LEAD ACID STORAGE CELL

Feb 4, 2025 · A lead acid cell is an electrochemical cell, comprising of a lead grid as an anode (negative terminal) and a second lead grid coated with lead oxide, as a cathode (positive

Electrochemical energy storage concept lead acid

This article provides an overview of the many electrochemical energy storage systems now in use, such as lithium-ion batteries, lead acid batteries, nickel-cadmium batteries, sodium-sulfur

A comprehensive review on the techno-economic analysis of

Feb 1, 2025 · This paper provides a comprehensive overview of the economic viability of various prominent electrochemical EST, including lithium-ion batteries, sodium-sulfur batteries, sodium

A review of battery energy storage systems and advanced battery

May 1, 2024 · This article provides an overview of the many electrochemical energy storage systems now in use, such as lithium-ion batteries, lead acid batteries, nickel-cadmium

Energy Storage with Lead–Acid Batteries

Jan 1, 2015 · As the rechargeable battery system with the longest history, lead–acid has been under consideration for large-scale stationary energy storage for some considerable time but

Lead batteries for utility energy storage: A review

Jul 13, 2017 · Keywords: Energy storage system Lead–acid batteries Renewable energy storage Utility storage systems Electricity networks Energy storage using batteries is accepted as one

Lead-Acid Batteries: A Cornerstone of electrical energy storage

Jan 16, 2025 · Lead-acid batteries have been a fundamental component of electrical energy storage for over 150 years. Despite the emergence of newer battery technologies, these

Grid-Scale Battery Storage: Frequently Asked Questions

Jul 11, 2023 · What is grid-scale battery storage? Battery storage is a technology that enables power system operators and utilities to store energy for later use. A battery energy storage

Optimized lead-acid grid architectures for automotive lead-acid

Mar 10, 2021 · Since the lead-acid battery invention in 1859 [1], the manufacturers and industry were continuously challenged about its future. Despite decades of negative predictions about

Technology: Lead-Acid Battery

Sep 15, 2024 · In this process, electrical energy is either stored in (charging) or withdrawn from the battery (discharging). There are two general types of lead-acid batteries: closed and

Lead-Acid Batteries: The Cornerstone of Energy Storage

Lead-acid batteries have their origins in the 1850s, when the first useful lead-acid cell was created by French scientist Gaston Planté. Planté''s concept used lead plates submerged in an

Electrochemical Energy Storage (EcES). Energy Storage in

Aug 11, 2023 · Electrochemical Energy Storage (EcES). Energy Storage in Batteries Electrochemical energy storage (EcES), which includes all types of energy storage in

Lead batteries for utility energy storage: A review

Feb 1, 2018 · Lead–acid batteries have been used for energy storage in utility applications for many years but it has only been in recent years that the demand for battery energy storage

Lead-Carbon Batteries toward Future Energy Storage:

Sep 19, 2022 · Abstract The lead acid battery has been a dominant device in large-scale energy storage systems since its invention in 1859. It has been the most successful commercialized

Energy Storage with Lead–Acid Batteries

Jan 1, 2015 · This chapter describes the fundamental principles of lead–acid chemistry, the evolution of variants that are suitable for stationary energy storage, and some examples of

Lecture 3: Electrochemical Energy Storage

Feb 4, 2025 · electrochemical energy storage system is shown in Figure1. Charge process: When the electrochemical energy system is connected to an external source (connect OB in

lead-aCid battery

May 25, 2020 · A lead-acid battery system is an energy storage system based on electrochemical charge/discharge reactions that occur between a positive electrode that contains lead dioxide

Lead-acid batteries for medium

Jan 1, 2015 · The lead-acid battery represents the oldest rechargeable battery technology. Lead-acid batteries can be found in a wide variety of applications, including small-scale power

Technology: Lead-Acid Battery

Sep 15, 2024 · Summary of the storage process When discharging and charging lead-acid batteries, certain substances present in the battery (PbO2, Pb, SO4) are degraded while new

Lead-Carbon Batteries toward Future Energy Storage: From

The lead acid battery has been a dominant device in large-scale energy storage systems since its invention in 1859. It has been the most successful commercialized aqueous electrochemical

6 FAQs about [Is lead-acid battery an electrochemical energy storage ]

How do lead-acid batteries work?

In this process, electrical energy is either stored in (charging) or withdrawn from the battery (discharging). There are two general types of lead-acid batteries: closed and sealed designs. In closed lead-acid batteries, the electrolyte consists of water-diluted sulphuric acid. These batteries have no gas-tight seal.

Does stationary energy storage make a difference in lead–acid batteries?

Currently, stationary energy-storage only accounts for a tiny fraction of the total sales of lead–acid batteries. Indeed the total installed capacity for stationary applications of lead–acid in 2010 (35 MW) was dwarfed by the installed capacity of sodium–sulfur batteries (315 MW), see Figure 13.13.

What is a lead acid battery?

A lead–acid battery is composed of: anode: sponge metallic lead; cathode: lead dioxide (PbO 2); electrolyte: dilute mixture of aqueous sulfuric acid. Applications are motive power in cars, trucks, forklifts, construction equipment, recreational water craft, and standby/backup systems. They are used mainly for engine batteries.

What are the disadvantages of lead-acid batteries?

Lead-acid batteries have a disadvantage, which is their relatively high weight and consequently lower specific energy in the range 30-50 Wh/kg. However, they are suitable for medium and large energy storage applications due to their good power parameters and low price.

What is electrochemical energy storage?

Electrochemical energy storage refers to all types of secondary batteries. These batteries convert the chemical energy contained in their active materials into electric energy through an electrochemical oxidation-reduction reverse reaction. At present, batteries are produced in many sizes for a wide spectrum of applications.

Are batteries suitable for electrochemical energy storage?

Batteries are suitable for electrochemical energy storage, but only for limited periods of time due to their self-discharge property and aging, which results in a decreasing storage capacity. For electrochemical energy storage, the specific energy and specific power are two important parameters.

Learn More

- Ladder lead-acid battery energy storage

- Sarajevo energy storage lead-acid battery manufacturer

- Liquid-cooled energy storage cabinet lead-acid battery

- Lead-acid battery energy storage readable voltage

- Energy storage lead-acid battery brand

- Energy storage lead-acid maintenance-free battery

- DaRan energy storage battery manufacturer

- India Mumbai energy storage battery quality merchants

- Chemical energy storage battery temperature control

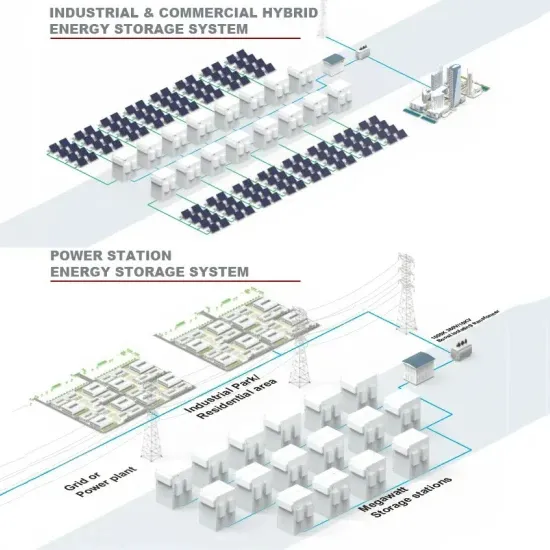

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.