Energy storage charging pile circuit structure

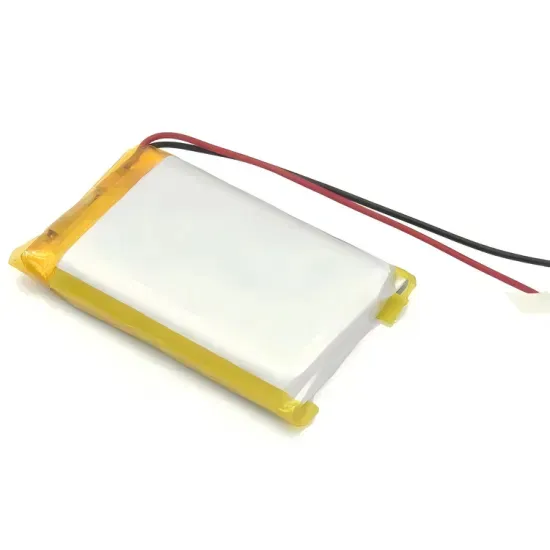

The battery fire accidents frequently occur during the storage and transportation of massive Lithium-ion batteries, posing a severe threat to the energy-storage system and public safety.

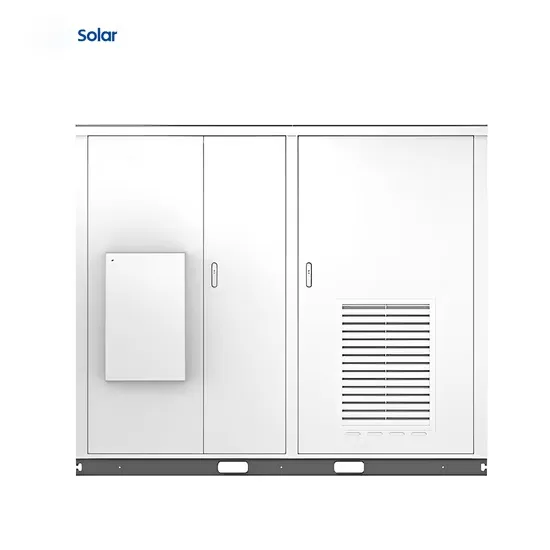

Automatic energy storage charging pile industry structure

Top 10 China EV Charging Pile Manufacturer In 2023 TELD New Energy Co., Ltd. is a prominent player in the domestic new energy vehicle charging industry, serving as both a manufacturer

EXPLANATION OF THE STRUCTURE DIAGRAM OF ENERGY STORAGE CHARGING PILE

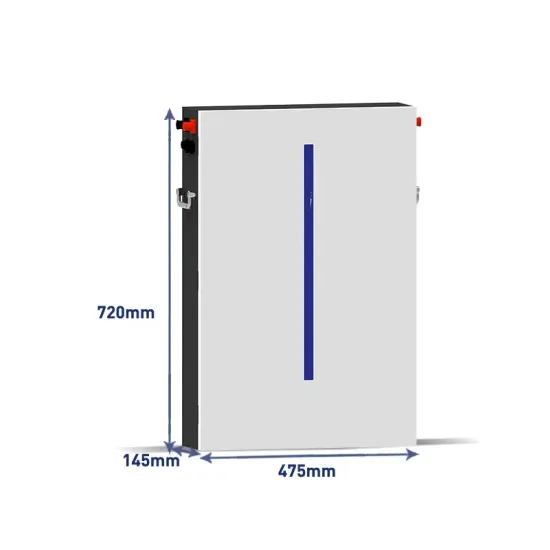

New Energy Storage Charging Pile Battery Bracket Figure 7 shows the waveforms of a DC converter composed of one circuit. The reference current of each circuit is 25A, so the total

Energy storage fast charging pile structure

energy storage system can manage energy costs and electrical loads while helping future-proof locations against costly grid upgrades. o DC Charging pile power has a trends to increase o

Energy storage charging pile status indication white sign

Charging pile play a pivotal role in the electric vehicle ecosystem, divided into two types: alternating current (AC) charging pile, known as "slow chargers," and direct current (DC)

Journal of Energy Storage

Sep 1, 2022 · A combined model of a fast-charging station and battery energy storage system (BESS) with superconducting magnetic energy storage is proposed in [159], which optimizes

The Design of Electric Vehicle Charging Pile Energy

Apr 27, 2017 · The structure diagram and control principle of the sys-tem are given. The electric vehicle charging pile can realize the fast charging of electric vehicles, and the battery of the

Energy Storage Charging Pile Management Based on

Jan 16, 2024 · The energy storage charging pile management system for EV is divided into three to modules: manage energy the storage whole charging process pile of equipment, charging.

