What charging pile is suitable for energy storage | NenPower

Jan 10, 2024 · 1. Various charging piles exist to suit different energy storage systems.2. Key considerations for selecting an appropriate charging pile include compatibility with battery

photovoltaic energy storage charging pile application

Simultaneous capacity configuration and scheduling optimization of an integrated electrical vehicle charging station with photovoltaic and battery 1. Introduction The integrated electric

Energy Storage Charging Pile Management Based on

May 19, 2023 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

Energy Storage Charging Pile Containers: The Future of EV Charging

Enter energy storage charging pile containers – the Swiss Army knives of EV infrastructure. These modular systems combine lithium-ion batteries, smart grid tech, and rapid chargers in

Energy Storage Battery to Charging Pile: The Future of EV

Sep 10, 2019 · The Charging Station of 2030: Sneak Peek Solid-state batteries the size of suitcases powering ultra-fast 350kW chargers. Solar canopies feeding storage systems that

A DC Charging Pile for New Energy Electric Vehicles

Apr 24, 2023 · Abstract New energy electric vehicles will become a rational choice to achieve clean energy alternatives in the transportation field, and the advantages of new energy electric

A DC Charging Pile for New Energy Electric Vehicles

Oct 16, 2023 · Abstract New energy electric vehicles will become a rational choice to achieve clean energy alternatives in the transportation field, and the advantages of new energy electric

When will energy storage charging piles be available

Can battery energy storage technology be applied to EV charging piles? In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to

How do charging piles solve the problem of energy storage?

Jun 26, 2024 · One notable aspect of charging piles lies in their capability to interact with the electric grid and renewable energy resources. By capturing surplus energy generated during

Understanding the Charging Pile: The Future of

Feb 10, 2025 · What is a Charging Pile? An EV charger or charging pile is a unit intended for supplying electric energy to an electric vehicle that requires

CHARGING PILE – A MAJOR EV CHARGING METHOD

How many small batteries are there in an energy storage charging pile While the market for grid batteries is small compared to the other major form of grid storage, pumped hydroelectricity, it

BATTERY ENERGY STORAGE SYSTEMS FOR CHARGING

the infrastructure for the raising number of electric vehicles ( V). A connection to the electric power grid may be available, always with suficient capacity to support high power charging. Battery

Presentation title on multiple lines

Dec 14, 2020 · SiC based AC/DC Solution for Charging Station and Energy Storage Applications JIANG Tianyang Industrial Power & Energy Competence Center Region, STMicroelectronics

A holistic assessment of the photovoltaic-energy storage

Nov 15, 2023 · The Photovoltaic-energy storage-integrated Charging Station (PV-ES-I CS) is a facility that integrates PV power generation, battery storage, and EV charging capabilities (as

Sharing private charging piles to develop electric vehicle charging

Jul 15, 2025 · The increasing use of electric vehicles (EVs) has led to challenges in determining the most effective methods for charging their batteries. A potential solution to address this

Current situation and expectations of energy storage

this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

Ev charging piles energy storage battery

Varieties of Portable Charging Stations The market for ev charging piles energy storage battery is diverse, with several types available to meet different user needs and scenarios. Some

China energy storage building charging pile

Dahua Energy Technology Co., Ltd. is committed to the installation and service of new energy charging piles, distributed energy storage power stations, DC charging piles, integrated

Charging Pile Energy Storage: Powering the Future of Electric

Oct 19, 2024 · Welcome to the world of charging pile energy storage – where power meets pizzazz. Let''s dissect why this tech combo is hotter than a lithium battery in July....

Energy storage charging pile battery cell production

This provides excellent opportunities for the adoption of digitalization to address the challenges of gigascale battery cell production, not only because it can effectively manage the production

Optimizing bus charging infrastructure by incorporating

Feb 3, 2025 · Integrating solar photovoltaic (PV) and battery energy storage (BES) into bus charging infrastructure offers a feasible solution to the challenge of carbon emissions and grid

6 FAQs about [Energy storage battery available charging pile]

Can battery energy storage technology be applied to EV charging piles?

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage; Multisim software is used to build an EV charging model in order to simulate the charge control guidance module.

How a charging pile energy storage system can improve power supply and demand?

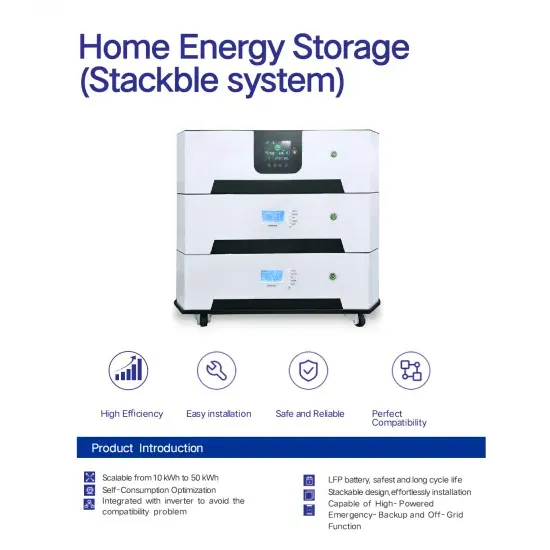

Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy storage technology to the charging piles of electric vehicles and optimizing them in conjunction with the power grid can achieve the effect of peak-shaving and valley-filling, which can effectively cut costs.

What are electric vehicle charging piles?

Electric vehicle charging piles are different from traditional gas stations and are generally installed in public places. The wide deployment of charging pile energy storage systems is of great significance to the development of smart grids. Through the demand side management, the effect of stabilizing grid fluctuations can be achieved.

What are the parts of a charging pile energy storage system?

The charging pile energy storage system can be divided into four parts: the distribution network device, the charging system, the battery charging station and the real-time monitoring system [ 3 ].

What is the function of the control device of energy storage charging pile?

The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period. In this section, the energy storage charging pile device is designed as a whole.

What is a charging pile?

The charging pile (as shown in Figure 1) is equivalent to a fuel tanker for a fuel car, which can provide power supply for an electric car.

Learn More

- Energy storage battery cabinet charging pile

- Does the energy storage cabinet battery have an energy storage charging pile

- Charging pile energy storage battery design standards

- Installation of energy storage battery charging pile

- Berlin charging pile lithium battery storage cabinet recommendation

- Canada Energy Storage Cabinet Energy Storage Charging Pile Sales

- Charging pile energy storage integrated

- Zimbabwe Energy Storage Charging Pile

- The role of the energy storage box in the Saint Lucia charging pile

Industrial & Commercial Energy Storage Market Growth

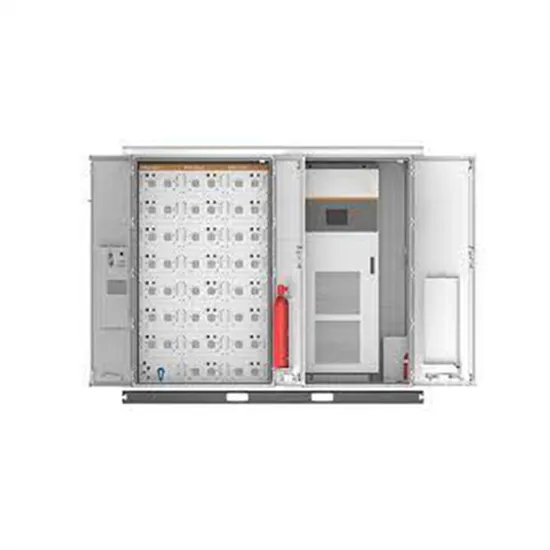

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.