energy storage charging pile battery

The battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage;

Photovoltaic-energy storage-integrated charging station

Jul 1, 2024 · The results provide a reference for policymakers and charging facility operators. In this study, an evaluation framework for retrofitting traditional electric vehicle charging stations

Types of EV Charging Pile_LiFe-Younger:Energy

Dec 12, 2023 · In contrast, charging piles with multiple charge points can service several vehicles at once, optimizing the usage and efficiency of the charging

Power Standards for New Energy Storage Charging Pile

The simulation results of this paper show that: (1) Enough output powercan be provided to meet the design and use requirements of the energy-storage charging pile; (2) the control guidance

Energy storage charging pile container size

Can energy storage battery be added on a traditional charging pile? For Android system, energy storage charging pile equipment adopts S5P4418 solution in hardware which manufactured by

Taipei sells energy storage charging piles

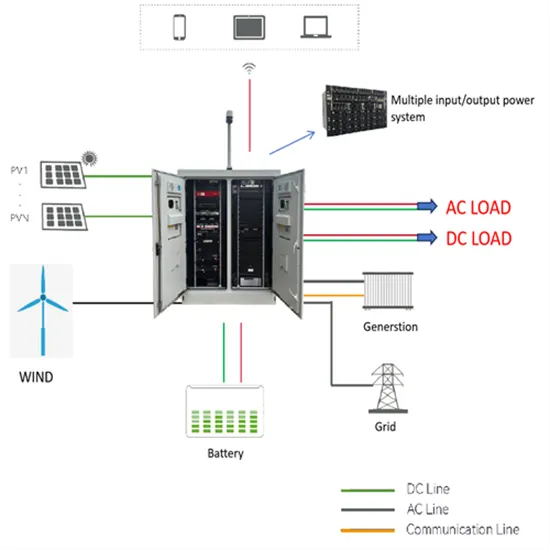

The charging pile energy storage system can be divided into four parts: the distribution network device, the charging system, the battery charging station and the real-time d it will double to

Several Chinese companies make energy storage charging piles

Does China''s e-commerce platform have a charging pile section? Data of China''s largest cross-board e-commerce platform, Alibaba, shows that in the first week of March 2023, overseas

Understanding Electric Vehicle Charging Piles: Common

Sep 13, 2024 · Common indicators and functional descriptions of electric vehicle charging piles [Simple principle Before explaining the various indicators, it is necessary to briefly understand

New energy storage charging pile first charge

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

Understanding the Charging Pile: The Future of

Feb 10, 2025 · What is a Charging Pile? An EV charger or charging pile is a unit intended for supplying electric energy to an electric vehicle that requires

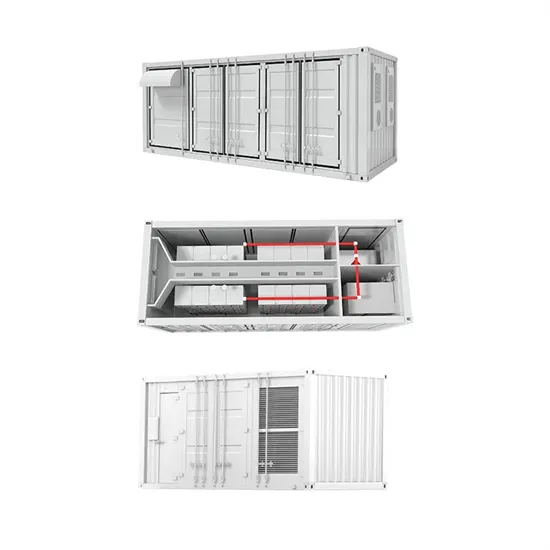

Technical characteristics of smart container charging pile

Next: Vanadium redox battery suitable for high power energy storage Technical characteristics of smart container charging pile.Power sharing: all power modules in the charging station are

Underground solar energy storage via energy piles: An

Jan 15, 2022 · Energy piles, which embed thermal loops into the pile body, have been used as heat exchangers in ground source heat pump systems to replace traditional boreholes.

Optimized operation strategy for energy storage charging piles

May 30, 2024 · In response to the issues arising from the disordered charging and discharging behavior of electric vehicle energy storage Charging piles, as well as

Energy Storage Charging Pile Management Based on

May 19, 2023 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

Charging Pile Energy Storage Box: The Game-Changer in EV

Ever wondered how fast-charging stations manage to power dozens of electric vehicles (EVs) without overloading the grid? The secret sauce lies in the charging pile energy storage box – a

Power Standards for New Energy Storage Charging Pile

Whatis the energy storage charging pile system for EV? The new energy storage charging pile system for EV is mainly composed of two parts: a power regulation systemand a charge and

Mobile charging: A novel charging system for electric vehicles

Nov 15, 2020 · The results show that, different from fixed charging, mobile charging helps the users save their time wasted in a charging station when their electric vehicles are being

Mobile container energy storage charging pile

Dahua Energy Technology Co., Ltd. is committed to the installation and service of new energy charging piles, distributed energy storage power stations, DC charging piles, integrated

Energy Storage Charging Pile Management Based on

Jan 16, 2024 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,...

