Internal structure diagram of lithium battery energy

structure of a lithium-ion battery is complex and consists of several key components. The outermost layer is the casing,which contains the internal components and protects them from

Internal Resistance series. Part II: How to determine the

5 days ago · The lithium ion battery internal resistance refers to the resistance of the current flowing through the battery when the battery is working, and indicates the degree of

How to measure the internal current of the battery cabinet

The most common method for determining a battery''s internal resistance is to connect it to a circuit with a resistor, measure voltage through the battery, calculate current, measure voltage

Internal Ohmic Measurement vs. Capacity Testing – 4 Key

Dec 18, 2024 · Internal ohmic measurement provides insight into the battery''s internal condition and resistance, while capacity testing assesses its ability to store and deliver energy.

Battery Heat Generation Calculator

Aug 2, 2024 · This will give you the heat generated in watts. What is Battery Heat Generation? Battery heat generation refers to the heat produced by a battery during its operation. This heat

NetSure™ 211 Series -48 VDC Battery Cabin

Jan 31, 2023 · Connect the second battery cabinet''s battery cable terminated in an Anderson connector to the fixed mating Anderson connector located on the first battery cabinet.

How to calculate the heat dissipated by a battery pack?

Aug 22, 2018 · I have a battery pack consisting of 720 cells. I want to calculate the heat generated by it. The current of the pack is 345Ah and the pack voltage is 44.4Volts. Each cell has a

How to determine the internal resistance of the battery

different battery types along with the required test circuits and calculations. We will cover: Importance of battery internal resistance; Factors affecting internal resis

What is the voltage of the energy storage battery cabinet?

Aug 16, 2024 · The voltage of energy storage battery cabinets typically ranges from 12V to 800V, influenced by application requirements, technology used, and the configuration of battery cells.

Internal Resistance of a Battery: How to Measure

Aug 29, 2024 · What is Battery Internal Resistance? Battery internal resistance is a crucial parameter that determines the performance and efficiency of a

Specifications and requirements for battery cabinets in

is the most common type used in both indoor and outdoor battery cabinets. Due to the low heat generated by battery systems during normal operation, dedicated battery cabinets require

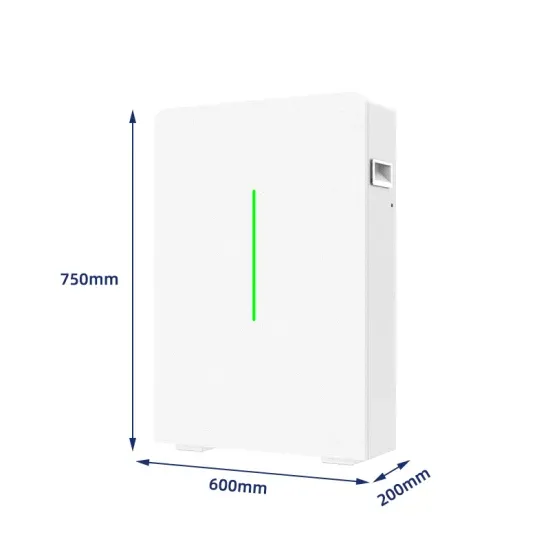

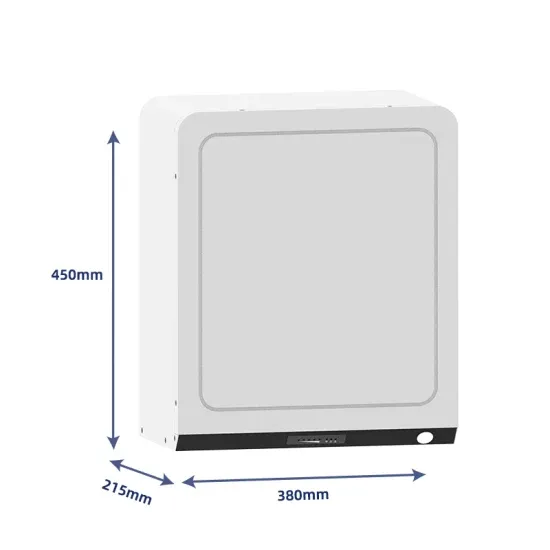

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · The dimensions of the cabinets are the outside dimensions, so it is important to take into account the thickness of the material and body stiffeners that are attached to the

Energy storage battery cabinet structure diagram

Battery Energy Storage System Structure The storage device is controlled by the Monitors &Control module,also referred to as BMS (Battery Management System). It is a real-time

What is Battery Internal Resistance?

