photovoltaic energy storage charging pile application

A DC Charging Pile for New Energy Electric Vehicles This DC charging pile and its control technology provide some technical guarantee for the application of new energy electric

Energy storage charging pile assembly technical

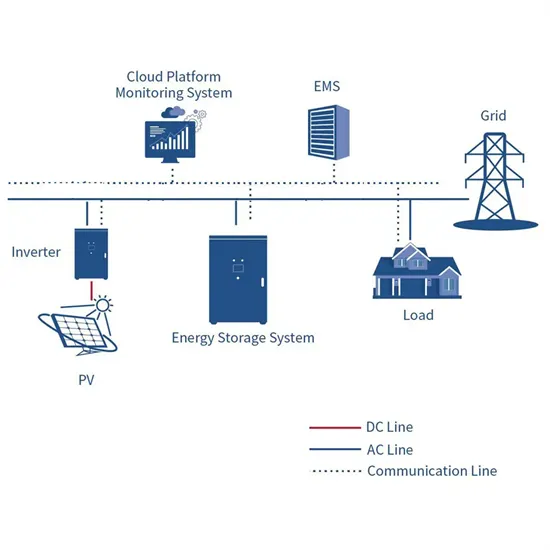

The battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage;

Can the energy storage charging pile be assembled

How a charging pile energy storage system can improve power supply and demand? Charging pile energy storage system can improve the relationship between power supply and demand.

What Do You Know About Charging Piles

Aug 16, 2025 · Standalone charging piles should be installed at least 2 meters away from buildings, fixed posts, trees, and other obstacles. The ground must be level to ensure a stable

How to tell if the energy storage charging pile is not

The charging pile is installed by professional technicians. Unauthorized installation changes cause safety accidents. If the loss is caused, the company will not bear any responsibility. 2

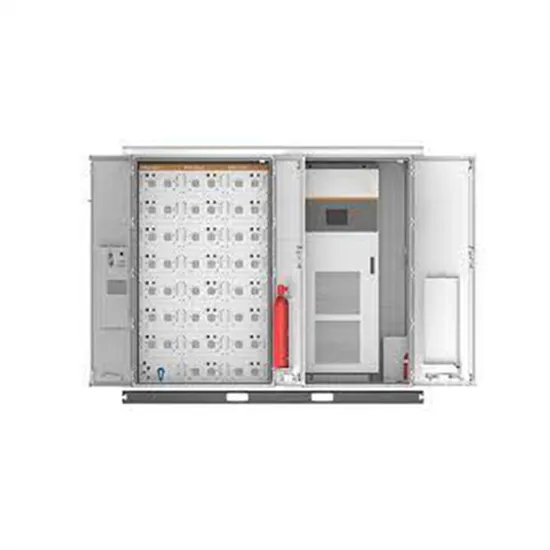

Energy Storage Charging Pile Containers: The Future of EV Charging

Enter energy storage charging pile containers – the Swiss Army knives of EV infrastructure. These modular systems combine lithium-ion batteries, smart grid tech, and rapid chargers in

Energy Storage Charging Pile Cabinet Installation

Proper implementation of energy storage charging pile cabinet installation specifications ensures system longevity and operational safety. As charging demands grow exponentially –

Charging Pile Energy Storage: Powering the Future of Electric

Oct 19, 2024 · The Grid''s New Best Friend: Energy Storage Meets EV Charging With global EV sales hitting 8.3 million units in 2024''s first three quarters alone [1], traditional charging

TECHNICAL REQUIREMENTS FOR ENERGY STORAGE CHARGING PILE

2022 Energy Storage Charging Pile Trend Chart Deployment of public charging infrastructure in anticipation of growth in EV sales is critical for widespread EV adoption. In Norway, for

EGS Smart Energy Storage Cabinet

3 days ago · As the world moves towards decarbonization, innovative energy storage solutions have become critical to meet our energy demands sustainably. AnyGap, established in 2015,

Liquid-cooled energy storage installed with new energy storage charging

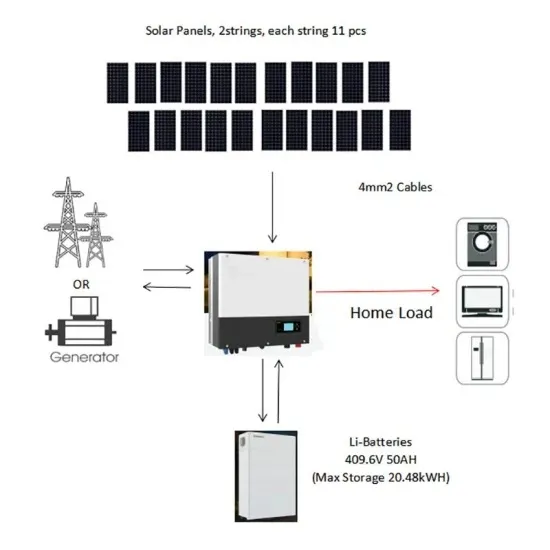

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,...

