What liquid-cooled energy storage is lead-acid battery

What is a Sealed Lead-Acid Battery: The Full Guide to SLA Batteries Lead-acid batteries have been a cornerstone of electrical energy storage for decades, finding applications in everything

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

Adopting a Liquid Cooling Battery Cabinet provides a multitude of benefits. The most significant is the enhancement of battery lifespan and performance. By maintaining a stable and uniform

Liquid-cooled energy storage lead-acid battery breaks

Each technology has its own merits As the world''''s leading provider of energy storage solutions, CATL took the lead in innovatively developing a 1500V liquid-cooled energy storage system in

Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · A well-integrated Liquid Cooled Energy Storage Cabinet doesn''t just run cooler—it runs smarter and lasts longer. In practical applications like

Lead-acid battery liquid-cooled energy storage charging

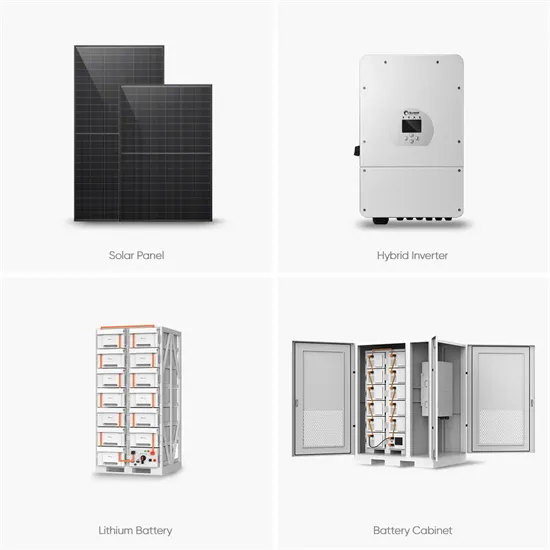

Liquid-cooled Energy Storage Cabinet. ESS & PV Integrated Charging Station. Standard Battery Pack . High Voltage Stacked Energy Storage Battery. Low Voltage Stacked Energy Storage

Liquid-cooled energy storage 110A lead-acid battery

Liquid Cooled Battery Energy Storage Systems Liquid Cooled Battery Pack 1. Basics of Liquid Cooling. Liquid cooling is a technique that involves circulating a coolant, usually a mixture of

Liquid Cooled Battery Energy Storage Systems

Jan 28, 2024 · In the ever-evolving landscape of battery energy storage systems, the quest for efficiency, reliability, and longevity has led to the development of more innovative

Liquid-cooled energy storage lead-acid battery screw

In summary, the technical specifications of liquid-cooled energy storage cabinet battery enclosures cover multiple aspects, including material, protection rating, size and shape,

Liquid-cooled Battery Cabinet | SHANGHAI ELECNOVA ENERGY STORAGE

The liquid-cooled battery cabinet adopts advanced cabinet-level liquid cooling and temperature balancing strategy. The cell temperature difference is less than 3°C, which further improves

Liquid-cooled energy storage lead-acid battery exhaust

The lead acid battery has been a dominant device in large-scale energy storage systems since its invention in 1859. It has been the most successful commercialized aqueous electrochemical

Liquid-cooled energy storage special lead-acid battery

Liquid air energy storage (LAES) is becoming an attractive thermo-mechanical storage solution for decarbonization, with the advantages of no geological constraints, long lifetime

Liquid-cooled energy storage special lead-acid battery

Lead acid batteries are proven energy storage technology, but they''''re relatively big and heavy for how much energy they can store. Deep cycle lithium ion batteries are more expensive than

Professional lead-acid battery liquid-cooled energy

Lead-Acid Battery Consortium, Durham NC, USA A R T I C L E I N F O Article Energy history: Received 10 October 2017 Received in revised form 8 November 2017 Accepted 9 November

Liquid cooled energy storage lead acid battery 35a

Discover Top Suppliers for Outdoor liquid cooled energy storage Converged cabinet and ESS Container Battery Products at Sundtapv . Our High-Quality Items Have Found Homes in Over

Liquid cooled energy storage battery Cyprus lead acid

The energy storage landscape is rapidly evolving, and Tecloman''''s TRACK Outdoor Liquid-Cooled Battery Cabinet is at the forefront of this transformation. This innovative liquid cooling

Liquid-cooled energy storage lead-acid battery fashion

The Rise of 314Ah LiFePO4 Cells: A New Era of Large-Capacity Battery The EnerD series products adopt the new generation of 314Ah cells for energy storage, equipped with Ningde

215KWh/232KWh Liquid Cooled Energy Storage Systems

Jul 15, 2025 · Oregon (SY)Amperex offers high-capacity liquid cooled energy storage systems ideal for industrial and commercial applications. With 30+ years of battery innovation, we

Liquid Cooling Battery Cabinet Efficiency & Design

Unlike air cooling, which relies on circulating air to dissipate heat, liquid cooling uses a specialized coolant that flows through pipes or plates integrated within the battery cabinet. This fluid has a

SHANGHAI ELECNOVA ENERGY STORAGE CO., LTD.