Feb 1, 2025 · Battery internal resistance is the opposition to the flow of current within a battery, caused by its chemical composition, electrode materials, and design. High internal resistance

Eaton 93PM Integrated Battery Cabinet-Large and Large

Mar 31, 2025 · Figure 12 shows the location of the battery breaker in the 93PM Integrated Battery Cabinet-Large or 93PM Integrated Battery Cabinet-Large High Rate (432V). Figure 13 shows

What is the starting current of the first-level energy

Battery racks can be connected in series or parallel to reach the required voltage and current of the battery energy storage system. These racks are the building blocks to creating a large,

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Battery Internal Resistance & Short Circuit Current.

Dec 16, 2016 · Never the less, values of the internal resistance may be used to estimate the actual short circuit current in a battery system. This article

Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · 1 Introduction During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load.

New UL Standard Published: UL 1487, Battery Containment

2 days ago · Learn about the first edition of UL 1487, the Standard for Battery Containment Enclosures, a binational standard for the United States and Canada published by UL

How to test the internal current of the battery cabinet

Direct Current Internal Resistance, DCIR or DCR can be measured with a battery tester by applying a low current followed by higher current on the battery within a short period, and

6 FAQs about [What is the internal current of the battery cabinet ]

What should a battery's internal resistance be?

Ideally, a battery's internal resistance should be zero, allowing for maximum current flow without any energy loss. In reality, however, as illustrated in Fig.1, internal resistance is always present. Let's consider an example to illustrate this. The battery voltage is determined by the internal resistance and the output current.

What does internal resistance mean in a battery?

Internal resistance can be thought of as a measure of the “quality” of a battery cell. A low internal resistance indicates that the battery cell is able to deliver a large current with minimal voltage drop, while a high internal resistance indicates that the battery cell is less able to deliver a large current and experiences a larger voltage drop.

How to measure internal resistance of a battery?

One can mention the IEC 61960 standard or PNGV (Partnership for a New Generation of Vehicles) procedure for example. Measurement methods for the internal resistance of batteries can be divided up into two categories: DC (Direct Current) techniques and AC (Alternating Current) techniques.

What is lithium ion battery internal resistance?

The lithium ion battery internal resistance refers to the resistance of the current flowing through the battery when the battery is working, and indicates the degree of obstruction of a circuit element to the transmission of current. General lithium ion battery internal resistance is divided into AC internal resistance and DC internal resistance.

How does internal resistance affect a battery's current-carrying capacity?

When the battery's internal resistance, R DC, is 1 Ω, and the load, R, is 9 Ω, the battery outputs a voltage of 9 V. However, if the internal resistance increases to 2 Ω, the output voltage drops to approximately 8.2 V. In summary, internal resistance influences a battery's current-carrying capacity.

What if the internal resistance of a battery cell is not provided?

If the internal resistance of the battery cell is not provided by the manufacturer, as we’ll see in this article, using the discharge characteristics of the battery cell, we can calculate the internal resistance of the battery cell, for a specific state of charge value.

Learn More

- What is the appropriate discharge current of the energy storage cabinet battery

- What is the current of the battery cell in the battery cabinet

- What power supply should be used with the battery cabinet

- What battery cabinet companies are there in San Diego

- What are the embedded parts of the battery cabinet

- What are the consequences of missing phase in battery cabinet

- What brands are there in Nicaragua s battery cabinet factories

- What is the cold plate of the battery cabinet

- What is the heat of the battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.