Overview of Signal Cables between the Battery Cabinets and

The connection of auxiliary contacts is dependent on the number of battery breakers supported by the UPS. In the examples below two banks of battery breakers are supported.

Smart control cabinets Solutions for automating the

Jul 2, 2024 · Wireless connectivity for easy and secure access to remote communications assets The growing demand for increased automation of existing secondary substations challenges

Communications System Power Supply Designs

Apr 1, 2023 · The power supply designer must choose between buying off-the-shelf POL and IBC modules or attempting to reduce costs and improve efficiency by embedding a semiconductor

VertivTM Liebert® ITA2 Battery Cabinet

Feb 27, 2020 · Connect to the communication port on the UPS and Communication Port 1 on the first battery cabinet. Connect the first string of additional battery cabinet systems. Connect a

Power Supply Requirements for ICT rooms

Nov 5, 2020 · The minimum requirement for main electrical panels for normal power supply, emergency supply and uninterruptible power supply is that they shall be located in separate

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Communication network cabinet battery assembly

The battery cabinet for base station is a special cabinet to provide uninterrupted power supply for communication base stations and related equipment, which can be placed with various types

直流柜英文说明书.cdr

Jun 4, 2024 · Connect the DC24V wire between the DC cabinet and the battery cluster (high voltage box). The power supply DC24V is output from the high voltage box to supply power to

Digital communication and applications of

Sep 9, 2021 · From rotary phones to smartphones, from traditional fuel vehicles to digitally controlled electric vehicles, switching power supplies also have the exact differences between

Tutorial on converting batteries in communication

The battery cabinet for base station is a special cabinet to provide uninterrupted power supply for communication base stations and related equipment, which can be placed with various types

How to design an energy storage cabinet: integration and

Jan 3, 2025 · This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

Communication power supply cabinet and communication power supply

The invention discloses a communication power supply cabinet and a communication power supply cabinet temperature control method. The communication power supply cabinet

The power connection control auto on-off grid switching cabinet

The power connection control auto on-off grid switching cabinet (abbreviated PCC switching cabinet) is an electrical device capable of automatically switching between grid-connected and

Battery detection power supply for communication

To protect your smart home from power outages, install a battery backup system in the communication cabinet. Select a UPS (Uninterruptible Power Supply) that can support the

6 FAQs about [Connection between communication power supply and battery cabinet]

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

Why do energy storage cabinets use STS?

STS can complete power switching within milliseconds to ensure the continuity and reliability of power supply. In the design of energy storage cabinets, STS is usually used in the following scenarios: Power switching: When the power grid loses power or fails, quickly switch to the energy storage system to provide power.

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

What is a multi-output power supply design?

Multiple output designs may also employ a complex regulation scheme which senses multiple outputs to control the feedback loop. Voice-over-Internet-Protocol (VoIP), Digital Subscriber Line (DSL), and Third-generation (3G) base stations all necessitate varying degrees of complexity in power supply design.

How does input voltage sensing work?

Input voltage sensing logic turns on the top FET Q2, which is connected to the 400V bus, when the AC main supply voltage is within the correct range. During AC line power outages, top FET Q3 is activated to power the converter from the back-up battery.

What types of power systems are used in communications infrastructure equipment?

Communications infrastructure equipment employs a variety of power system components. Power factor corrected (PFC) AC/DC power supplies with load sharing and redundancy (N+1) at the front-end feed dense, high efficiency DC/DC modules and point-of-load converters on the back-end.

Learn More

- Belgrade Intelligent Battery Cabinet Communication Power Supply

- Communication power supply supporting battery cabinet

- How to connect the power supply battery of the communication base station

- Battery cabinet to outdoor power supply

- Indonesia outdoor communication battery cabinet supply

- Battery cabinet adjustable power supply charging

- How to convert lithium battery station cabinet into outdoor power supply

- Battery cabinet plus mobile power supply

- Hybrid power supply of battery energy storage system for Saint Lucia communication base station

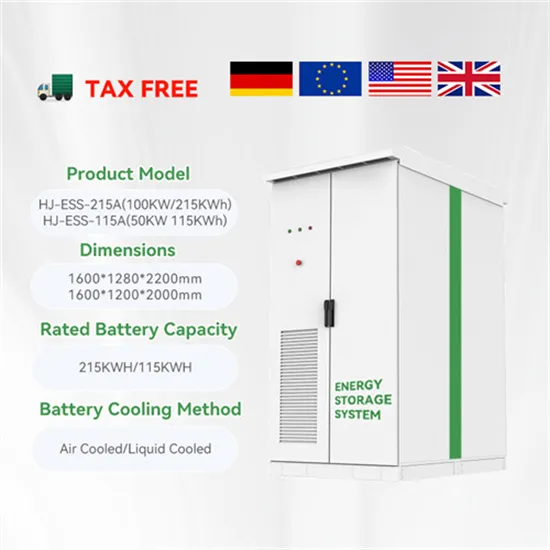

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.