EV Charging with Integrated Energy Storage

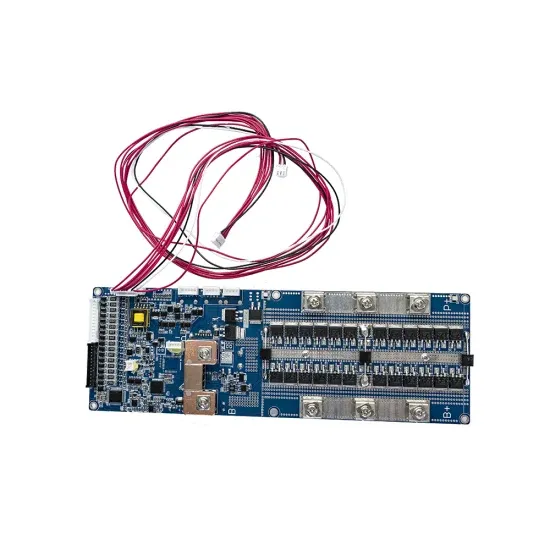

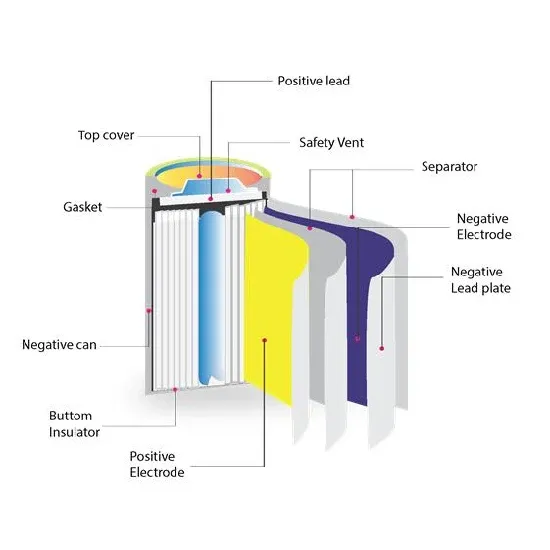

1. System composition The energy storage system of charging piles usually consists of the following key parts: Energy storage device: This is the core component of the system, which is

Energy storage integrated charging pile, Energy storage integrated

Energy storage integrated charging pile, find quality Energy storage integrated charging pile products,Energy storage integrated charging pile Manufacturers, Energy storage integrated

Capacity of medium hybrid energy storage charging pile

The hybrid energy storage configuration scheme is evaluated based on the annual comprehensive cost of the energy storage system(Lei et al. 2023). Based on balance control

Pathways for Coordinated Development of Photovoltaic

Mar 21, 2025 · This paper investigates how various patented innovations in PV storage-integrated devices, charging piles, and intelligent control cabinets can be synergized to create a more

A DC Charging Pile for New Energy Electric Vehicles

Apr 24, 2023 · Abstract New energy electric vehicles will become a rational choice to achieve clean energy alternatives in the transportation field, and the advantages of new energy electric

Energy Storage Charging Pile Management Based on

May 19, 2023 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

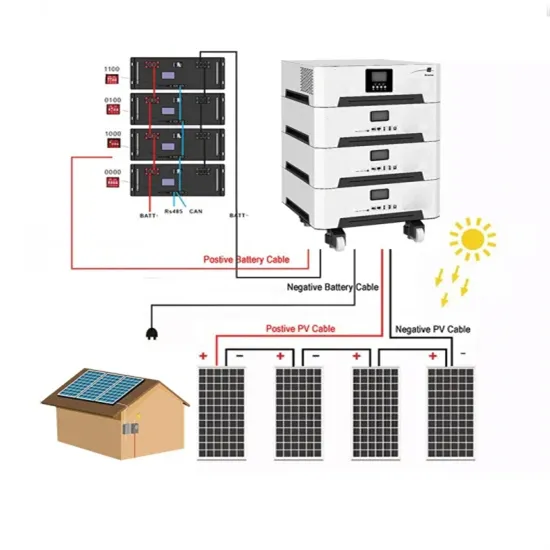

Optical Storage And Charging Integrated Microgrid Solution

Product introduction: The Huijue''s Optical-storage-charging application scenario is a typical application of microgrid energy storage. The core consists of three parts – photovoltaic power

How do charging piles solve the problem of energy storage?

