4 Keys to a Properly Grounded Battery in the Trunk

Sep 18, 2021 · When I was restoring and improving the performance of one of my classic cars, I came across the idea that my car battery could be moved from

DC battery cabinet grounding requirements and standards

• Note: All cabinet systems require grounding. 5.4 Environmental Conditions The cabinet configuration nomenclature refers to "X wide" x "Y high", this is the number of battery jars per

USER MANUAL BATTERY CABINET

Jun 26, 2025 · 5.1 PRODUCT DESCRIPTION The EG4® Welded Indoor Cabinet is a great addition to a new or expanding Energy Storage System (ESS). Made of high-quality steel with

Why can t the battery cabinet be grounded

Does a battery cabinet need a grounding electrode? Article 250.162, Direct-Current Circuits and Systems to be Grounded, applies to systems operating at greater than 60 V but not greater

Do battery racks need to be grounded?

May 3, 2025 · Yes, battery racks require proper grounding to ensure electrical safety and system stability. Grounding mitigates shock risks and stabilizes voltage levels, but improper

importance of earthing a rack battery and its cabinet

Jan 16, 2023 · The batteries are bolted to the rack, with 4 bolts each. This should be good enough for bonding everything together (you can verify this with a meter). The bond wire going from

How to Properly Ground a Car Battery

Apr 4, 2025 · To properly ground a car battery, you need to securely connect the negative terminal to a clean, unpainted metal surface on the vehicle''s chassis. Many car owners

Earthing the battery cabinet

Jun 13, 2025 · Earth the battery management system during installation. Connect the supplied grounding cable to the battery cabinet grounding point (hexagon socket, AF13, torque: 8 Nm).

Why Should Battery Racks Be Grounded? Safety and

Jun 15, 2025 · Battery racks should be grounded to prevent electrical hazards, reduce fire risks, and ensure compliance with safety standards like NEC Article 480 and NFPA 70. Grounding

Why can t the battery cabinet be grounded

Grounding - Ensure that all batteries are installed in the EG4 battery rack using the mounting hardware provided. Connect a grounding conductor to the grounding lug (or screw) on the rack

Server Rack Grounding | How To, Requirements,

Mar 24, 2022 · Server rack grounding is important. Learn if you should ground your server rack, get server rack grounding requirements, & discover how to

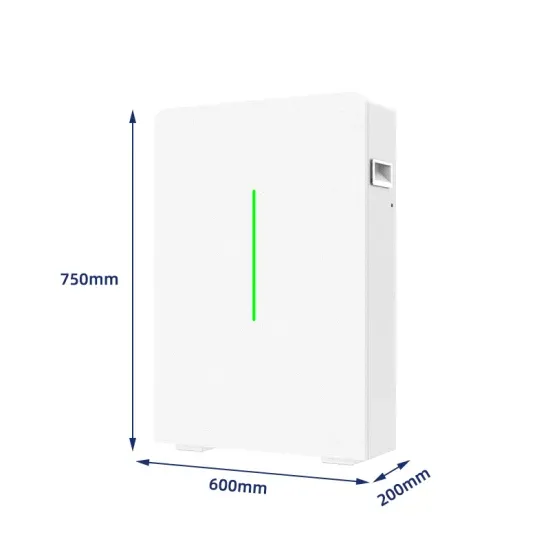

Key Considerations for Installing a Lithium Battery Cabinet

Installing a lithium battery cabinet like Pytes'' V - BOX - OC needs attention to various factors. Space, environment, accessibility, security, foundation, electricals, and ventilation are crucial

What is the grounding resistance of the energy

Mar 23, 2024 · Grounding resistance refers to the ability of an electrical system to safely dissipate fault currents into the ground, 2. Adequate grounding

New Energy Battery Cabinet Grounding

For exterior cabinet grounding, locate the safety cabinet''''s ground screw just below the green dot on the right hand side of the cabinet. Use a 5/16" (8 mm) wrench or nut driver to loosen screw.

Microsoft Word

Nov 15, 2017 · The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Installing a Battery Grounding Failure Detector

Jun 12, 2025 · Mount the battery grounding failure detector onto the bracket and reinstall the bracket in the cabinet. Figure 3-43 Installing a battery grounding failure detector

7 grounding, 8 remote battery cabinets/racks, 9 battery

The battery cabinets have ground studs. Use an equipment-grounding conductor to connect the lugs of the cabinets together and to connect the cabinets to the ground bus bar in the UPS

How to replace the damaged parts of a Grounding Resistance Cabinet?

Aug 13, 2025 · A grounding resistance cabinet is an essential electrical device used to measure and control the grounding resistance of electrical systems. It plays a vital role in ensuring the

How To Ground Car Battery Safely And Quickly: The Ultimate

Jun 2, 2024 · Grounding a car battery is a crucial step in maintaining its proper functioning and ensuring the safety of your vehicle. By connecting the battery''s negative terminal to the

OSHA Guidelines: Do Flammable Cabinets Need to be

Sep 4, 2023 · What To Know Grounding refers to the use of a low-impedance path to the earth, which can provide a safe outlet for electricity in the event of a short circuit or other electrical

What is the grounding resistance of the energy

Mar 23, 2024 · Understanding the grounding resistance of an energy storage cabinet is essential for ensuring the safety and efficiency of electrical systems

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Battery Cabinet Working Space Front Aisle Floor Loading

Ensure the technique and hardware used in securing the battery cabinet can support the. Direct-current ground-fault detection. Not all battery systems have DC ground-fault detection but

Why Should Battery Racks Be Grounded? Safety and

Jun 15, 2025 · Battery racks are grounded using copper conductors bonded to the rack structure and connected to a grounding electrode system. Techniques include: 1. Direct bonding to

Grounding Requirements Inside the Cabinet

At least one ground terminal at the front door, rear door, and side panel of the cabinet should be properly connected to the ground terminal of the cabinet. At least one ground terminal at the

Learn More

- How long is the shelf life of the battery in the energy storage cabinet

- How much does a lithium battery cost in an energy storage cabinet

- How to replace the battery in photovoltaic energy storage cabinet

- How to replace the new energy battery cabinet monomer

- How much power does the battery cabinet have in total

- How long does it take to repair a mobile lithium battery cabinet

- How to install the crossbeam of the battery cabinet

- How to check the battery photovoltaic of the energy storage cabinet

- How much does a new energy battery cabinet cost per kilowatt-hour

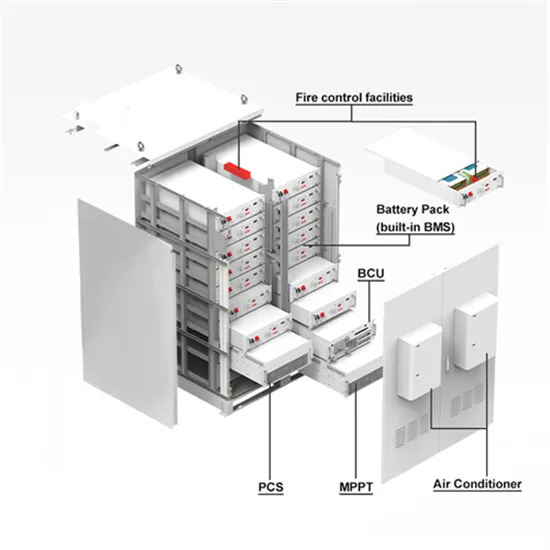

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.