Lithium-ion battery capacity estimation based on battery

Feb 15, 2022 · Accurate estimation of battery actual capacity in real time is crucial for a reliable battery management system and the safety of electrical vehicles. In this paper, the battery

SR-CKF algorithm-based state-of-charge estimation of

Jul 30, 2025 · Considering the significant impact of temperature and current multiplicity on LIB performance, it incorporates dual compensation for temperature and current multiplicity, an

State-of-charge estimation of lithium ion batteries based on

Jul 1, 2021 · The influence of temperature on battery capacity, parameters and SOC-OCV relationship is considered. Experiments and simulations prove that the algorithm has good

Temperature effect and thermal impact in lithium-ion batteries

Dec 1, 2018 · Lithium-ion batteries, with high energy density (up to 705 Wh/L) and power density (up to 10,000 W/L), exhibit high capacity and great working performance. As rechargeable

What drives capacity degradation in utility-scale battery energy

Mar 1, 2022 · Battery energy storage systems (BESS) find increasing application in power grids to stabilise the grid frequency and time-shift renewable energy production. In this study, we

Gel and AGM Batteries

Feb 8, 2024 · The recommended temperature compensation for Victron VRLA batteries is -4 mV / Cell (-24 mV /°C for a 12V battery). The centre point for temperature compensation is 25°C /

Enhancing State of Charge Prediction in Lithium

Apr 17, 2025 · 1. Introduction Lithium-ion batteries are widely used in various applications, including electric vehicles and energy storage systems, due to their high energy density and

Multi-timescale capacity configuration optimization of energy storage

Jun 5, 2023 · Case study on the capacity configuration of the molten-salt heat storage equipment in the power plant-carbon capture system shows that the proposed multi-timescale capacity

Fast and high-precision online SOC estimation for improved

Apr 15, 2024 · This model incorporates temperature correlation coefficients and the electrical characteristics of lithium-ion batteries at various temperatures. Subsequently, a combined

SECTION 6: BATTERY BANK SIZING PROCEDURES

Jun 14, 2022 · Autonomy Length of time that a battery storage system must provide energy to the load without input from the grid or PV source Two general categories: Short duration, high

A Battery Capacity Estimation Method Using Surface Temperature

Oct 14, 2021 · Accurate estimation of the actual battery capacity is crucial for a reliable battery management system. In this paper, the battery capacity is estimated based o

Battery Temperature Compensation Calculator

Mar 25, 2025 · FAQs About Battery Temperature Compensation Q1: What happens if I don''t compensate for temperature? Without compensation, batteries may experience: Overcharging

State of Charge Estimation of Lithium Batteries Based on

Apr 17, 2025 · hium-ion batteries is crucial for efficiently managing and safely operating energy storage sys. s, particularly in electric and hybrid electric vehicles. Temperature fluctuations...

State of Charge Estimation for Lithium-Ion Battery with a

Oct 11, 2017 · This paper proposes a SOC estimator based on a new temperature-compensated model with extended Kalman Filter (EKF). The open circuit voltage (OCV), capacity, and

Capacity estimation of Lithium-ion batteries based on

To overcome this challenge, this paper proposes an adaptive capacity estimation method based on a discharge rate compensation model. Initially, a comparative analysis was conducted to

Grid-Scale Battery Storage: Frequently Asked Questions

Jul 11, 2023 · What is grid-scale battery storage? Battery storage is a technology that enables power system operators and utilities to store energy for later use. A battery energy storage

Thermal analysis of high specific energy NCM-21700 Li-ion battery

May 30, 2024 · Lithium-ion (Li-ion) batteries, particularly the high specific energy Nickel-Cobalt-Manganese (NCM)-21,700 battery cell, have emerged as the leading energy storage solution

Quantitative Efficiency and Temperature Analysis of

Oct 25, 2020 · ency and battery temperature rise in battery-alone system, passive, battery semiactive, capacitor semiactive hybrid energy storage systems (H SSs). First the system

energy storage lithium battery temperature compensation coefficient

Therefore, the paper introduces a temperature compensation coefficient to modify the relationship between the actual capacity and the rated capacity of the battery. $$mathrm {Q}= {eta }_ {T}

All-temperature area battery application mechanism,

Jul 10, 2023 · Further applications of electric vehicles (EVs) and energy storage stations are limited because of the thermal sensitivity, volatility, and poor durability of lithium-ion batteries

Machine Learning-Based Compensation for Temperature

May 26, 2025 · To address this gap, this study introduces a machine learning-based framework for SOC estimation that explicitly compensates for temperature variations. The proposed

Monitoring and control of internal temperature in power batteries

Feb 1, 2025 · The thermal characteristics and temperature sensitivity of batteries are introduced first, followed by a detailed discussion of various internal temperature monitoring technologies,

Online evaluation method for lithium battery capacity fading

May 1, 2025 · In response to the accurate and rapid prediction of capacity fading in lithium-ion batteries, this paper proposed an online evaluation method for lith

Battery Temperature Compensation Calculator

Mar 25, 2025 · The relationship between temperature and charging voltage follows the formula: [ V_c = V_n + (T_c times (T - 25)) ] Where: (V_c) is the compensated voltage. (V_n) is the

6 FAQs about [Energy storage battery capacity temperature compensation coefficient]

Is a battery capacity estimation method feasible under constant-current charge scenario?

