Distribution Boxes Explained: Types, Functions, and Essential

Jun 3, 2025 · What is the distribution box? A distribution box—often referred to as a distribution panel or board—is a cabinet that houses electrical parts responsible for delivering electricity to

Detailed explanation of the difference between distribution

Oct 31, 2016 · 配电柜是配电箱的上一级配电设备,其体积较大,其中可以放入较大的电气设备,所以一般作为中等容量负荷的配电设备,包括了配电箱、电动机等,其适用容量在各个工艺

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Is the battery cabinet an electrical box

A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the batteryand all its accessories from the external environment. The enclosures come in different

6 Cell Battery Charging Locker Cabinet Distribution Box for

Aug 14, 2025 · This battery cabinet features a dual-layer hollow steel construction with fire and explosion resistance. It is equipped with a three-point linkage key lock that ensures the door

Power Distribution Box: Car Electricity Simplified

May 5, 2025 · A power distribution box is a car accessory that simplifies electricity distribution and management. It offers a convenient, safe, and efficient way to

What is the difference between distribution box, power box,

Distribution box: According to the requirements of electrical wiring, the switchgear, measuring instrument, protective device and auxiliary equipment are assembled in the closed or semi

Distribution Box: Streamlining Electrical Systems

Sep 15, 2024 · A distribution box, also known as a breaker box, houses circuit breakers or fuses for electrical distribution. It ensures safe and efficient power

Installation specification for UPS battery cabinets and racks

Aug 7, 2024 · Introduction to UPS battery cabinet and battery rack The UPS battery cabinet can safely and beautifully fit batteries inside, and it can also save space. The distribution cabinet

A Definitive Guide To Distribution Boxes

Mar 15, 2023 · The distribution box acts as the center of power distribution, distributing electricity to all connected devices. A distribution box, also known as a distribution board, panel board,

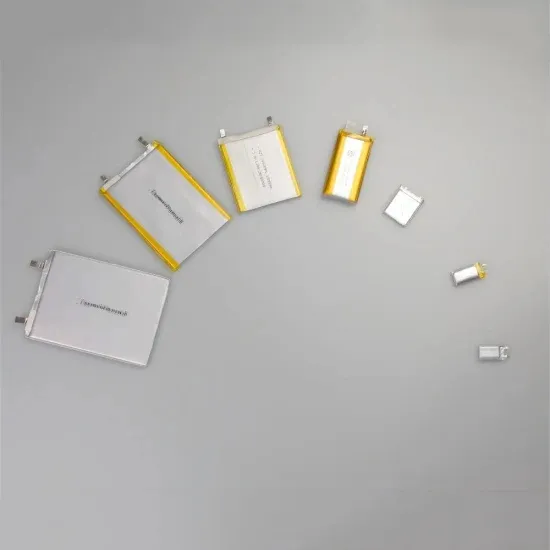

Battery Cabinets & Boxes

Jul 4, 2025 · Keep your backup energy storage systems running smoothly and safely with our durable battery boxes and cabinets. Storing and charging any type of battery in a dedicated

DC power supply cabinet working principle and

Oct 28, 2024 · The product consists of AC power supply, rectifier, charger, battery pack, DC distribution system, circuit breaker, charger, battery, circuit breaker

JXF Power Distribution Box (Cabinet) User Manual

Jan 4, 2023 · Installation Diagram Open-mounted distribution box installation method: Assemble four bolts into the four holes on the corners and tighten them into the expansion pipes to fix the

The Role Of The Distribution Box And Its Advantages in

Jul 2, 2024 · The distribution box or distribution cabinet assembles switchgear, measuring instruments, protective electrical appliances, and auxiliary equipment in a closed or semi

Is the battery cabinet an electrical box

Is the battery cabinet an electrical box Even with regular maintenance, electrical cabinets may encounter issues. Here are some common problems and their solutions: Electrical Cabinet

A Definitive Guide To Distribution Boxes

Sep 2, 2021 · The distribution box acts as the center of power distribution, distributing electricity to all connected devices. A distribution box, also known as a distribution board, panel board,

6 FAQs about [Is the battery cabinet a distribution box ]

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

What is a distribution box?

So, stay in touch! “A distribution box, also called a distribution panel or board, is a cabinet that contains electrical components used for the delivery of electricity to several circuits of a system.” This is essentially the area in which activities and specifically electricity distribution within a building are coordinated.

What should a battery cabinet have?

Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no movement). Cooling plates – some have cooling plates that help to control the enclosure temperature. Insulation system – insulation is also a safety measure a battery cabinet should have.

Do battery cabinet enclosures have a DIN rail?

Many enclosures have DIN rail. Electronic components –modern battery cabinet enclosures have sensors for smoke, shock, humidity, temperature, and moisture. These are safety measures to ensure the environment within the battery cabinet is safe. However, such enclosures are costlier.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

What rating should a battery cabinet have?

Indoor battery cabinet should have at least NEMA 1 rating. On the other hand, outdoor enclosures for batteries should have a NEMA 3R rating. It is important to note that the NEMA and IP rating varies depending on where you will install the enclosure. Indoor Battery Box Enclosure 2. Mounting Mechanism for Battery Cabinet

Learn More

- Can the distribution box be installed in the battery cabinet

- How to connect the signal base station battery to the power distribution cabinet

- Battery cabinet and electric box assembly ESS power base station said

- Battery cabinet distribution board base station

- Battery cabinet battery wind power box base station

- Battery cabinet connection box

- Afghanistan site energy battery cabinet distribution point

- Energy storage cabinet battery box base station and price

- How big a battery cabinet can be placed in the center box

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.