Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

Design and Verification Methodologies for Smart Battery

Feb 10, 2021 · Abstract—Lithium-Ion (Li-Ion) battery packs are continuously gaining in importance in many energy storage applications such as electric vehicles and smart energy grids. Such

Key Design Principles for Battery Pack Structures in Energy

Nov 25, 2024 · Designing battery packs for energy storage systems requires a comprehensive approach that integrates structural integrity, environmental adaptability, and safety

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The paper aims to investigate what has been achieved in the last twenty years to understand current and future trends when designing battery packs. The goal is to analyze the

GS2047FH intelligent lithium battery pack (planning)

GS2047FH intelligent lithium battery pack (planning) Features: Meet IEC62133 / un38 3 certification Standard SMBus v1 1 interface Integrated LED power status (SOC) indicator

Online battery purchase

1 day ago · I usually buy a large box, maybe 80 batteries (size 312). Since I only use one aid, that 80-pack lasts a long time. I need to re-order, butI can''t remember where I bought them the

(PDF) Mechanical Design of Battery Pack

International Journal of Engineering, 2019 Battery pack is one of the most important powertrain components in Electric Vehicles (EV). The performance of battery pack directly affects

Approach to Validation Plan Development for Advanced Battery Systems

Apr 12, 2011 · The validation plan for the Chevrolet Volt Rechargeable_Energy Storage System (RESS), the first lithium-ion battery pack designed and manufactured by General Motors (GM),

Demand planning of electric vehicle battery pack under battery

The electric vehicles (EV) battery pack quantity planning under the mode of centralized charging and unified distribution is researched. According to the differences between original usable

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The target concerns electric and hybrid vehicles and energy storage systems in general. The paper makes an original classification of past works defining seven levels of

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

BMS Planner for Custom Battery Packs

Aug 5, 2025 · Pack information Enter information on your planned pack in order to calculate what specific kind of BMS (battery management system) you''re going to need for your planned

Battery Pack Design Considerations for Performance and

1 day ago · How do you plan for controlling thermals in the battery enclosure? Can Epec certify battery packs for other customers or companies? Do all battery packs need a BMS to control

BATTERY CELL, MODULE & PACK TESTING

May 26, 2022 · A fully-equipped independent battery testing laboratory can help. You''ll reach the market faster with an instant expansion to test capacity and a broad menu of testing

Technical specifications and test protocols for the battery

Mar 29, 2021 · Section 3 lays out the testing plan to be applied to the final demonstrators of 3beLiEVe project at cell, module and pack level, in order to ensure the technical requirements,

6 FAQs about [Battery pack plan]

What is battery pack design?

Battery pack design is the foundation of the battery technology development workflow. The battery pack must provide the energy requirements of your system, and the pack architecture will inform the design and implementation of the battery management system and the thermal management system.

How to design a battery pack for electric vehicles?

When you think about designing a battery pack for electric vehicles you think at cell, module, BMS and pack level. However, you need to also rapidly think in terms of: electrical, thermal, mechanical, control and safety. Looking at the problem from different angles will help to ensure you don’t miss a critical element.

How do software tools help a battery pack design engineer?

Software tools enable battery pack design engineers to perform design space exploration and analyze design tradeoffs. The use of simulation models of battery packs helps engineers evaluate simulation performance and select the appropriate level of model fidelity for subsequent battery management and thermal management system design.

What is the first step in battery pack design?

The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process. During this stage, our engineering team works closely with clients to determine key parameters based on the specific application needs.

What are the parts of a battery pack?

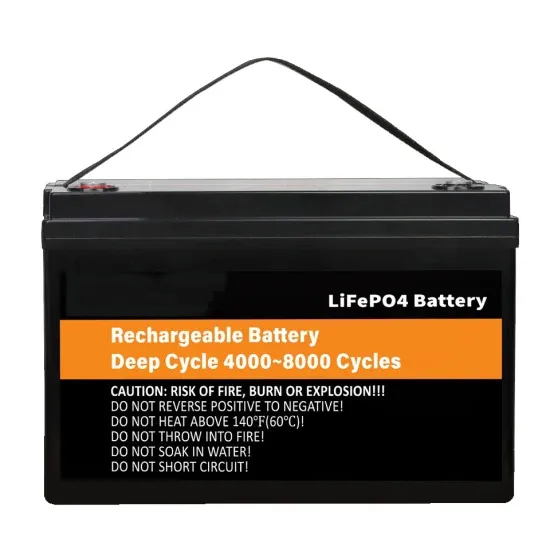

A battery pack consists of several interconnected parts, each playing a vital role in energy storage and power delivery: Battery Cells – The core energy storage units. Battery Management System (BMS) – Regulates voltage, temperature, and safety. Cooling System – Prevents overheating and maintains efficiency.

What is liquid cooled battery pack design?

Liquid-cooled battery pack design is increasingly requiring a design study that integrates energy consumption and efficiency, without omitting an assessment of weight and safety hazards.

Learn More

- Battery pack factory construction plan

- Pack processed battery

- 72v70A lithium battery pack

- Madrid lithium battery pack company

- What equipment does the cabinet battery pack factory need

- Bucharest large capacity lithium battery pack

- Islamabad 12v lithium battery pack

- How many cells are there in a battery pack for a railway base station

- Uganda lithium battery pack 72v assembly

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

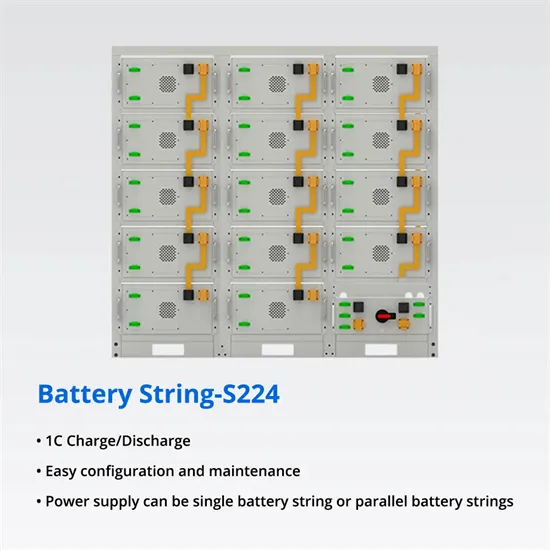

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.