Battery Pack – Taipu Technology

Feb 8, 2025 · Building a battery pack manufacturing factory is a strategic endeavor that requires meticulous planning, technical expertise, and a clear understanding of market demands.

Reliance to begin battery gigafactory operations

Aug 30, 2024 · RIL''s battery giga factory will manufacture battery chemicals, cells and packs. Reliance to begin battery gigafactory operations in 2026. 30 GWh

The Battery Cell Factory of the Future | BCG

Jan 30, 2025 · The Battery Cell Factory of the Future Offers Solutions The battery cell factory of the future addresses the challenges of cost optimization through

Tesla''s ''milestone'' Shanghai battery factory breaks ground

May 24, 2024 · Tesla''s plan to open a Megapack battery plant in Shanghai was announced In April 2023, cementing another foothold for the company in China. The land acquisition deal for

Inauguration of ACC''s First Gigafactory: A European Mega

May 30, 2023 · Inauguration of ACC''s first gigafactory: a European mega-project for battery production that should help accelerate the transition to a sustainable mobility accessible to all.

Fundamentals of Electric Vehicle Battery Pack Design

Dec 24, 2024 · Description This NOS unit is about preparing for the most discussed field of electric vehicles and the emerging trends in battery usage. This NOS unit is about designing

National Blueprint for Lithium Batteries 2021-2030

Jul 1, 2024 · Vision for the Lithium-Battery Supply Chain By 2030, the United States and its partners will establish a secure battery materials and technology supply chain that supports

Battery Cell Manufacturing and Gigafactories

Jun 10, 2024 · Battery Cell Manufacturing and Gigafactories Helping our clients build better batteries - Gigafactories designed for efficiency, quality, safety, and sustainability

Designing EV Battery Manufacturing Plants: A

Apr 23, 2025 · Discover the essential steps and considerations for designing efficient EV battery manufacturing plants. This guide covers site selection, layout optimization, and sustainable

6 FAQs about [Battery pack factory construction plan]

How does factory planning for battery production work?

You can get an insight into such a project in our whitepaper. In a three-step process, the interests of all parties involved in factory planning for battery production are first brought together. These areas of interest, such as planning for clean and dry rooms, lead to specific challenges in the planning process.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

Why do battery factories need a new way of thinking?

Battery factories require a new way of thinking about plant design and construction. Manufacturing engineers must pay careful attention to factors such as production flow, material handling, environmental control and fire safety.

What makes a good battery production facility?

Factories that mass-produce battery cells, modules and packs demand a different layout than traditional automotive facilities. For instance, they require multilevel mixing buildings that use gravity-fed production processes to transform raw materials into anodes and cathodes. Clean rooms are essential, and humidity control is extremely important.

How do you develop a custom battery?

The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support. Developing custom battery solutions requires extensive expertise across electrical, mechanical, and quality engineering.

What are the challenges of establishing an EV battery manufacturing facility?

In fact, there are four major challenges that go hand in hand with the complexities of establishing an EV battery manufacturing facility: Highly aggressive schedules. Multinational global teams. Budget and cost control. Unique quality issues. Battery factories require a new way of thinking about plant design and construction.

Learn More

- Dushanbe professional lithium battery pack factory price

- Albania Battery PACK Factory

- Battery pack factory in Mexico

- Gross profit of battery pack factory

- Energy storage battery factory construction time

- Albania lithium battery PACK factory

- Brazil lithium battery pack factory

- High quality wholesale battery and storage Factory

- Which company has the best quality of monitoring lithium battery pack

Industrial & Commercial Energy Storage Market Growth

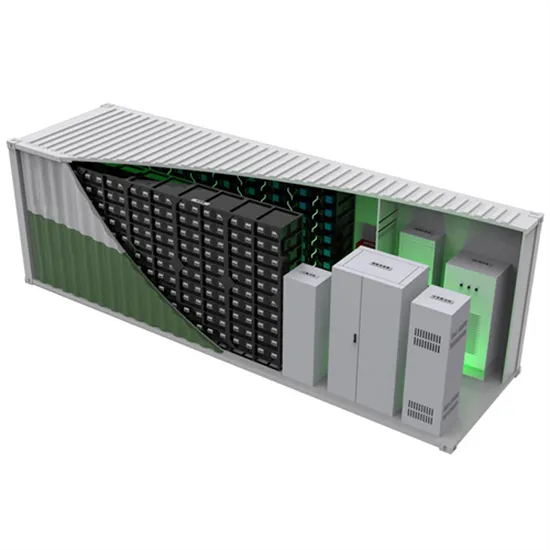

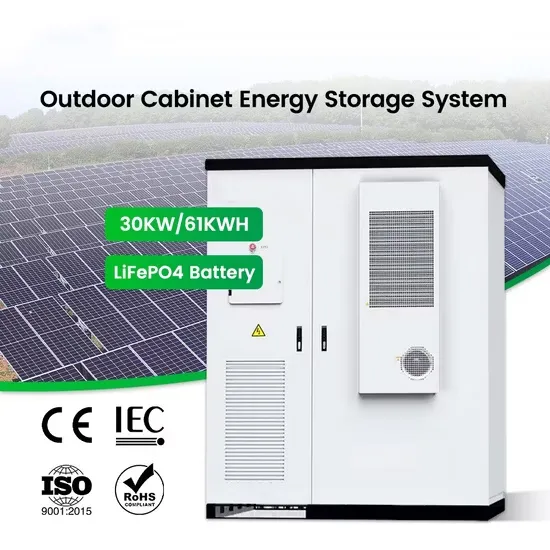

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.