Unlocking the Future: Understanding the EV Charging Pile

Jan 3, 2025 · Electric charging piles can be divided into three speeds: Level 1, Level 2, and DC fast charging. By building an effective network of charging stations, these piles positively

Energy Storage Charging Pile: The Game-Changer in EV Charging

Jul 21, 2024 · Meet the energy storage charging pile - the Swiss Army knife of EV infrastructure that''s quietly solving our biggest charging headaches. Unlike regular chargers, these smart

A deployment model of EV charging piles and its impact on

Nov 1, 2020 · The promotion effect of direct-current charging piles on EV sales is twice that of alternating-current charging piles in the one-year simulation of our model. Increasing the

Energy Storage Charging Pile Containers: The Future of EV Charging

Enter energy storage charging pile containers – the Swiss Army knives of EV infrastructure. These modular systems combine lithium-ion batteries, smart grid tech, and rapid chargers in

6 FAQs about [Energy storage container car charging pile]

Can battery energy storage technology be applied to EV charging piles?

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage; Multisim software is used to build an EV charging model in order to simulate the charge control guidance module.

What is energy storage charging pile equipment?

Design of Energy Storage Charging Pile Equipment The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period.

What is the function of the control device of energy storage charging pile?

The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period. In this section, the energy storage charging pile device is designed as a whole.

Why are EV charging piles important?

As electric vehicles become increasingly popular, the need for EV charging piles increases. They allow recharging of the batteries conveniently and effectively, hence supporting the use of electric vehicles (EVs) such as E-bikes, E-chariots, E-cars, and many more.

What is a charging pile?

The charging pile (as shown in Figure 1) is equivalent to a fuel tanker for a fuel car, which can provide power supply for an electric car.

What are electric vehicle charging pipes?

Electric Vehicle Charging Piles, also called electric vehicle charging stations, consist of electromechanical devices that provide electric energy to electric vehicles. They serve the same function as gas stations, except that they serve as power sources.

Learn More

- Zimbabwe Energy Storage Charging Pile

- Charging pile with energy storage

- Charging pile small energy storage power station

- Doha charging pile brand energy storage module

- Structure of energy storage charging pile

- Mozambique energy storage charging pile cost

- Electric Power Equipment Photovoltaic Energy Storage Charging Pile

- Vientiane photovoltaic energy storage integrated charging pile

- Is the energy storage cabinet charging pile assembled and installed

Industrial & Commercial Energy Storage Market Growth

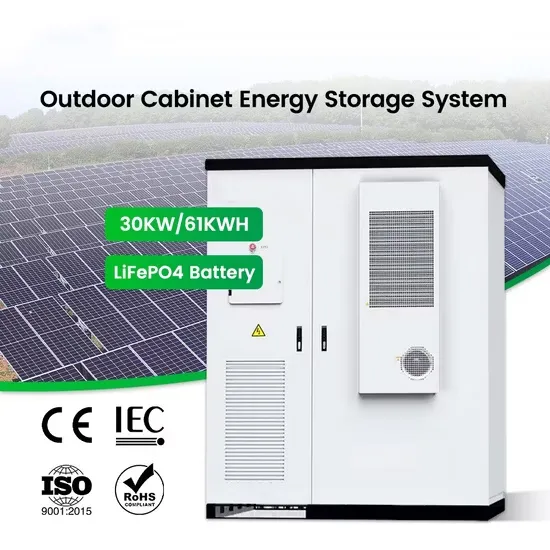

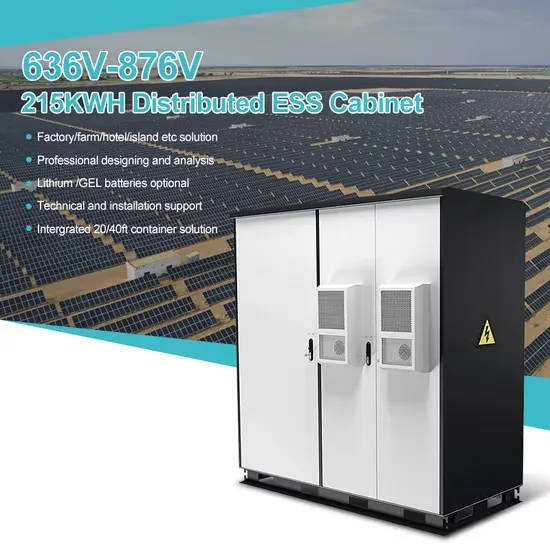

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.