Jun 26, 2024 · Charging piles offer innovative and effective solutions to energy storage challenges. 1. They facilitate efficient energy transfer from renewable sources, 2. They enable

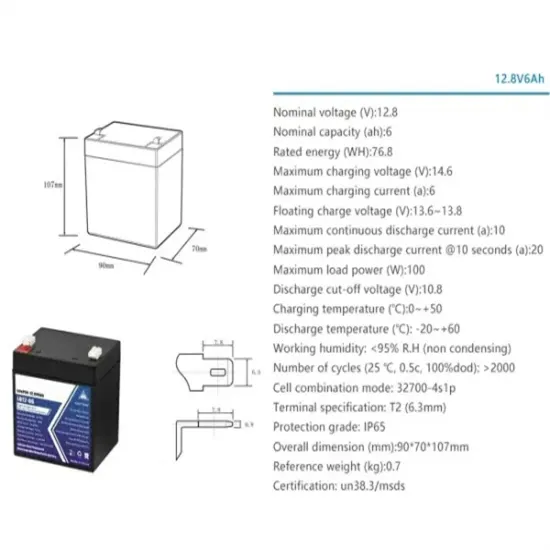

energy storage charging pile battery

The battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage;

Benefit allocation model of distributed photovoltaic power

Dec 4, 2021 · In this study, to develop a benefit-allocation model, in-depth analysis of a distributed photovoltaic-powergeneration carport and energy-storage charging-pile project was

Can energy storage charging piles be equipped with

Solar-and-energy storage-integrated charging stations typically encompass several essential components: solar panels,energy storage systems,inverters,and electric vehicle supply

光储充一体化充电站系统研究-【维普期刊官网】

This paper studies and discusses the basic composition of the optical storage and charging integrated power station system and the working principles of photovoltaic power generation

Energy Storage Charging Pile Management Based on

May 19, 2023 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,...

Benefit allocation model of distributed photovoltaic power

Jun 21, 2025 · In this study, to develop a benefit-allocation model, in-depth analysis of a distributed photovoltaic-powergeneration carport and energy-storage charging-pile project was

photovoltaic energy storage charging pile application

Simultaneous capacity configuration and scheduling optimization of an integrated electrical vehicle charging station with photovoltaic and battery 1. Introduction The integrated electric

Electric energy storage charging pile store opening

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

含电动汽车的光储充一体化电站设施规划与运行联合

Sep 14, 2021 · From the perspective of planning, make configuration decisions on photovoltaic capacity, energy storage capacity, the number of charging piles,

Photovoltaic-energy storage-integrated charging station

Jul 1, 2024 · The results provide a reference for policymakers and charging facility operators. In this study, an evaluation framework for retrofitting traditional electric vehicle charging stations

Inspur zero-carbon terminal

Jan 17, 2025 · Inspur zero-carbon terminal consists of charging piles, photovoltaic modules, inverters, energy storage battery cabinets and other new energy products, and can provide

Charging Pile Energy Storage: Powering the Future of Electric

Oct 19, 2024 · With global EV sales hitting 8.3 million units in 2024''s first three quarters alone [1], traditional charging methods are about as effective as using a garden hose to fill an Olympic

Dynamic load prediction of charging piles for energy storage

This paper puts forward the dynamic load prediction of charging piles of energy storage electric vehicles based on time and space constraints in the Internet of Things environment, which can

6 FAQs about [Charging pile energy storage integrated]

Can battery energy storage technology be applied to EV charging piles?

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage; Multisim software is used to build an EV charging model in order to simulate the charge control guidance module.

What is energy storage charging pile equipment?

Design of Energy Storage Charging Pile Equipment The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period.

What is the function of the control device of energy storage charging pile?

The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period. In this section, the energy storage charging pile device is designed as a whole.

Can energy-storage charging piles meet the design and use requirements?

The simulation results of this paper show that: (1) Enough output power can be provided to meet the design and use requirements of the energy-storage charging pile; (2) the control guidance circuit can meet the requirements of the charging pile; (3) during the switching process of charging pile connection state, the voltage state changes smoothly.

What is a charging pile management system?

The traditional charging pile management system usually only focuses on the basic charging function, which has problems such as single system function, poor user experience, and inconvenient management.

What is a charging pile?

The charging pile (as shown in Figure 1) is equivalent to a fuel tanker for a fuel car, which can provide power supply for an electric car.

Learn More

- Peak shaving energy storage charging pile integrated machine

- Installation of energy storage integrated charging pile in Kuwait

- Charging pile energy storage integrated

- Vientiane photovoltaic energy storage integrated charging pile

- Energy storage container car charging pile

- Structure of energy storage charging pile

- Charging pile with energy storage

- AC Energy Storage Charging Pile

- Charging pile energy storage battery design standards

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.