Zero-Carbon Service Area Scheme of Wind Power Solar

Aug 13, 2023 · First, according to the power consumption characteristics of the service area and the future power consumption trend, analyze the proportion of wind power storage and

Comprehensive benefits analysis of electric vehicle charging station

Jun 15, 2021 · The Photovoltaic–energy storage Charging Station (PV-ES CS) combines the construction of photovoltaic (PV) power generation, battery energy storage system (BESS)

Charging Pile Energy Storage: Powering the Future of Electric

Oct 19, 2024 · Imagine this: You''re at a highway rest stop, desperately needing a quick charge for your EV. But instead of waiting in line like it''s Black Friday at a Tesla Supercharger, you plug

How to connect the energy storage charging pile interface

The DC energy meter can read user information through the RS485 communication interface and monitor the charging status according to user needs. The energy detection software can

Energy Storage Charging Pile: The Game-Changer in EV Charging

Jul 21, 2024 · Meet the energy storage charging pile - the Swiss Army knife of EV infrastructure that''s quietly solving our biggest charging headaches. Unlike regular chargers, these smart

New EV Charging Stations, Electric Vehicle Grid Integration

6 days ago · The energy storage system stores electrical energy in the photovoltaic power station and then goes to the charging station to release the stored energy to the charging pile to

Optical Storage And Charging Integrated Microgrid Solution

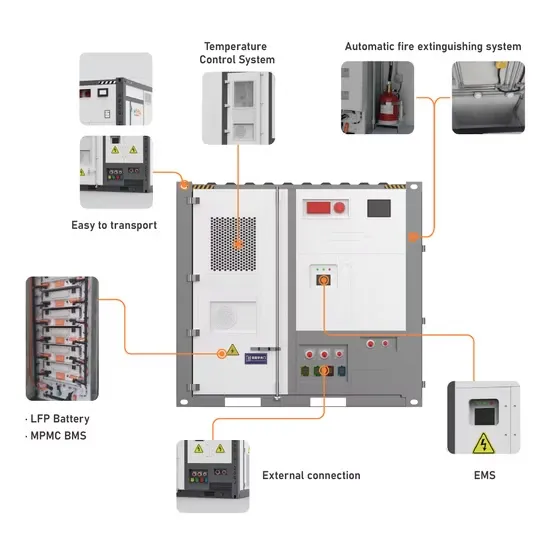

Product introduction: The Huijue''s Optical-storage-charging application scenario is a typical application of microgrid energy storage. The core consists of three parts – photovoltaic power

Optimized operation strategy for energy storage charging piles

May 30, 2024 · Based Eq. [1], to reduce the charging cost for users and charging piles, an effective charging and discharging load scheduling strategy is implemented by setting the

How to deal with a small energy storage charging pile

ing stations to accelerate transport electri c vehicle charging piles, and make full use of them . The photovoltai In this paper, we propose a dynamic energy management system (EMS) for a

How do charging piles solve the problem of energy storage?

Jun 26, 2024 · Charging piles offer innovative and effective solutions to energy storage challenges. 1. They facilitate efficient energy transfer from renewable sources, 2. They enable

photovoltaic energy storage charging pile application

The onboard battery as distributed energy storage and the centralized energy storage battery can contribute to the grid''''s demand response in the PV and storage integrated fast charging station.

Optimal operation of energy storage system in photovoltaic-storage

Nov 15, 2023 · Optimizing the energy storage charging and discharging strategy is conducive to improving the economy of the integrated operation of photovoltaic-storage charging. The

Design and Application of Smart EV Charging Piles

Jun 24, 2025 · From a design perspective, charging piles are classified into two primary categories based on power output: AC Charging Piles: Convert grid-supplied AC power to DC

Small Charging Pile Equipped with Energy Storage: The

If you''ve ever driven an electric vehicle (EV) and experienced "charge anxiety" – that sinking feeling when your battery hits 20% and the nearest station is 15 miles away – this article''s for

Small charging piles equipped with energy storage | C&I Energy Storage

Small Charging Pile Equipped with Energy Storage: The Future of EV Charging? If you''ve ever driven an electric vehicle (EV) and experienced "charge anxiety" – that sinking feeling when

Research on the capacity of charging stations based on

Aug 15, 2024 · • Provided is an operational model for charging stations for electric buses adopting a shared strategy • Adding energy storage facilities alleviates the power grid load and reduces

How to deal with a small energy storage charging pile

This paper proposes an energy storage pile power supply system for charging pile, which aims to optimize the use and manage-ment of the energy storage structure of charging pile and

Fire protection design of energy storage charging pile

Fire Protection for Electric Vehicles and Electric Vehicle Related Products. As for vehicles, It is a consumer products, there are many new energy consumer products, such as charging piles,

