGBTs Correctly for Solar Inverter Applications

May 18, 2025 · As can be seen in the table, a standard-speed IGBT has the lowest VCEON, but the slowest fall time compared to the other two fast and ultrafast planar IGBTs. The fourth

H series 1200 V IGBTs on 3-phase full-bridge DC-DC

In a main full-bridge inverter-based topology welding operation, the incoming AC 50/60 Hz main power (single or three-phase) is first rectified to DC and then is fed into the inverter section of

High-frequency full-bridge LLC resonant inverter with GaN

Dec 9, 2022 · In this paper, the development of a compact LLC resonant converter based on GaN devices and with output power up to 10 kW is described. The capability of 1 MHz operation

6 FAQs about [Full-bridge IGBT inverter high frequency]

How to analyze high frequency switching behavior of a high-power full-bridge inverter?

To analyze high frequency switching behavior of an inverter accurately, an accurate IGBT model is essential. In this study, an insulated gate bipolar transistor (IGBT) is modeled using datasheet and measurement data to analyze the high frequency characteristics of a high-power full-bridge inverter.

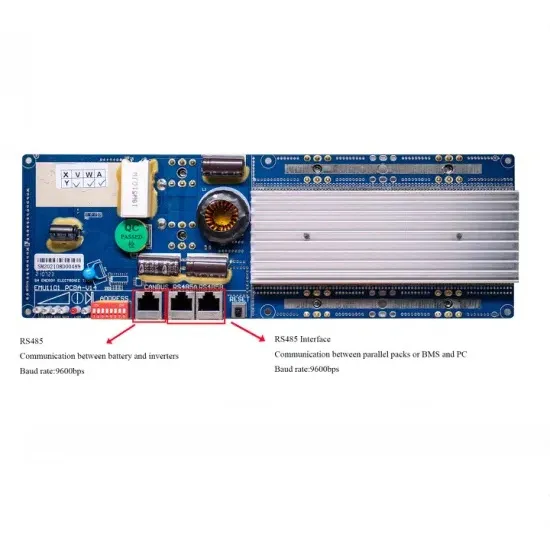

How to control a full bridge IGBT inverter?

To control the full bridge IGBT inverter, two gate driver PCBs are connected to each of the half bridges. The gate driver makes -5V and 15V as negative and positive gatevoltages. The control signals are generated by the DSP board and transmitted to the gate drivers.

What is a three-phase IGBT full-bridge inverter model?

The model employs the circuit-level calculation time-step T and the subcircuit-level calculation time-step t to deal with the accuracy and real-time performance of the simulation of the three-phase IGBT full-bridge inverter circuit during the switching state changes.

Which IGBT module is used for a bridge inverter?

For this purpose, the IGBT module F4-50R06E1A3, which has 4 IGBT dies and 4 freewheeling diodes, is used. Fig. 3 shows the full bridge inverter circuit of the IGBT module. A PCB test board for the IGBT module is designed to construct the measurement setup and precisely characterize the circuit parameters.

What is a full bridge inverter?

Full bridge inverter is a topology of H-bridge inverter used for converting DC power into AC power. The components required for conversion are two times more than that used in single phase Half bridge inverters. The circuit of a full bridge inverter consists of 4 diodes and 4 controlled switches as shown below.

What are the parameter characteristics of three-phase IGBT full bridge inverter circuits?

The parameter characteristics of three-phase IGBT full bridge inverter circuits in circuit composition are not completely consistent, but most of them are composed of the most basic passive components through different logical combinations.

Learn More

- Industrial frequency high frequency low frequency inverter

- The difference between inverter and high frequency power generation

- High frequency inverter has low frequency

- 1kW high frequency inverter power consumption

- Efficiency of high frequency inverter

- What is a high frequency inverter

- Berne high frequency inverter

- High frequency sine inverter

- Inverter high voltage main frequency or low voltage mixed frequency

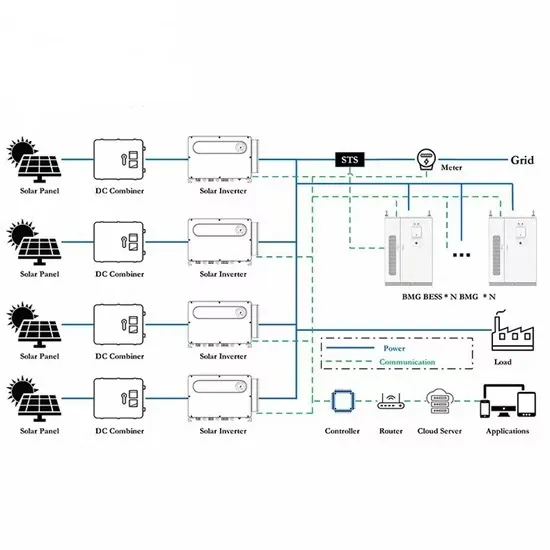

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.