Specifications and models of cabinets in weak current

A lithium ion battery cabinet is a specialized enclosure designed to house lithium-ion batteries. These cabinets are engineered to ensure the safe operation of battery

The ultimate retrofit for home weak current boxes

Aug 2, 2024 · Now there are larger cabinets, which are more compatible and can accommodate more devices. When choosing the cabinet, the iron plate material is selected to prevent

How to dismantle the weak current battery cabinet

When breaking down a lithium-ion battery pack, having the right tools for the job is critical. The tools you use to disassemble a lithium-ion battery pack can be the difference between

VRLA battery cabinets

3 days ago · - Designed according to the specific UPS model for easy connections, correct recharge current and appropriate discharge rating to optimize battery life. - Modular hot-swap

Battery cabinet installation in weak current room

Batteries exceeding charging power of 2 kW shall be installed in closed cabinets, containers or battery rooms forced ventilated to open deck area. Lead batteries up to 3 kW may be

How to choose a suitable weak current distribution cabinet?

The following are some suggestions: Determine the use requirements Load situation: Make clear the number, type and respective power of the equipment that needs to be connected to the

The function of battery cabinet in weak current room

BATTERY CABINETS CATALOGUE Being a real battery room, the cabinet has: 1) Adequate natural ventilation (in the charging conditions indicated by ENERPOWER). 2) Possible forced

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · 6.2.2 EQUIPMENT MOUNTING Do not attempt to unpack or move the battery cabinet without assistance. Use appropriate handling equipment rated to bear the weight and

480V, 3PH, UPS with 4 hours backup battery

Jun 14, 2018 · I need to design a high reliability power back up for 4x 20HP motors (480v, 3PH) each for a critical application. ATS with GEN is not an option. The client requested to design a

The function of battery cabinet in weak current room

UPS (Uninterruptible Power Supply) systems play a critical role in providing backup power to weak current equipment rooms, ensuring uninterrupted operation of essential systems.

Weak motor room cabinet positioning and wiring skills

Feb 21, 2022 · There are many weak motor cabinets, servers, patch panels, routers and other equipment in the computer room, and these devices are one link and one link between them,

The difference between weak current engineering and weak current

Feb 22, 2023 · Application in | Basic weak current engineering Distribution box, weak current box, telecommunication cabinet, optical fiber box, electrical box, hand hole. Application in | Use

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these,

How to use the weak current backup battery cabinet

• Verify that no current will flow when the battery is connected or disconnected by opening battery disconnects (if available) or adjusting the system to match battery voltage. • Risk

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Weak current engineering cabinet installation standard rules

May 20, 2024 · For self-purchased cabinets, the grounding wire from the cabinet to the grounding of the computer room requires the use of yellow and green two-color multi-strand flexible wires

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

Energy-saving design and implementation in metro weak current

Dec 4, 2021 · It is proposed that the five weak current systems, namely platform doors, communication systems, signals, integrated monitoring and automatic fare collection, should

How to design the weak electric room of the commercial

The incoming line is a three-phase five-wire system All strong and weak current cables in the machine room should be laid through metal grooves (pipes). Strong and weak current cables

6 FAQs about [How to use the weak current backup battery cabinet]

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

How do I connect a battery to a ups?

Connect and route cables from positive (+) and negative (–) terminals in the bottom of the first battery cabinet into the UPS cabinet. Connect the (+) lead to terminal E4 (+) and the (–) to terminal E5 (–) in the UPS cabinet.

How do you secure a battery cabinet?

Secure the battery cabinet position by lowering the leveling feet until cabinet is not resting on the casters. Ensure the cabinet is level and matches the height of the installed UPS cabinet. NOTE Two cabinet joining brackets are provided in the field kit for securing each cabinet at the top and bottom.

What is a battery cabinet?

The battery cabinet is designed for industrial or computer room applications and should be handled with appropriate care. This battery cabinet contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS

How do I connect A Powerware 9390 ups to a battery cabinet?

Refer to the appropriate Powerware 9390 UPS Installation and Operation Manual, as referenced in paragraph 1.6, for UPS cabinet terminal locations. A UPS‐to‐battery wiring harness is supplied inside the first battery cabinet. Use pressure and bus bar terminations, as necessary, for connecting cables between the UPS and battery cabinet.

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

Learn More

- How to increase the current and voltage of the battery cabinet

- How much current does the battery cabinet have

- How much current does a long-life battery cabinet usually have

- How to assemble the c16 battery cabinet

- What is the internal current of the battery cabinet

- Discharge current of nickel-cadmium battery in energy storage cabinet

- How to connect 32 batteries in a UPS battery cabinet

- How big a battery cabinet can be placed in the center box

- How to deal with the grounding of the battery cabinet shelf

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

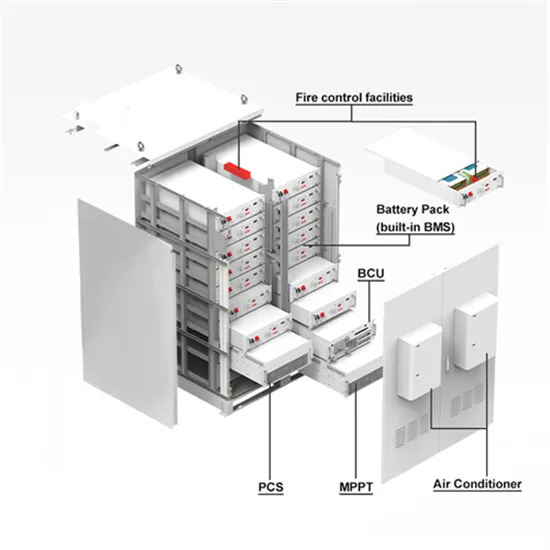

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.