Developed a capacity estimation method under constant-current charge scenario. Validated the feasibility based on aging data from two different batteries. Accurate estimation of battery actual capacity in real time is crucial for a reliable battery management system and the safety of electrical vehicles.

How is battery capacity estimated under constant-current charge scenario?

In this paper, the battery capacity is estimated based on the battery surface temperature change under constant-current charge scenario. Firstly, the evolution of the smoothed differential thermal voltammetry (DTV) curves throughout the aging process is analyzed.

Does temperature affect battery SoC estimation accuracy?

Many studies on battery SOC estimation have been investigated recently. Temperature is an important factor that affects the SOC estimation accuracy while it is still not adequately addressed at present. This paper proposes a SOC estimator based on a new temperature-compensated model with extended Kalman Filter (EKF).

What is a SoC estimator based on a temperature-compensated model?

This paper proposes a SOC estimator based on a new temperature-compensated model with extended Kalman Filter (EKF). The open circuit voltage (OCV), capacity, and resistance and capacitance (RC) parameters in the estimator are temperature dependent so that the estimator can maintain high accuracy at various temperatures.

How accurate is battery SoC estimation?

Accurate estimation of the state of charge (SOC) of batteries is crucial in a battery management system. Many studies on battery SOC estimation have been investigated recently. Temperature is an important factor that affects the SOC estimation accuracy while it is still not adequately addressed at present.

How did a battery surface temperature change over a certain voltage range?

Introduced battery surface temperature change over certain voltage range as FoI. Determined voltage range based on differential thermal voltammetry analysis. Utilized temperature variation transformation to reduce initial inconsistency. Developed a capacity estimation method under constant-current charge scenario.

Learn More

- What is the energy storage capacity of the battery

- Azerbaijan battery energy storage system capacity

- Vietnam Ho Chi Minh large capacity energy storage battery

- Vanadium battery energy storage capacity

- What is the capacity of the container photovoltaic energy storage battery warehouse

- Kuala Lumpur large capacity energy storage battery

- West Asia large capacity energy storage battery

- Romania battery energy storage battery in low temperature environment

- Gaborone large capacity energy storage battery

Industrial & Commercial Energy Storage Market Growth

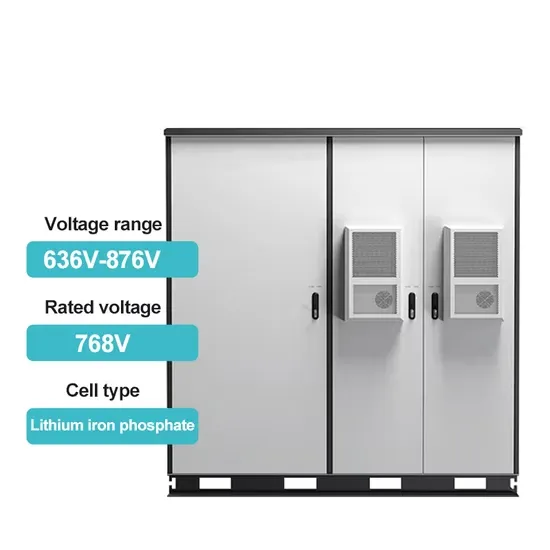

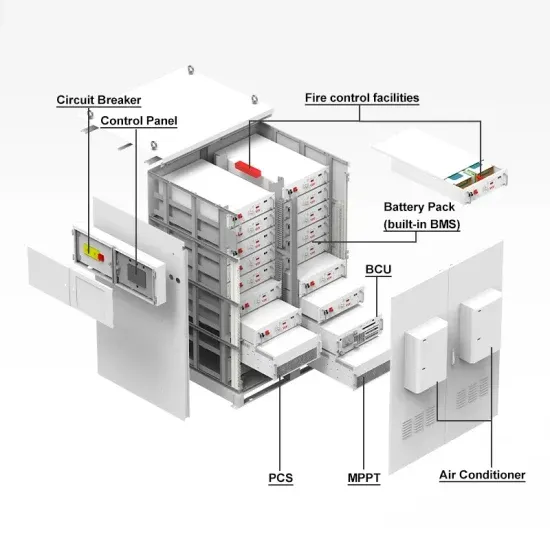

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.