Compared to traditional lead-acid batteries used as backup power solutions, energy storage integrated cabinets offer higher system integration, greater safety at all times, and improved

Liquid-Cooled Battery Storage Cabinets: The Next Frontier in Energy

Why Thermal Management Could Make or Break Renewable Energy Adoption As global renewable capacity surges past 4,500 GW, a critical question emerges: How can we prevent

Liquid Cooling Energy Storage Cabinet: The Future of

Jan 31, 2025 · These cabinets aren''t just metal boxes; they''re climate-controlled sanctuaries for batteries, combining cutting-edge thermal management with space-saving designs. Let''s

Liquid-cooled energy storage large lead-acid battery

How to Choose the Best Liquid-cooled Battery Cabinet The performance and capacity of the battery are the core indicators of the liquid-cooled battery cabinet. It is crucial to understand

Liquid-cooled energy storage battery lead-acid battery

Daily charging of liquid-cooled energy storage lead-acid batteries Energy Storage with Lead–Acid Batteries . The fundamental elements of the lead–acid battery were set in place over 150 years

Liquid-Cooled Battery Storage Cabinets: The Next Frontier in Energy

As global renewable capacity surges past 4,500 GW, a critical question emerges: How can we prevent energy storage systems from becoming their own worst enemies? The answer might

Liquid-cooled Energy Storage Cabinet

• Intelligent Liquid Cooling, maintaining a temperature difference of less than 2℃ within the pack, increasing system lifespan by 30%. • High-stability lithium iron phosphate cells. • Three-level

Energy storage lead-acid battery made into liquid-cooled energy storage

Hot Energy Storage? Liquid Metal Battery Explained Ambri''''s liquid metal battery is made of a liquid calcium alloy anode, a molten salt electrolyte and a cathode comprised of solid particles

6 FAQs about [Liquid-cooled energy storage cabinet lead-acid battery]

What is a lead acid storage battery?

Lead Acid Storage Batteries is an electro-chemical system that converts electrical energy into direct current electricity. It is also known as storage batteries and has wide applications in Automobiles, UPS/Inverters, Tract

What is included in a battery management system?

In addition to battery cells, there are switch-disconnectors, contactors, sensors, sampling lines, battery management systems, as well as control units being integrated into the same battery rack. BESS employs a sophisticated, multilevel battery management system (BMS) for system monitoring and control. Each battery management system including:

How many temperature detectors does a battery module have?

Each battery module has 8 temperature detectors. There are 2 racks that fit in a single battery cabinet, 9 slots in each battery rack to accommodate 8 battery modules and total 1 BSPU (Battery Switch & Protective Unit). Racks are connected in parallel and paired with a system BMS to meet the power and energy requirements of the application at hand.

What is a battery rack?

Each battery rack contains a rack-level BMS. The positive (+) and negative (-) terminals of the battery modules are clearly marked and are designed for the convenience of connection, visual check, examine, and repair. The external casing is made of metal covered by insulating materials.

What is a battery module made of?

The external casing is made of metal covered by insulating materials. For example, the top cover is made of PP, the bottom base is made of aluminum. The copper bars and screws are connected internally to prevent short circuit to ensure the electrical safety of the battery module. Each battery module has 8 temperature detectors.

How many battery cells are in a battery rack?

All wire connections are placed on the front side of the rack to allow easy installation and maintenance. Since each battery rack hosts 8 battery modules and each battery module has 52 battery cells, each battery Rack has a total of 416 battery cells connected in series.

Learn More

- Liquid-cooled energy storage battery cabinet assembly

- String type liquid-cooled energy storage battery cabinet

- Liquid-cooled energy storage battery cabinet installation in Portugal

- American Battery Energy Storage Container Cabinet Company

- How is the Togo lithium battery energy storage cabinet

- Energy storage battery cabinet warranty period

- Performance of energy storage battery cabinet

- Kuwait outdoor communication battery cabinet energy storage battery website

- Bern Energy Storage Cabinet Battery Assembly

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.