UPS WITH A BATTERY SYSTEM 101. EDUCATION FOR

Jan 10, 2023 · The most common topology of a UPS with a battery system is the dual conversion technology with a line up and match battery cabinet with VRLA batteries. The following outline

What is the voltage of the energy storage battery cabinet?

Aug 16, 2024 · The voltage of energy storage battery cabinets typically ranges from 12V to 800V, influenced by application requirements, technology used, and the configuration of battery cells.

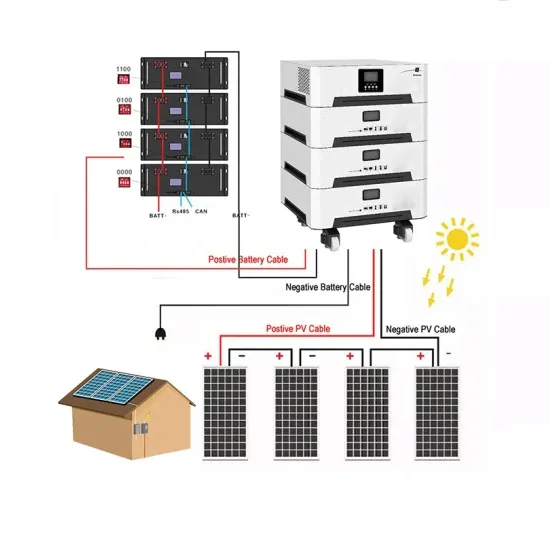

How to design an energy storage cabinet: integration and

Jan 3, 2025 · The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

The Ultimate Guide to Power Cabinet: Everything You Need

Nov 1, 2024 · A power cabinet is a storage unit designed to house and protect charging equipment, power supplies, and devices. These cabinets are often built with durability in mind,

直流柜英文说明书.cdr

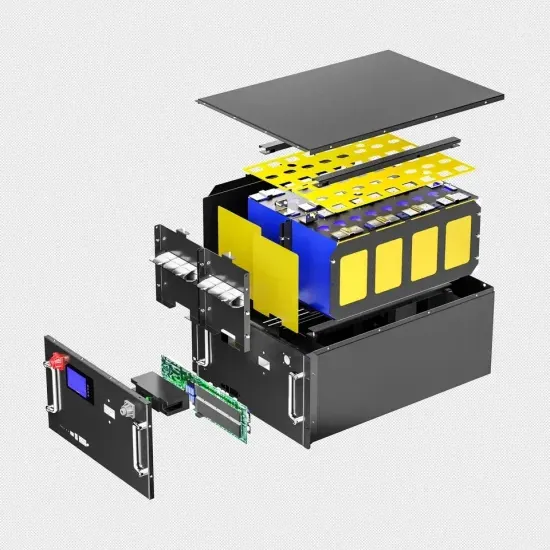

Jun 4, 2024 · 1. Basic components The DC cabinet mainly collects and distributes current to each battery cluster to realize charge and discharge management function. The DC cabinet consists

Which Power Supply should I use? | ControlByWeb

Aug 18, 2025 · If you install it in an environment where 12V batteries are used either for primary or backup power, you could connect the battery voltage directly to the ControlByWeb device. If

Guidelines for storage & usAGE of lead acid batteries

May 19, 2022 · 2 Lead-Acid Batteries Lead-acid batteries are the most widely used electrical energy storage, primarily for uninterrupted power supply (UPS) equipment and emergency

Cabinet-type lithium battery as backup power supply and

Jan 13, 2025 · Cabinet-type lithium battery is an energy storage device or power supply device designed in the form of a cabinet with lithium-ion battery as the core. It is usually designed to

A Guide To UPS Room Layout | Carter Sullivan

May 4, 2020 · We explore the fundamentals of UPS room layout and the things you need to consider when deciding where to locate your essential power protection systems.

UPS WITH A BATTERY SYSTEM 101. EDUCATION FOR

Jan 10, 2023 · The above questions are the basics on selecting a UPS with battery system, however there are many factors to consider. The most common topology of a UPS with a

China Power Supply Cabinet, Power Supply Cabinet

The Power Supply Cabinet is an essential part of our Power Distribution Cabinet & Box offerings.When selecting a power distribution cabinet or box, important factors include size,

How to design an energy storage cabinet: integration and

Jan 3, 2025 · System redundancy: The energy storage cabinet should be designed with redundant power supplies and key components (such as inverters, BMS) to improve the

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · battery cabinet are battery disconnect circuit breaker alarm lead assemblies. Refer to the power system installation manual to use these alarm leads to connect the battery cabine

