Energy storage solutions for railway and metro systems

High energy density and superb performance with HOPPECKE lithium-ion batteries for the rail sector HOPPECKE''s lithium-ion battery systems feature a modular design consisting of 24-V

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · Battery cells are the smallest, fundamental unit of a battery system. They are responsible for electrochemical energy conversion, storing and releasing energy efficiently.

A Complete Guide to Understanding Battery Packs

Jul 24, 2024 · Battery packs come in many types, each suited to different needs and applications. Whether it''s for a smartphone, electric vehicle, or a portable

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · As electric cars become increasingly common in our daily lives, terms like "battery cell," "module," and "pack" pop up frequently. But what

How to calculate the lithium content in a battery

May 3, 2024 · When considering ''lithium content'', this does not necessarily mean how much lithium metal is in the battery. Technological advances have come up with new alloys to

Railway Batteries & Energy Systems for Metro, Subway and

Apr 1, 2023 · Hydrogen- and battery-based powertrains are evaluated on real trains. Numerical modelling and 3D CAD generation of each component are carried out. The layout of four

Introduction to Electric Vehicle Battery Modules and Packs

4 days ago · 12V battery packs for accessories 12V battery packs provide power to low energy accessories and applications in a vehicle, such as headlights and radio. How EV battery packs

Electric Vehicle Battery Components

1 day ago · The Nissan Leaf, for example, has 48 modules in its battery pack, with each module containing four cells. Thus, the Nissan Leaf has 192 EV battery cells with a 24 kWh capacity.

All you want to know about Electric Vehicle

Nov 27, 2018 · This large number along with the unstable nature of Lithium cells makes it difficult to design a Battery Pack for an Electric Car. In this article let

Research on improving the reliability and reducing the

Apr 25, 2024 · During the FSB operation, the number of series cells making up the battery module decreases by the same number as the cells bypassed by the relay, leading to a significant

6 FAQs about [How many cells are there in a battery pack for a railway base station]

What is a Li-ion battery pack?

At the base of every Li-ion battery pack is the battery cell or cells. A pack can contain one cell or many cells configured to achieve higher capacity or output voltage. This is achieved by connecting cells in parallel or series, and we’ll explore this much further in our next blog.

How many cells are in an electric vehicle battery?

An electric vehicle battery is often composed of many hundreds of small, individual cells arranged in a series/parallel configuration to achieve the desired voltage and capacity in the final pack. A common pack is composed of blocks of 18-30 parallel cells in series to achieve a desired voltage.

How many cells are in a Tesla battery pack?

Tesla's most popular battery pack contains 7,104 18650 cells in 16 444 cell modules. These battery packs can store up to 85 kWh of energy. In 2015, Panasonic altered the anode design, increasing the cell capacity by about 6%, enabling the battery packs to store up to 90 kWh of energy.

How much energy does a 400V pack produce?

A 400V pack would be arranged with 96 cells in series, 2 cells in parallel would create pack with a total energy of 34.6kWh Changing the number of cells in series by 1 gives a change in total energy of 3.6V x 2 x 50Ah = 360Wh. Increasing or decreasing the number of cells in parallel changes the total energy by 96 x 3.6V x 50Ah = 17,280Wh.

How much energy does a 96s30p pack produce?

If we select a very different cell, say a 5Ah cell, again with a nominal voltage of 3.6V we get a very different step size. Changing to a 5Ah cell you now need 20 of these connected in parallel to equal the capacity of two of the 50Ah cells connected in paralel. Hence, as shown a 96s30p pack configuration gives a total pack energy of 34.6kWh

What is the difference between a battery pack and a module?

Mechanical Support: Modules are housed in sturdy frames to provide structural integrity and protect cells from physical damage. A battery pack consists of multiple battery modules integrated to form a complete energy storage solution. Packs are engineered to deliver the required power and energy for specific applications.

Learn More

- How much does a communication base station battery cost

- Base station battery pack total voltage is too low alarm

- Base station battery pack model

- What is the voltage of the base station battery pack when fully charged

- How to connect the signal base station battery to the power distribution cabinet

- How big is the flow battery in a communication base station

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- How much does the Honiara base station battery cost

- How to connect the power supply battery of the communication base station

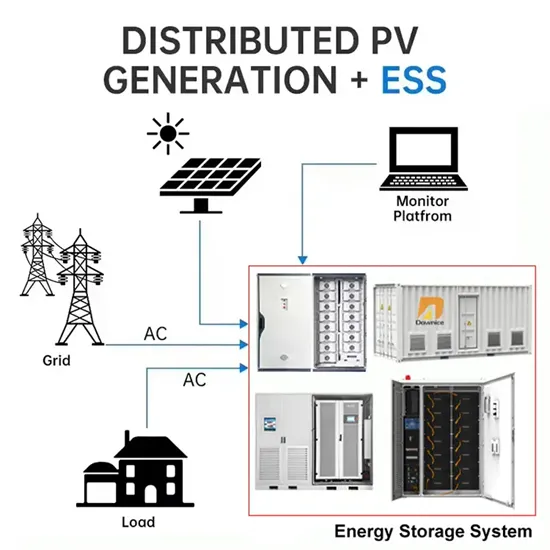

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.