energy storage cabinet charging pile installation

TL;DR: In this paper, a mobile energy storage charging pile and a control method consisting of the steps that when the mobile ESS charging pile charges a vehicle through an energy storage

Energy Storage Smart Charging Pile Specifications: The

Sep 15, 2023 · With global EV sales hitting 10 million units in 2022, even your grandma might be Googling charging solutions. This article breaks down energy storage smart charging pile

Energy storage cabinet energy storage charging pile model

The experimental results show that this method can realize the dynamic load prediction of electric vehicle charging piles. When the number of stacking units is 11, the Smart photovoltaic

saracho

Such a huge charging pile gap, if built into a light storage charging station, will greatly improve the "electric vehicle long-distance travel", inter-city traffic "mileage anxiety"

Automatic energy storage charging pile installation

Automatic energy storage charging pile installation requirements What is the energy storage charging pile system for EV? The new energy storage charging pile system for EV is mainly

OVERVIEW 2025 THE 14TH SHANGHAI INTERNATIONAL CHARGING PILE

New high-energy storage charging pile Figure 7 shows the waveforms of a DC converter composed of one circuit. The reference current of each circuit is 25A, so the total charging

Energy storage charging pile cabinet installation drawings

Therefore, the invention aims to provide an artificial intelligence-based energy-saving charging pile and a control method, which can solve the problems in the prior art by burying a storage

Solar power cabinet charging pile installation tutorial

Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion batteries to advanced energy management systems, each

Energy Storage Charging Pile: The Game-Changer in EV Charging

Jul 21, 2024 · Why Your Next EV Charger Needs a Battery (Yes, Seriously) Ever waited in line for a charger only to find it''s out of service during peak hours? Meet the energy storage charging

Energy Storage and Hydrogen Charging Piles: The Dynamic

Nov 6, 2022 · The global energy storage market, already worth $33 billion [1], is now colliding with hydrogen infrastructure to create something revolutionary – the hydrogen charging pile

6 FAQs about [Is the energy storage cabinet charging pile assembled and installed ]

What is a charging pile cabinet?

The charging pile cabinet serves as the outer shell of the charging pile, protecting its internal structure and components. It is usually made from protective materials and features characteristics such as water resistance, dust resistance, and corrosion resistance, making it suitable for various harsh environmental conditions.

What are energy storage charging piles?

By balancing the electrical grid load, utilizing cost-effective electricity for storage, and supporting renewable energy integration, energy storage charging piles enhance grid stability, charging economics, and environmental performance.

Where should a charging pile be installed?

Standalone charging piles should be installed at least 2 meters away from buildings, fixed posts, trees, and other obstacles. The ground must be level to ensure a stable foundation. Before installation, a professional electrician should handle the wiring, and grounding protection should be considered.

What is an energy storage Charger?

An energy storage charger is an advanced device that integrates energy storage and charging functions. It can store electrical energy during low demand periods and provide charging services to electric vehicles during peak times.

How do EV charging piles work?

EV Charging Piles can adjust the voltage and current to charge various models of electric vehicles. Standalone charging piles should be installed at least 2 meters away from buildings, fixed posts, trees, and other obstacles. The ground must be level to ensure a stable foundation.

How to install a wall-mounted charging pile?

Wall-mounted charging piles require the wall to support the weight and vibrations of the equipment. The installation position should be chosen based on the wall’s quality and the height of the pile head. The wall material must be appropriate, and the ground should be level. Installation also requires a professional electrician for wiring.

Learn More

- Does the energy storage cabinet battery have an energy storage charging pile

- Canada Energy Storage Cabinet Energy Storage Charging Pile Sales

- Energy storage cabinet Energy storage Charging pile Photovoltaic

- Energy storage battery cabinet charging pile

- New Energy Charging Pile Energy Storage Cabinet

- Charging pile energy storage effect

- Paraguay energy storage charging pile customization

- Energy storage cabinet inverter graphene battery charging

- Berlin charging pile lithium battery storage cabinet recommendation

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.