How to design an energy storage cabinet: integration and

Jan 3, 2025 · The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance

Battery cabinet production design drawings

Unified Power offers a complete line of battery cabinets for both UPS and Telecom Applications. These cabinets can be configured to match OEM cabinets and offer a competitive option for

ESS-GRID Cabinet Brochure EN-250401

Jul 15, 2025 · The ESS-GRID Cabinet series are outdoor battery cabinets for small-scale commercial and industrial energy storage, with four diferent capacity options based on diferent

UPS Energy Storage Systems | ABB Electrification U.S.

Aug 19, 2025 · When you want power protection for a data center, production line, or any other type of critical process, ABB''s UPS Energy Storage Solutions provides the peace of mind and

Automate battery production with robotics and proven

Automation in battery production From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · Segments of the production line The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and

6 FAQs about [Battery cabinet production module site power supply]

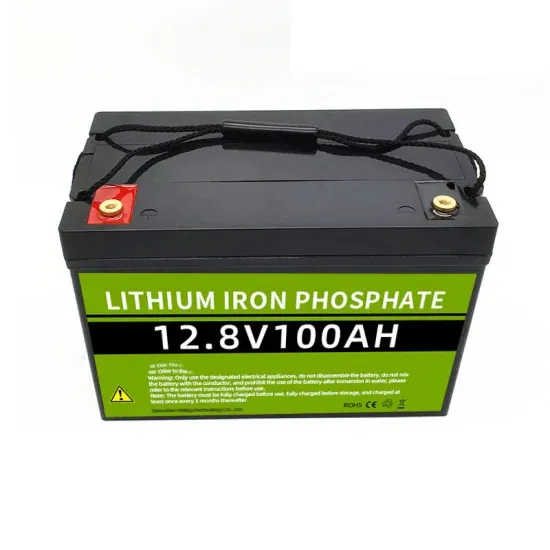

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

Why do energy storage cabinets use STS?

STS can complete power switching within milliseconds to ensure the continuity and reliability of power supply. In the design of energy storage cabinets, STS is usually used in the following scenarios: Power switching: When the power grid loses power or fails, quickly switch to the energy storage system to provide power.

Can a battery cabinet be deployed outside a smart module?

Battery cabinets or racks can also be deployed outside smart module A (batteries deployed outside) or smart module B. The front door is a single door, and the rear door is a double one. Shoto batteries are supported.

What is a lithium battery management system (BMS)?

Lithium battery modules are usually composed of multiple battery cells, so they need to be monitored and managed by a battery management system (BMS). Battery Management System (BMS): BMS is responsible for monitoring the status of the battery to ensure that each battery cell is within a safe operating range.

Learn More

- Battery cabinet production site power supply

- New Energy Battery Cabinet Power Cord Production

- Uninterruptible power supply battery cabinet 32 pieces

- Battery cabinet adjustable power supply charging

- Connection between communication power supply and battery cabinet

- Battery cabinet to outdoor power supply

- Communication power supply supporting battery cabinet

- Power supply for energy storage cabinet liquid cooling processing site

- Principle of Emergency Power Supply Battery Cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.