Design of Battery Packs: Strategies for High Energy Density

Oct 4, 2019 · For this purpose, the newly developed battery pack with 100 kWh was installed in the vehicle, which initially used a standard 32-kWh battery, and since spring 2019 a 42-kWh

WO/2023/090830 MOVABLE BATTERY PACK PROCESSING

The present invention relates to a movable battery pack processing device comprising: a first container to which a discharging module or a cooling module is mounted; and a second

Thermal analysis and optimization of an EV battery pack for

Dec 1, 2020 · Battery packs are extensively used in electrical vehicles (EV) to avoid environmental pollution. The safety, aging and life of battery pack are significantly related to its

[电池扫盲]一文带小白了解电芯(cell),电池模块

Jun 18, 2023 · 电池包 将多个电池模块进行串并联,再加上用来管理电池温度或电压等的 电池管理系统 (BMS, Battery Management System)和冷却设备等,就

A multi-objective robust optimization model to

Apr 1, 2025 · In contrast, high fixed costs of remanufacturing centers result in constructing a limited number of battery pack production centers. Furthermore, recycling and battery pack

储能电池PACK:定义、组成、技术参数等技术核心

Feb 9, 2024 · 01 定义 锂离子电池PACK又称电池模组,是一种锂离子电池的制作工艺,是包装、封装、装配的意思,是指将多个锂离子单体电芯组通过并串联

Simplified Battery Pack Modeling Considering Inconsistency

Jul 31, 2020 · With the development of battery technology, large-scale battery applications are increasing. In order to obtain a higher current and voltage level and improve the overall energy

电池模组Pack生产线,技术原理、核心流程与前景展

Dec 14, 2024 · 电池模组 (Battery Module)通常由若干单体电池 (Cell)通过一定的连接方式组合而成,继而组装成更高层级的电池包 (Battery Pack),并最终应用

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

锂电池单体(cell)、电池组(Batteries)和电池包(pack

Jun 27, 2018 · 没有接触过锂电池的很多朋友,一般会把电池厂家生产好了的电池包(pack)当成是一块大电池,实际上,我们用的锂电池其实也跟铅酸电池一样,也是由一块一块的单体电池

Sorting and grouping optimization method for second-use

Dec 1, 2021 · The inconsistency of temperature leads to differences in cell aging speed and internal resistance in battery pack, which shortens the service life of the battery pack.

This EV battery fully recharges in just 18 seconds

Jun 16, 2025 · The British VarEVolt battery has been granted the certification needed so it can be manufactured on a large scale, meaning more EV makers

储能锂电池PACK生产制造工艺流程,锂电池PACK流程

Sep 20, 2024 · 储能锂电池组 PACK(即电池包)的制造流程涉及到多个步骤,从原材料的选择到最终产品的组装测试,每一步都需要严格的质量控制以确保产

Battery Pack Manufacturing Process

Mar 15, 2025 · In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and future innovations. Whether you''re a

Cost–benefit analysis for the recycling business case related

Download scientific diagram | Cost–benefit analysis for the recycling business case related to a processed battery pack using (a) NMC cathodes and (b) LFP cathodes (non-scaled state-of

Why are new energy vehicle battery shells processed with

Industry practice and technology extension Tesla 4680 battery structure: 6061 aluminum round bars are processed into an integrated battery tray, and the battery and the body are integrated

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

解剖储能电池PACK

Mar 15, 2024 · 1 电池Pack是什么?锂离子电池PACK又称电池模组,是一种锂离子电池的制作工艺,指将多个锂离子单体电芯组通过并串联的方式连接而成,

A cradle-to-grave life-cycle-assessment of dry-processed Li

Jan 1, 2025 · Results indicate that the dry-processed battery pack has advantages in both energy consumption and environmental impacts. The primary energy of the dry-processed EV battery

Understanding materials failure mechanisms for the

Mar 20, 2025 · Recent developments in recycling mechanisms have highlighted the importance of understanding battery failure mechanisms to achieve environmentally friendly and sustainable

This EV Battery Charges in 18 Seconds and It''s

Jun 16, 2025 · This EV Battery Charges in 18 Seconds and It''s Already Street Legal RML''s VarEVolt battery is blazing a trail for ultra-fast EV charging and

动力电池包pack组装全过程解析!

1 day ago · 高压线束可以看作是电池PACK的"大动脉血管",将动力电池系统心脏的动力不断输送到各个需要的部件中,低压线束则可以看作电池PACK的"神

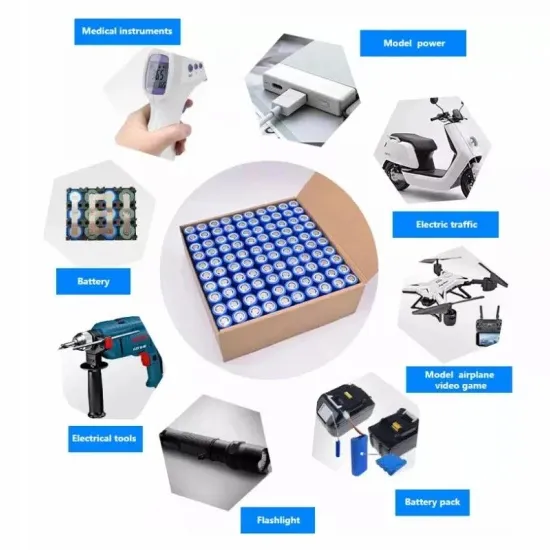

6 FAQs about [Pack processed battery]

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is battery pack assembly process?

Battery Pack Assembly Process Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

What is battery cell manufacturing process?

The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs. It consists of three major stages: electrode manufacturing, cell assembly, and cell finishing. Each step plays a crucial role in determining the battery’s performance and reliability. 1.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is a lithium-ion battery module & pack production line?

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

Learn More

- Minimum allowable voltage of lithium iron phosphate battery pack

- Energy storage battery pack for commercial use

- 20Ah lithium battery pack

- Do you have a 14 volt lithium battery pack

- 60kwh lithium iron phosphate battery pack price

- Belarus Gomel Energy Storage Battery Pack Factory

- Huawei Croatia power battery pack

- 20v lithium battery pack

- Lithium battery pack voltage-balanced adjustable power supply

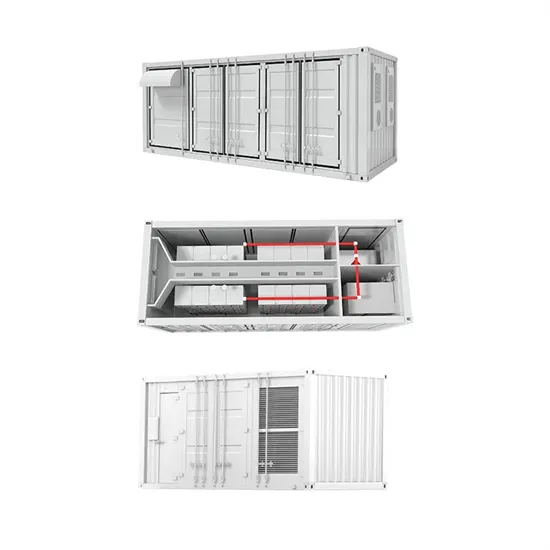

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.