Eaton''s Lithium-ion UPS Battery Q

Aug 24, 2024 · UPS protected'' source for the BMS. Gen 1 (white cabinet units, have a transformer in the conduit landing box that steps up 208Vac from the UPS to 480Vac to un the cabinet

How to Choose the Right Battery Cabinet for Your Needs

Jan 30, 2025 · Choosing the right battery cabinet involves careful consideration of your needs, safety features, build quality, and maintenance. Think about how the cabinet will be used, and

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · UNDERSTANDING UPS SYSTEMS AND BATTERIES Putting the ''U'' in UPS When it comes to an uninterruptible power supply (UPS), the battery is one of the most important

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The term line-up-and-match refers to battery cabinets that are physically attached to the UPS, share internal wiring, and use the battery cabinet breaker as the battery isolation

UPS Battery Cabinet Upgrade, Retrofit, Replacement

5 days ago · Use the existing battery cabinet or rack to find out what batteries you currently have in place. For proper disposal of spent batteries, explore each battery manufacturer''s safety

6 FAQs about [What power supply should be used with the battery cabinet]

What type of batteries are used in energy storage cabinets?

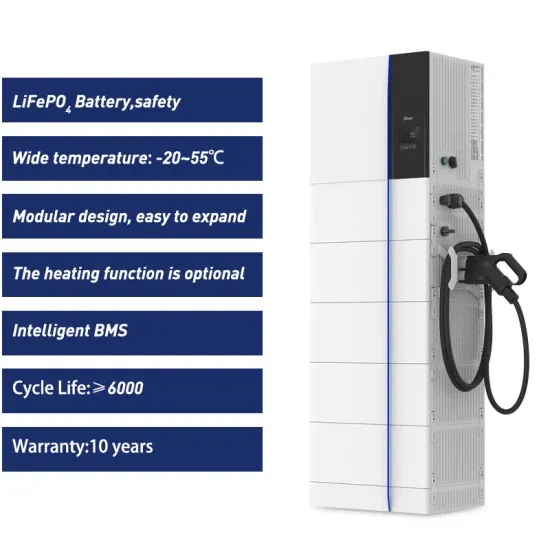

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

What power supplies can be used for battery charging?

Constant current control power supplies and power supplies with a CVCC function are recommended for battery charging.

What is included in the Battery Cabinet Manual?

This manual contains important instructions that should be followed during installation and operation of the battery cabinet. This product is designed for commercial / industrial use only, with UPS systems. It is not intended for use with life support and other designated critical devices.

How do I connect a battery cabinet to a power system?

Procedure 1. Furnished with the battery cabinet are battery disconnect circuit breaker alarm lead assemblies. Refer to the power system installation manual to use these alarm leads to connect the battery cabinet battery disconnect circuit breaker alarm into the power system alarm circuits.

Should UPS batteries be installed on racks or in cabinets?

Early on in a UPS design a decision must be made on whether batteries should be installed on racks or in cabinets. Both have pros and cons. The following are typical design considerations.

Why do you need a battery cabinet?

Ease of use is one of the principle selling points for battery cabinets. It is convenient to service the equipment when the UPS and the battery (ies) are right next to each other. Conversely, it is inconvenient to have to go to a separate room when open-rack batteries are installed.

Learn More

- What type of battery is used for energy storage power supply

- Communication power supply supporting battery cabinet

- Battery cabinet production site power supply

- Battery cabinet production module site power supply

- How to convert lithium battery station cabinet into outdoor power supply

- Kuwait City New Energy Battery Cabinet Professional Communication Power Supply

- What size of battery should I choose for outdoor power supply

- Can UPs power supply be used as energy storage battery

- What brand of aluminum is used in the power battery pack box

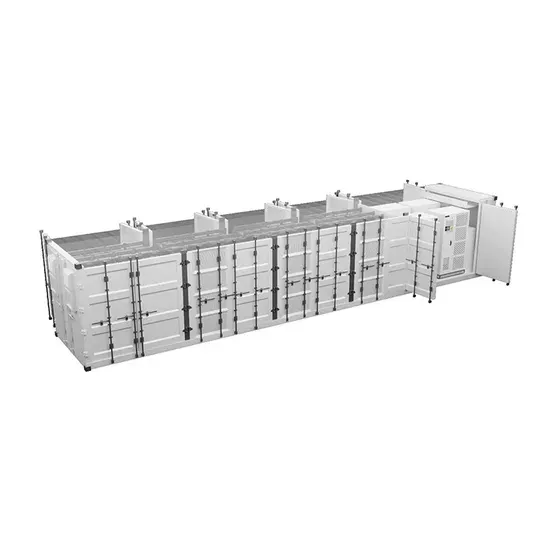

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.