Energy Storage Smart Charging Pile Specifications: The

Sep 15, 2023 · The Nuts and Bolts of Smart Charging Modern smart charging piles aren''t just fancy power outlets. Take Delta Electronics'' latest model – it''s basically the Swiss Army knife

BATTERY ENERGY STORAGE SYSTEMS FOR CHARGING

The mtu Microgrid Controller enables seamless integration of generation from renewables, energy storage, participation in regional power markets, cloud connectivity (local and remote

A DC Charging Pile for New Energy Electric Vehicles

Oct 16, 2023 · Abstract New energy electric vehicles will become a rational choice to achieve clean energy alternatives in the transportation field, and the advantages of new energy electric

6 FAQs about [Charging pile small energy storage power station]

What is the difference between charging pile and charging stations?

1.Charging pile refers to a charging device with a charging gun and a human-machine interface, which is simply an electrical device that can be charged, either in one piece or in a split type.

What are the charging pile instructions?

Instructions for Charging Pile-V1.3.0: Power Output Mode: Can be switched between intelligent mode and priority mode. In intelligent mode, the charging pile power is equally distributed between the two vehicle connectors.

What is the installation distance of the charging pile?

The minimum installation distances for the charging pile are: no less than 700 mm from the back door to the wall, and no less than 500 mm from the side face to the wall. (5) The canopy is built together with the charging pile. (6) This installation method is just a sample for reference.

Can a charging station provide a high charging power of 22 kW?

the charging station cannot provide the high charging power of 22 kW. The charging station operator must decide whether to invest in gr e system.RESULTS OF THE USE CASECAPEX grid connection reinforcementGrid connection reinforcement means expanding the network from a low voltage (400 V) to a medium voltag

Do shaving charging stations have an intermittent energy load profile?

shaving Charging stations have an intermittent energy load profile. In many countries grid operators apply demand charges to commercial and industrial electricit consumers on the basis of their highest peak load per year or month. An mtu EnergyPack can help to cut charges by supplying energy in peak load hours and

How EV charging is affecting the power grid?

EV charging is putting enormous strain on the capacities of the grid. To prevent an overload at peak times, power availability, not distribution might be limited. By adding our mtu EnergyPack, ultra-fast chargin even on a low power grid connection. Integrate renewable energy mtu EnergyPa

Learn More

- Huawei Home Power Station Energy Storage Charging and Discharging Times

- Energy storage power station plus super fast charging

- Electric Power Equipment Photovoltaic Energy Storage Charging Pile

- Small charging station energy storage

- Power generation energy storage and charging power station

- Tirana Energy Storage Power Station Installation Project

- Is Rabat suitable for energy storage power station

- Wind energy storage power station solution

- Bridgetown Energy Storage Power Station Agent

Industrial & Commercial Energy Storage Market Growth

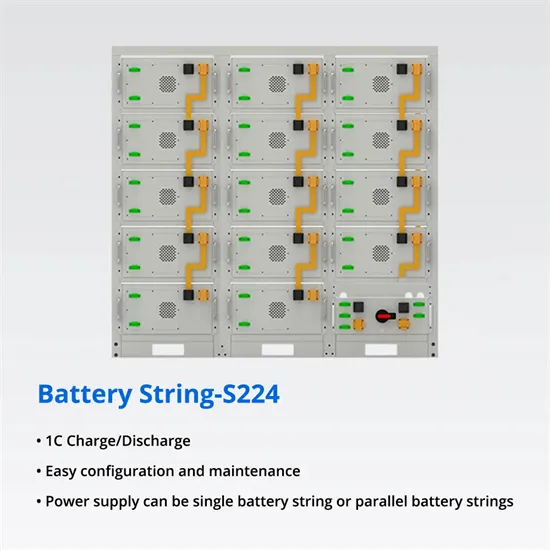

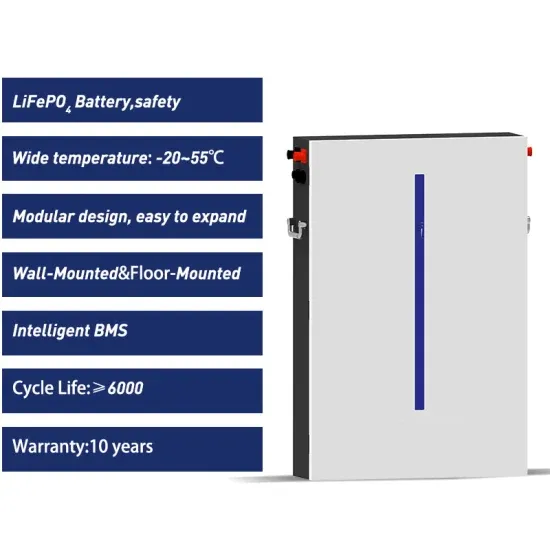

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.