Microsoft Word

Oct 1, 2020 · Unlike Li-ion and other solid-state batteries which store electricity or charge in electrodes made from active solid materials, Redox Flow Batteries (RFB) work like a reversible

Why Temperature Cutting-off Protection Matters for Lithium Batteries

Mar 3, 2025 · Lithium batteries are at the core of modern technological advancements, powering everything from smartphones and laptops to electric vehicles and renewable energy storage

Thermal effects of solid-state batteries at different temperature

Apr 1, 2024 · Solid-state batteries, which show the merits of high energy density, large-scale manufacturability and improved safety, are recognized as the leading candidates for the next

Thermal Management of Chemical Energy Storage Batteries

When the battery temperature rises, the PCM absorbs the heat and changes its phase, effectively stabilizing the temperature. PCMs can be used alone or in combination with other cooling

Navigating challenges in large-scale renewable energy storage

Dec 1, 2024 · With the growing global concern about climate change and the transition to renewable energy sources, there has been a growing need for large-scale energy storage than

Integrated cooling system with multiple operating modes for temperature

Apr 15, 2025 · The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Smart design and control of thermal energy storage in low-temperature

Sep 1, 2022 · The present review article examines the control strategies and approaches, and optimization methods used to integrate thermal energy storage into low-temperature heating

Preventing the Next Battery Incident: Rethinking Battery Energy Storage

May 29, 2025 · As battery energy storage systems expand, recent fires and explosions prove compliance isn''t enough. James Close and Edric Bulan say only a layered, system-wide safety

Understanding Battery Types, Components and

May 30, 2024 · Batteries have become an integral part of our everyday lives. In this article, we will consider the main types of batteries, battery components

A Review of Emerging Energy Storage Technologies

Jun 28, 2018 · 3 Key Findings A number of these emerging energy-storage technologies are conducive to being used at the customer level. They represent significant opportunities for grid

Monitoring and control of internal temperature in power batteries

Feb 1, 2025 · Herein, a comprehensive review of the latest research advancements in internal temperature monitoring and control for batteries is provided.

A critical review of thermal management systems for lithium-ion batteries

Aug 19, 2025 · Lithium-ion batteries have become the preferred power source for electric vehicles with superior properties and excellent performance. Chemical reactions within the battery

Battery technologies for grid-scale energy storage

Jun 20, 2025 · In this Review, we describe BESTs being developed for grid-scale energy storage, including high-energy, aqueous, redox flow, high-temperature and gas batteries.

A thermophysical battery for storage-based climate control

Mar 1, 2017 · Thermal energy storage-based climate control offers a promising strategy to address the rising demand for energy. While allowing higher flexibility in energy usage, it can

All-temperature area battery application mechanism,

Jul 10, 2023 · Further applications of electric vehicles (EVs) and energy storage stations are limited because of the thermal sensitivity, volatility, and poor durability of lithium-ion batteries

A review of battery energy storage systems and advanced battery

May 1, 2024 · Lithium batteries are becoming increasingly important in the electrical energy storage industry as a result of their high specific energy and energy density. The literature

Energy Storage Safety Strategic Plan

May 5, 2024 · The Department of Energy Office of Electricity Delivery and Energy Reliability Energy Storage Program would like to acknowledge the external advisory board that

Advances in battery thermal management: Current

Aug 1, 2024 · Sustainable thermal energy storage systems based on power batteries including nickel-based, lead-acid, sodium-beta, zinc-halogen, and lithium-ion, have proven to be

Recent advancement in energy storage technologies and

Jul 1, 2024 · • This review concisely focuses on the role of renewable energy storage technologies in greenhouse gas emissions. • Different energy storage technologies including mechanical,

Temperature effect and thermal impact in lithium-ion batteries

Dec 1, 2018 · Lithium-ion batteries, with high energy density (up to 705 Wh/L) and power density (up to 10,000 W/L), exhibit high capacity and great working performance. As rechargeable

6 FAQs about [Chemical energy storage battery temperature control]

What is battery thermal management?

In this Perspective, we discuss battery safety from a thermal point of view and emphasize the importance of battery thermal management. Battery thermal management ensures that electrochemical reactions occur within an optimal temperature range, suppressing side reactions and delaying or even preventing thermal runaway.

How can thermal management improve battery safety?

Understanding thermal runaway and propagation mechanisms in various systems and developing corresponding prediction technologies are essential for improving battery safety. From a thermal perspective, thermal management approaches capable of interrupting the chain exothermic reactions help to address thermal runaway of batteries.

How can a cooling spray improve the thermal safety of batteries?

In addition to thermal management strategies, improving the thermal stability and flame retardancy of internal battery materials is a critical approach to enhancing the thermal safety of batteries. In terms of fire prevention, cooling sprays have proven to be effective.

How does battery temperature management work?

Traditional battery temperature management has primarily relied on external control technologies such as air cooling, liquid cooling systems, and external low-temperature heating systems [172, 173]. These methods regulate temperature through thermal exchange between the battery casing and the environment.

What is battery thermal safety?

The control of heat generation, effective thermal management and robust fire suppression strategies are key to ensure battery thermal safety and will have a crucial role in the development and large-scale application of batteries. Excessive heat generation in batteries can result in thermal runaway and fires incidents.

What is internal temperature control in power batteries?

Challenges of internal temperature control in power batteries Internal temperature control is considered a crucial factor for ensuring the performance and safety of power batteries, especially when subjected to extreme high or low temperatures.

Learn More

- Battery energy storage system main equipment main control board for communication base station

- Energy storage cabinet temperature control system price

- Energy storage battery capacity temperature compensation coefficient

- Indian battery energy storage battery in low temperature environment

- Energy storage container temperature control system

- Chemical protection lithium battery energy storage cabinet base station

- Temperature control system of energy storage power station products

- Huawei s ultra-low temperature energy storage battery

- Is the energy storage battery cabinet constant temperature

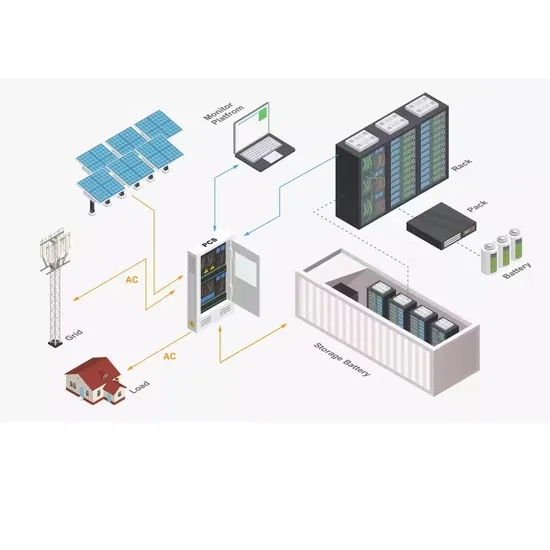

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.