储能堆供电充电桩的研究 Research on Power Supply

Apr 6, 2023 · This paper proposes an energy storage pile power supply system for charging pile, which aims to optimize the use and management of the energy storage structure of charging

Iraq charging pile energy storage system

Iraq Microgrid System Energy Storage Charging Pile Vehicle to Grid Charging. Through V2G, bidirectional charging could be used for demand cost reduction and/or participation in utility

Energy Storage Technology Development Under the

Dec 17, 2020 · Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy storage technology to the charging

Energy Storage Charging Pile: The Game-Changer in EV Charging

Jul 21, 2024 · Meet the energy storage charging pile - the Swiss Army knife of EV infrastructure that''s quietly solving our biggest charging headaches. Unlike regular chargers, these smart

Introduction to charging piles and energy storage

this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and

Heat generation model of energy storage charging pile

In order to study the ability of microgrid to absorb renewable energy and stabilize peak and valley load, This paper considers the operation modes of wind power, photovoltaic power, building

储能堆供电充电桩的研究

Apr 6, 2023 · This paper proposes an energy storage pile power supply system for charging pile, which aims to optimize the use and manage-ment of the energy storage structure of charging

Benefit allocation model of distributed photovoltaic power

Aug 1, 2020 · Abstract In this study, to develop a benefit-allocation model, in-depth analysis of a distributed photovoltaic-power-generation carport and energy-storage charging-pile project

Current situation and expectations of energy storage

This paper puts forward the dynamic load prediction of charging piles of energy storage electric vehicles based on time and space constraints in the Internet of Things environment, which can

The difference between new energy DC charging

Dec 15, 2022 · AC charging pile, commonly known as "slow charging", is a power supply device installed outside the electric vehicle and connected to the AC

A DC Charging Pile for New Energy Electric Vehicles

Oct 16, 2023 · Abstract New energy electric vehicles will become a rational choice to achieve clean energy alternatives in the transportation field, and the advantages of new energy electric

Reasons for power shortage of exported energy storage

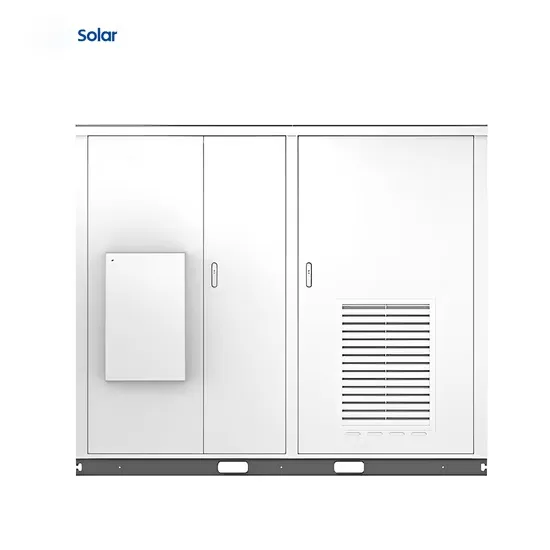

Energy storage charging piles combine photovoltaic power generation and energy storage systems, enabling self-generation and self-use of photovoltaic power, and storage of surplus

Photovoltaic-energy storage-integrated charging station

Jul 1, 2024 · The results provide a reference for policymakers and charging facility operators. In this study, an evaluation framework for retrofitting traditional electric vehicle charging stations

PRINCIPLE OF ENERGY STORAGE CHARGING PILE POWER SUPPLY

Can battery energy storage technology be applied to EV charging piles? In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to

(PDF) Research on energy storage charging piles based on

Feb 1, 2024 · Aiming at the charging demand of electric vehicles, an improved genetic algorithm is proposed to optimize the energy storage charging piles optimization scheme. Firstly, the

Why are energy storage charging piles cheaper

When needed, the energy storage battery supplies the power to charging piles. Solar energy, a clean energy, is delivered to the car''''s power battery using the PV and storage integrated

What charging pile is suitable for energy storage | NenPower

Jan 10, 2024 · 1. Various charging piles exist to suit different energy storage systems.2. Key considerations for selecting an appropriate charging pile include compatibility with battery

Energy Storage Charging Pile Management Based on

May 19, 2023 · The simulation results of this paper show that: (1) Enough output power can be provided to meet the design and use requirements of the energy-storage charging pile; (2) the

Research on Power Supply Charging Pile of

Jan 1, 2023 · 储能式充电桩是指在传统的充电桩箱内,按需要添加不同容量的储能电池。 由于在使 用充电桩进行充电. 电量,存在浪费时间等待后而充电桩单

Energy storage charging pile power supply interface type

Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy storage technology to the charging piles of

6 FAQs about [Charging pile energy storage power supply]

How a charging pile energy storage system can improve power supply and demand?

Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy storage technology to the charging piles of electric vehicles and optimizing them in conjunction with the power grid can achieve the effect of peak-shaving and valley-filling, which can effectively cut costs.

What is the energy storage charging pile system for EV?

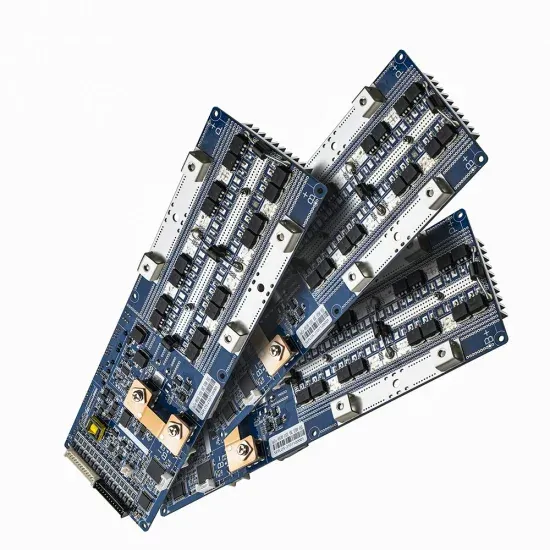

The new energy storage charging pile system for EV is mainly composed of two parts: a power regulation system and a charge and discharge control system. The power regulation system is the energy transmission link between the power grid, the energy storage battery pack, and the battery pack of the EV.

What is the function of the control device of energy storage charging pile?

The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period. In this section, the energy storage charging pile device is designed as a whole.

What are the parts of a charging pile energy storage system?

The charging pile energy storage system can be divided into four parts: the distribution network device, the charging system, the battery charging station and the real-time monitoring system [ 3 ].

What are electric vehicle charging piles?

Electric vehicle charging piles are different from traditional gas stations and are generally installed in public places. The wide deployment of charging pile energy storage systems is of great significance to the development of smart grids. Through the demand side management, the effect of stabilizing grid fluctuations can be achieved.

Can energy storage battery be added on a traditional charging pile?

For Android system, energy storage charging pile equipment adopts S5P4418 solution in hardware which manufactured by Shenzhen Youjian Hengtian Technology Co., Ltd., Shenzhen, China. In this paper, a high-performance energy storage battery is added on the basis of the traditional charging pile.

Learn More

- Electric Power Equipment Photovoltaic Energy Storage Charging Pile

- Charging pile small energy storage power station

- Customized smart energy storage power supply vehicle

- Riga lithium energy storage power supply sales price

- Battery Energy Storage Emergency Power Supply Vehicle

- Danish outdoor mobile energy storage power supply

- Abkhazia 380V energy storage power supply price

- Reykjavik lithium energy storage power supply

- Mobile energy storage power supply for engineering projects

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.