Battery Cabinet Ventilation Design | HuiJue Group E-Site

Feb 27, 2023 · As lithium-ion batteries dominate energy storage, battery cabinet ventilation design has emerged as a critical engineering challenge. Did you know a 10°C temperature rise above

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Air cooling and heat dissipation performance of multi-layer battery

A simulation analysis was conducted on the air cooling and heat dissipation performance of a single-layer battery cabinet. This is based on the fact that each layer of the battery cabinet has

电气工程学报-年, 第卷, 第期

Nov 1, 2021 · Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the

Battery cabinet with heat dissipation structure

The utility model provides a heat radiation structure''s battery cabinet, belong to battery cabinet technical field, after solving the full storage battery in the battery cabinet, the battery is given

Study on performance effects for battery energy storage

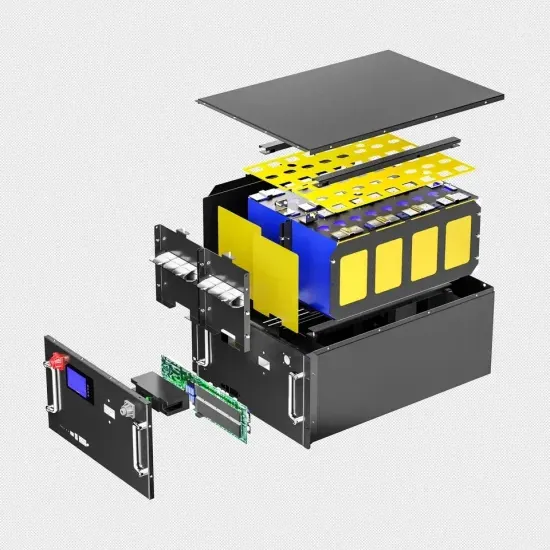

Feb 1, 2025 · The interior of the battery storage cabinet includes brackets, cables, battery modules, various sensors and switches, etc. It is challenging to design heat dissipation in such

How to design an energy storage cabinet: integration and

Jan 3, 2025 · Efficient heat dissipation design: Lithium batteries and inverters will generate a certain amount of heat during operation, so the energy storage cabinet requires an effective

电化学储能系统电池柜散热的影响因素分析-【维普期刊官网

WebIM,接待电化学储能系统电池柜散热的影响因素分析 认领 被引量: 5 Analysis of Influencing Factors of Battery Cabinet Heat Dissipation in Electrochemical Energy Storage

Energy storage battery cabinet heat dissipation

Therefore, a lithium-ion battery energy storage cabin requires an efficient ventilation condition to ensure fire safety. This work investigates the effects of ventilation

Study on the thermal interaction and heat dissipation of

Dec 1, 2017 · Because the distance among battery cells is only a few millimeters, the thermal status of battery would directly influent the current efficiency and battery life. In order to

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Explore the essential role of battery storage cabinets in modern energy systems, highlighting their design, safety features, and applications

Battery Cabinet Ventilation: The Critical Nexus of Safety and

What if tomorrow''s battery cabinets don''t need active ventilation at all? Research teams at MIT are exploring passive radiative cooling films that reportedly achieve 10W/m² of heat dissipation

Ventilation condition effects on heat dissipation of the

Nov 1, 2024 · Therefore, a lithium-ion battery energy storage cabin requires an efficient ventilation condition to ensure fire safety. This work investigates the effects of ventilation mode,

Cabinet Energy Storage System Wind Cooling

In Germany, where solar capacity grew 12% last year, over 30% of battery failures trace back to inadequate cooling. Traditional liquid-cooled cabinets work, sure, but they''re sort of like using

Energy storage battery cabinet heat dissipation

About Energy storage battery cabinet heat dissipation As the photovoltaic (PV) industry continues to evolve, advancements in Energy storage battery cabinet heat dissipation have become

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

The electrochemical energy storage system is an important grasp to realize the goal of double carbon. Safety is the lifeline of the development of electrochemical energy storage system.

Energy storage battery cabinet heat dissipation

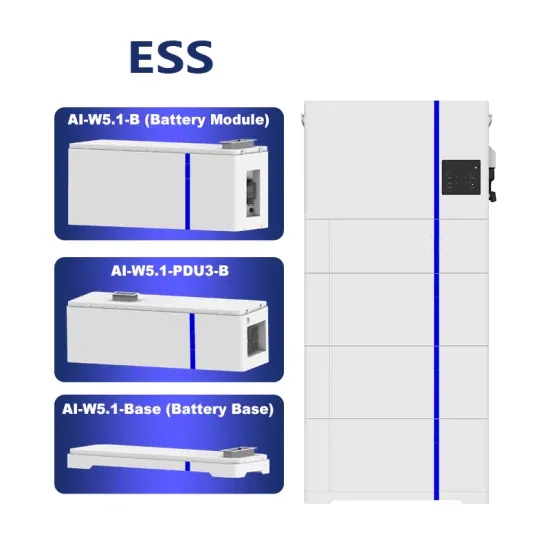

The 115kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS (Battery

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · Heat dissipation from Li-ion batteries is a potential safety issue for large-scale energy storage applications. Maintaining low and uniform temperature distribution, and low

Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit

Study on performance effects for battery energy storage

Feb 1, 2025 · In this section, the lithium ternary battery energy storage cabinet under the conditions of fixed air supply temperature and 2C discharge rate, and four inlet air flow rates of

4 FAQs about [Battery cabinet wind dissipation]

Does guide plate influence air cooling heat dissipation of lithium-ion batteries?

Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling.

What is lithium-ion battery energy storage cabin?

Lithium-ion battery energy storage cabin has been widely used today. Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat.

How to improve the air cooling effect of battery cabin?

The air cooling effect of battery cabin was improved by adding guide plate. There is better consistency between the modules and the modules can operate at more appropriate environment temperature. Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence.

How to simulate a battery cabin?

Firstly, a simulation model is established according to the actual battery cabin, which divided into two types: with and without guide plate. Then, at the environment temperature of 25°C, the simulation air cooling experiment of the battery cabin was carried out. The working condition of module was 1C, and the air speed was set to 4m/s.

Learn More

- Wind power in battery cabinet

- UPS battery cabinet is 3p wind power

- Battery cabinet system status

- Can the distribution box be installed in the battery cabinet

- How to measure the capacitive coupling of the battery cabinet

- Check the quality of the battery cabinet

- Windhoek environmentally friendly battery cabinet retail

- Nickel-cadmium battery cabinet

- Riga Energy Storage Cabinet Battery Assembly

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.