Electric energy storage charging pile frame structure

a DC charging pile for new energy electric vehicles. The DC charging pile can expand the charging power through mult acts the charging experience and overall convenience. In this

Energy storage charging pile frame structure

Charging pile Charging pile; Portable Energy storage; UPS; Charging pile Charging piles are devices that provide electric energy for electric vehicles. They are usually installed in parking

How to improve the life of energy storage charging pile

Energy Efficiency in DC Fast Charging Power Conversion Technologies. Efficient DC charging piles rely on advanced power conversion technologies to minimize energy losses during fast

New energy storage charging pile composition structure

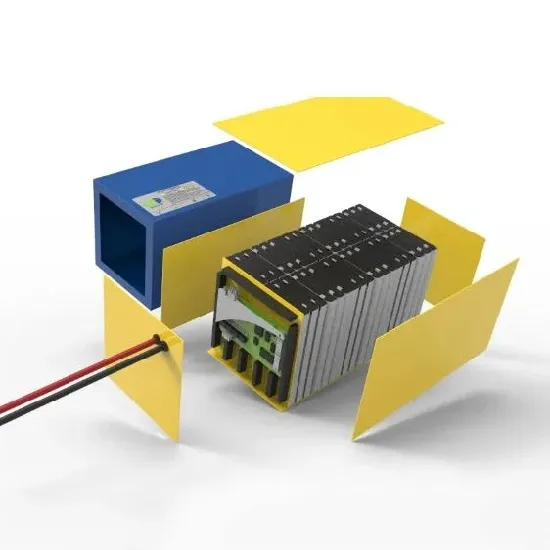

The new energy storage charging pile system for EV is mainly composed of two parts: a power regulation system and a charge and discharge control system. The power regulation system is

Energy storage charging pile structure diagram

The energy relationship between the SC of electric vehicles (EVs), the SC of centralized energy storage, and the PV power generation is constructed to solve for the upward SC and

Energy storage charging pile module structure

Can battery energy storage technology be applied to EV charging piles? In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to

Energy control of energy storage charging pile

Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy storage technology to the Under the &

Optimized operation strategy for energy storage charging piles

May 30, 2024 · In response to the issues arising from the disordered charging and discharging behavior of electric vehicle energy storage Charging piles, as well as the dynamic

Structural design of energy storage charging pile

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

Charging pile and energy storage ratio

Can battery energy storage technology be applied to EV charging piles? In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to

A DC Charging Pile for New Energy Electric Vehicles

Apr 24, 2023 · Abstract New energy electric vehicles will become a rational choice to achieve clean energy alternatives in the transportation field, and the advantages of new energy electric

Shiqiang Energy Storage Charging Pile

In order to study the ability of microgrid to absorb renewable energy and stabilize peak and valley load, This paper considers the operation modes of wind power, photovoltaic power, building

Energy Storage Charging Pile Management Based on

May 19, 2023 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

Optimized operation strategy for energy storage

May 30, 2024 · In response to the issues arising from the disordered charging and discharging behavior of electric vehicle energy storage Charging piles, as well

Structure comparison principle of energy storage

Can energy-storage charging piles meet the design and use requirements? The simulation results of this paper show that: (1) Enough output powercan be provided to meet the design and use

What are the structural requirements for energy storage

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,...

Structure of electric energy storage charging pile

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

Benefit allocation model of distributed photovoltaic power

Aug 1, 2020 · Abstract In this study, to develop a benefit-allocation model, in-depth analysis of a distributed photovoltaic-power-generation carport and energy-storage charging-pile project

New energy storage charging pile structure

What is energy storage charging pile management system? Based on the Internet of Things technology, the energy storage charging pile management system is designed as a three-layer

6 FAQs about [Structure of energy storage charging pile]

Can battery energy storage technology be applied to EV charging piles?

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage; Multisim software is used to build an EV charging model in order to simulate the charge control guidance module.

What is energy storage charging pile equipment?

Design of Energy Storage Charging Pile Equipment The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period.

What is the function of the control device of energy storage charging pile?

The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period. In this section, the energy storage charging pile device is designed as a whole.

How does a charging pile work?

The charging pile determines whether the power supply interface is fully connected with the charging pile by detecting the voltage of the detection point. Multisim software was used to build an EV charging model, and the process of output and detection of control guidance signal were simulated and verified.

What are the charging pile instructions?

Instructions for Charging Pile-V1.3.0: Power Output Mode: Can be switched between intelligent mode and priority mode. In intelligent mode, the charging pile power is equally distributed between the two vehicle connectors.

Why is it important to maintain the charging pile?

The importance of maintaining charging piles lies in the fact that influences by the changeable environment and ageing inner parts can cause various faults. Regular examination and maintenance are necessary during both product storage and using processes.

Learn More

- Is the energy storage cabinet charging pile assembled and installed

- New Energy Charging Pile Energy Storage Cabinet

- How much does a set of energy storage charging pile cost

- Energy storage battery available charging pile

- Vientiane photovoltaic energy storage integrated charging pile

- Charging pile energy storage power supply

- Peak shaving energy storage charging pile integrated machine

- Which is better energy storage or charging pile

- Charging pile installation energy storage

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.