Adaptive multi-temperature control for transport and

Dec 4, 2023 · The transportation of essential items, such as food and vaccines, often requires adaptive multi-temperature control to maintain high safety and effi-ciency. While existing

Shipping Container Energy Storage System Guide

Apr 11, 2024 · Essential modifications for a shipping container energy storage unit include the installation of insulation to control temperature, the implementation

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · Battery Energy Storage System (BESS) containers are a cost-effective and modular solution for storing and managing energy generated from renewable sources. With their ability

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

Jun 8, 2023 · The Battery Energy Storage System (BESS) is a versatile technology, crucial for managing power generation and consumption in a variety of applications. Within these

Blogs, News, Events

Jan 19, 2023 · The temperature control system is an important link to ensure the normal operation of lithium battery energy storage. At present, air cooling and liquid cooling technologies are the

Container energy storage temperature control

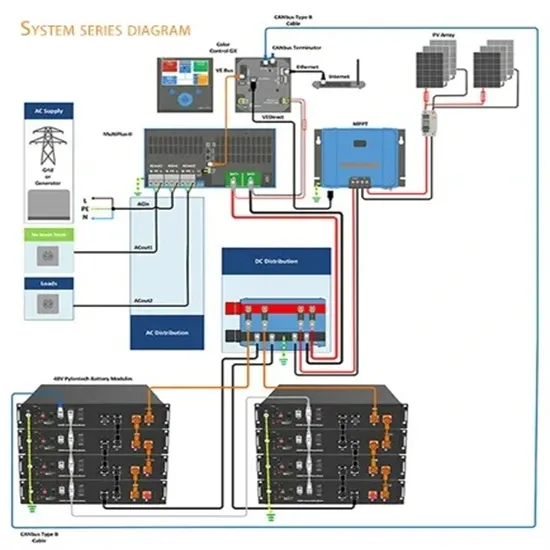

Using a 20-foot or 40-foot outdoor container, the protection level is IP54, and it is composed of an energy storage converter, a lithium-ion battery system, a battery management system (BMS),

Adaptive multi-temperature control for transport and storage containers

Sep 6, 2023 · In this study, we present an adaptive multi-temperature control system using liquid-solid phase transitions to achieve highly effective thermal management using a pair of heat

Integrated cooling system with multiple operating modes for temperature

Apr 15, 2025 · In winter, low condensing temperature heat pump technology is used to replace traditional PTC electric heating, which has good energy saving benefits. The proposed

TEMPERATURE CONTROL: THE CRUCIAL THERMAL

Jun 9, 2023 · Temperature control is a fundamental aspect of thermal management in energy storage systems. By maintaining optimal operating temperatures, energy storage systems can

Battery Management System (BMS) in Battery Energy Storage Systems

Sep 15, 2024 · Learn about the role of Battery Management Systems (BMS) in Battery Energy Storage Systems (BESS). Explore its key functions, architecture, and how it enhances safety,

6 FAQs about [Energy storage container temperature control system]

What is a containerized energy storage battery system?

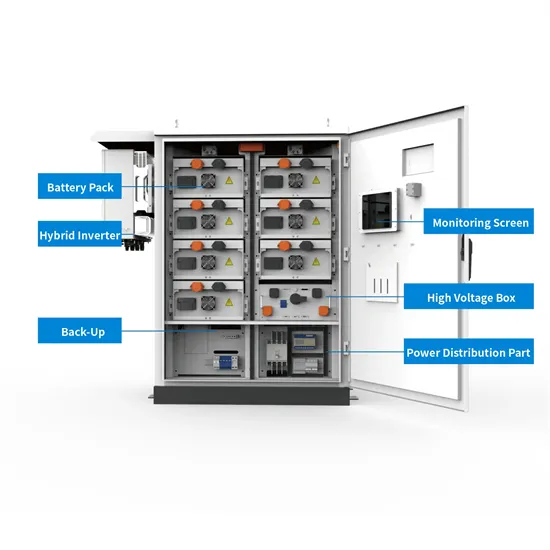

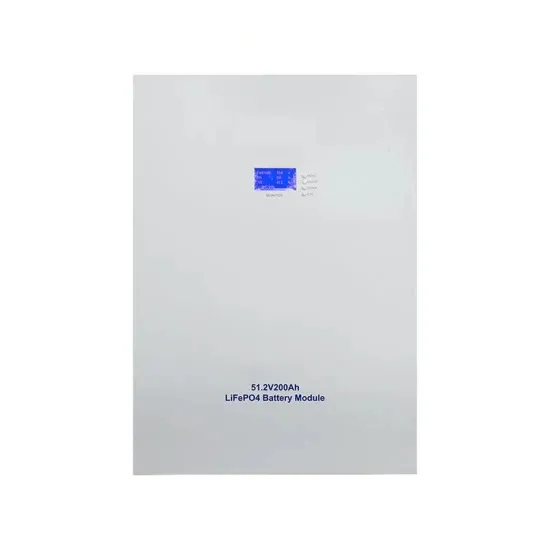

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

Are air cooling systems good for energy storage?

Air cooling systems, favoured for their low cost, simplicity, and space efficiency, are widely utilized in practical energy storage applications . However, they exhibit lower efficiency at high discharge rates and temperatures, resulting in uneven battery temperatures [16, 17].

How to choose a commercial thermal insulating container?

Select a commercial thermal insulating container of an appropriate size for their storage. Leave sufficient space for the integration of a multi-temperature control system. Thus, the structural parameters of the system \ ( ( {d}_ {\epsilon,\ {i,j\}})\) can be established.

Does transportation need a temperature control system?

However, the need for efficiency and convenience in transportation restricts the application of some temperature control technologies that necessitate additional mechanical equipment or real-time external energy input, such as vapor compression refrigeration and electric heating.

Can a PCM control the temperature of a storage space?

This suggests that when the temperature differences among the storage spaces are significant, more energy may be employed to negate the negative effects of temperature interactions. Moreover, a specific type of PCM can only strictly control the temperature of a single zone 19, 20, 21, 28, 29, 30.

What is a multi-temperature maintenance container?

Compared to a container without AMTC and with LTCM (low thermal conductivity materials), our multi-temperature maintenance container reduces temperature variations by up to 94.7% and 85.9%, respectively, highlighting the effectiveness of AMTC in ensuring reliable transportation of goods.

Learn More

- Energy storage container temperature control system

- Energy storage cabinet temperature control system price

- Container energy storage system control cabinet

- Chemical energy storage battery temperature control

- Dual system energy storage temperature control

- What are the temperature control devices for solar energy storage cabinets

- Energy storage temperature control products

- Energy storage container photovoltaic solar energy ranking

- Tunisia container energy storage power

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.