Tesla 18650, 2170 and 4680 Battery Cell Comparison Basics

May 18, 2021 · Twitter account Whole Mars Catalog recently posted an image of metal facsimiles of the 18650, 2170 and the new 4680 battery cells for powering Tesla''s latest models. The

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · Battery Pack Design of Cylindrical Lithium-Ion Cells and Modelling of Prismatic Lithium-Ion Battery Based on Characterization Tests By Ruiwen Chen, B.Eng. & Co-op.

Which is better, cylindrical lithium battery or soft pack lithium

Dec 5, 2024 · Taking the 18650 battery as an example, 18 represents the diameter of the battery, 65 represents the height of the battery, and 0 represents that it is a cylindrical battery.

Potentials of 46 mm cylindrical cells: On the way

Apr 11, 2023 · In the automotive industry, much is promised from the cell: High power density and fast charging capability, more efficient integration in the

Investigating the efficiency of a novel combined

Nov 25, 2023 · • A novel combined direct/indirect liquid-cooled thermal management system is proposed for advanced electric vehicles. • Numerical evaluation of the thermal efficiency of the

(PDF) Lithium-Ion Cells in Automotive Applications: Tesla

Dec 29, 2023 · Among the current battery technologies, lithium-ion batteries (LIBs) are essential in shaping future energy landscapes in stationary storage and e-mobility. Among all

rechargeable 46800 battery Xpower Lithium Battery

rechargeable 46800 battery Xpower''s lithium batteries offer unmatched reliability and efficiency for industrial energy storage and renewable energy systems. Designed for longevity and quick

Samsung INR46-series 46800 25Ah Li-Battery 250A

🔋 Samsung INR46‑series 46800 25Ah Li‑Battery (250 A) Elevate your high‑performance builds with the Samsung INR46-series cylindrical cell: a massive 25,000 mAh capacity battery

Investigating the efficiency of a novel combined

Nov 25, 2023 · Numerical evaluation of the thermal efficiency of the new 46800-format Lithium-ion battery pack is conducted. The novel separator mesh plates improve temperature uniformity in

46800 battery, the end of the era of fuel vehicles?-EEWORLD

Al l cells in the lithium battery pack are 360° coated with lightweight self-leveling thermal conductive adhesive." The thermal conductive adhesive can ensure that the temperature

Sds Lges46800 Lithium | PDF | Dangerous Goods | Firefighting

Jun 3, 2025 · The document provides a safety data sheet for lithium ion batteries manufactured by LG Energy Solution, detailing product information, safety certifications, and handling

6 FAQs about [46800 lithium battery pack]

Does the new 46800-format lithium-ion battery pack have thermal efficiency?

Numerical evaluation of the thermal efficiency of the new 46800-format Lithium-ion battery pack is conducted. The novel separator mesh plates improve temperature uniformity in the battery pack. The proposed BTMS can maintain the maximum temperature below 40 °C, even at an ambient temperature of 35 °C.

Is a 46800 Li-ion battery a good battery?

Although the 46800-type Li-ion batteries have superior attributes, including high driving range, energy density, and fast charging capability, it is plagued by higher heat generation during discharge impacting performance, efficiency, and lifespan.

Does a 46800-type battery pack have a cooling system?

To the best of the authors’ knowledge, the thermal performance of 46800-type battery pack with a cooling system has not been experimentally studied so far; therefore, the thermal performances of 46800-type battery and liquid cooling system are separately validated.

Does Cuo nanofluid increase heat generation rate of 46800-type Li-ion batteries?

Consequently, the heat generation rate of 46800-type Li-ion batteries is increased. Accordingly, the thermal behavior of LIBs indicated that the CuO nanofluid with any volume fraction in the proposed cooling system is sufficient for low C-rate (less than1C) discharge processes.

Can a 46800-type Lib pack handle a high heat generation rate?

In conclusion, even with a consistent coolant inlet temperature of 25 °C, effectively controlling and managing the high heat generation rate of the 46800-type LIB pack at an ambient temperature of 40 °C becomes challenging.

What is a lumped thermal model of a 46800-format LIB cell?

First, the lumped thermal model of 46800-format is evaluated and compared with Tranter et al. . They used a coupled electrochemical model and thermal properties for conventional tabbed design to predict the temperature of a 46800-type LIB cell under 1C discharge operation.

Learn More

- Is there lithium phosphorus lithium battery pack processing in Malta

- Which lithium battery pack is cheaper in New York USA

- What does lithium battery pack gram mean

- Bangji RV lithium battery pack

- Montevideo 12v lithium battery pack

- 72200 Lithium battery pack structure

- Peru ups power lithium battery pack

- Shallow charge and discharge of lithium battery pack

- 30a lithium battery pack

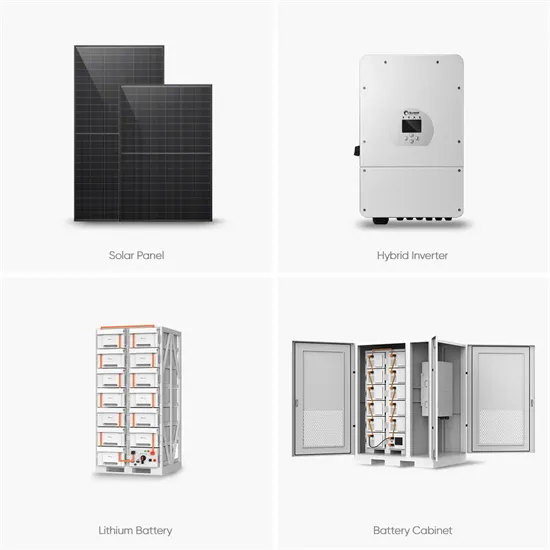

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.