How does a power distribution box (DB box)

6 days ago · When a short circuit arises, the electrical distribution board (DB box) swiftly cuts off the power supply. With features like residual current circuit

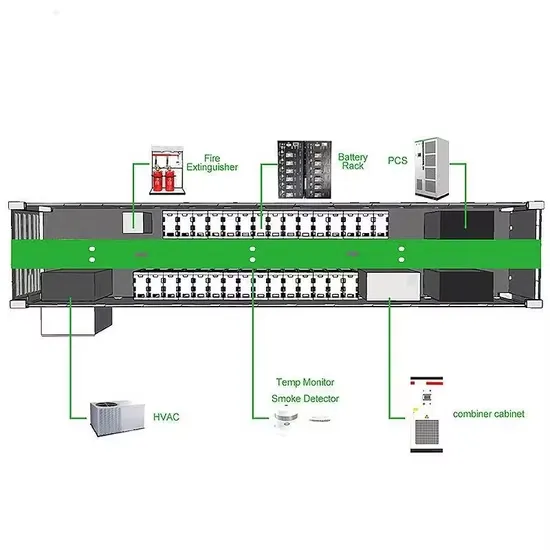

373kWh Liquid Cooled Energy Storage System

4 days ago · Each battery cabinet includes an IP56 battery rack system, battery management system (BMS), fire suppression system (FSS), HVAC thermal management system and

Power distribution cabinet installation method

Aug 14, 2019 · The distribution box should be installed in a safe, dry and easy-to-operate place. If there is no special requirement for the design, the height of

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Install the frame ground landing point adapter P/N 556872 to the left or right side of the battery cabinet, as shown in Figure 5. Installing P/N 556872 Frame Ground Landing Point

Solar Battery Cabinet Equipment Enclosures for on-grid or

The NEMA type outdoor lithium battery enclosure can effectively control the inner ideal temperature of the cabinet and make the battery run in an ideal temperature condition.

Battery Cabinet

Feb 28, 2025 · Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the

The difference between distribution box, power distribution

Jul 24, 2019 · It is usually installed in substations, power distribution rooms, etc. In addition to the functions, installation environment, internal structure and controlled objects, the distribution

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

NetSure™ -48 VDC Distribution Cabinet Assemb

Aug 11, 2017 · Kit P/N 10012729 provides Spec. No. 548066 Distribution Cabinet Assembly and right angle lug adapter P/N 545405 factory furnished and installed on all distribution positions.

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · There may be multiple ways to configure the cabinet, so consider all possible options. For instance, if a battery, rack and charger are required the system can be designed

PDU8000 配电箱-T 快速指南 (02409480)

Sep 21, 2023 · C:02409480;M:PDU8000-0016A2-CB9013 Tools / 安装工具 5 Installing a Power Distribution Box / 安装配电箱 PDU8000 Power Distribution Box-T Quick Guide 5.1 Checking

Installation specification for UPS battery cabinets and racks

Aug 7, 2024 · UPS battery cabinet and battery rack installation specifications. UPS battery cabinet is an intelligent power distribution cabinet that comprehensively collects all energy data for the

Choosing the Right Lithium Ion Battery Cabinet:

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

164201690_Rev_3.book

May 2, 2022 · The cabinet matches the UPS cabinet in style and color, and can be installed in line-up-and-match or standalone configurations. Figure 1-1 shows the Eaton 9390 40–80 kVA

The installation requirements for the distribution box

The battery pack needs to be installed in the IT cabinet to the right of the Converged Cabinet. If no smart cooling product is installed in the IT cabinet, install battery packs from bottom to top

Eaton EBC Installation and Operation Manual

Sep 2, 2024 · The EBC is designed to be installed in a line-up-and-match or standalone configurations. In line-up-and-match configurations power wiring may be routed either external

Avaya extended battery cabinet (EBC) installation guide

Jun 10, 2023 · Introduction This manual is intended to assist with the site preparation and installation of a Power Battery Co. CR-series battery cabinet with an Avaya UPS. It is

Overview of basic knowledge of distribution box and distribution cabinet

The distribution box is divided into power distribution box and lighting distribution box, which is the last level equipment of the distribution system. The distribution box is to assemble the

BC-1(R) Battery Cabinet Installation Sheet

Feb 23, 2023 · The BC-1(R) Battery Cabinet is used for a system requiring a battery rated above 17 Ah. The BC-1(R) consists of a surface mount wall box and door. The cabinet can house up

Requirements And Specifications For Installation

Mar 8, 2025 · The distribution box should be installed in an area close to the power supply to reduce power loss and ensure safety. Avoid installing in a

6 FAQs about [Can the distribution box be installed in the battery cabinet ]

What is a distribution box & DB panel?

With features like residual current circuit breakers and surge protection devices installed within its cabinet, a distribution board (DB box or DB panel) covers every aspect of electrical safety. It updates the number of circuits as needed, allowing for flexibility in case of wiring expansions or modifications. What are the distribution box types?

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

How does a power distribution box (DB box) work?

How does a power distribution box (DB box) works? A power distribution box (DB box) works by serving as a central electrical panel where electrical power is received and distributed from one input source to multiple output sources. This distribution box ensures the safe distribution of power throughout a building or area.

Where is the UPS battery cabinet located?

The battery cabinet may be located to either the left or right of the UPS cabinet. The recommended location is to the left of the UPS cabinet. This procedure assumes the battery cabinet is located to the left of the UPS cabinet. Figure 3‐2. UPS with Line-up-and-Match IBC-S

What is a power distribution box?

This distribution box ensures the safe distribution of power throughout a building or area. Through its design and functionality, as highlighted in this article, it plays a crucial role in the management and control of electrical systems.

How do I install a battery cabinet?

Create an installation plan for the battery cabinet (Chapter 2). Prepare your site for the battery cabinet (Chapter 2). Inspect and unpack the battery cabinet (Chapter 2). Unload and install the battery cabinet, and wire the system (Chapter 3). Complete the Installation Checklist (Chapter 3).

Learn More

- Is the battery cabinet a distribution box

- How big a battery cabinet can be placed in the center box

- Battery cabinet battery wind power box base station

- Energy storage battery cabinet into the box

- Distribution box energy storage battery

- Distribution cabinet cable container base station

- How to make a UPS battery cabinet

- UPS battery cabinet battery quantity

- A type C type battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.