n-Type Crystalline Silicon Photovoltaics: Technology,

This book conveys current research and development for n-type solar cells and modules. With a systematic build-up, chapters cover the base material, wafer production, and the cell concepts

N-type TOPCon: Combating LID and LeTID for all locations

Dec 21, 2021 · More and more solar cell manufacturers focus on high-efficiency solar cells. The industry is moving towards N-type technology and cell efficiency has been improving

Solar Module Technology Comparison: N-type vs PERC vs

Feb 26, 2025 · Understanding the differences between N-type, PERC, and Thin-film solar panels helps consumers, installers, and investors make informed decisions. Snippet paragraph: N

Comparison of N-type and P-type cells for photovoltaic modules

Aug 18, 2023 · Perovskite photovoltaic modules are one of them, which use perovskite-type metal halide semiconductors as light-absorbing layer materials to absorb photons generate electron

Differences Between P-Type and N-Type Solar Panels

In the vast firmament of the new energy photovoltaic field, each leap in technology is a brave exploration of the boundaries of solar energy utilization efficiency. P-type and N-type solar

Comparison of potential-induced degradation (PID) of n-type and p-type

Oct 15, 2018 · The main suspects for the PID mechanism of p-type solar cells are sodium ions (Na+), which drift due to the negative electric field (electric field is oriented from the grounded

What''s N-Type Technology and What Does it Mean for Solar?

Sep 27, 2022 · Trina''s New N-Type Cell Paves the Way As Trina unveiled its new 210×210 mm monocrystalline N-Type i-TOPCon solar cell, it also announced that it set a new world record

Environmental impact assessment of the manufacture and use of N

Sep 10, 2024 · Carbon emissions for both the P-type and N-type PV modules were lower only during the cell production phase but higher during the other stages when compared to the P

N-Type vs P-Type Solar Cells: Understanding the

May 1, 2024 · There are two main types of solar cells used in photovoltaic solar panels – N-type and P-type. N-type solar cells are made from N-type silicon,

What''s N-Type Technology and What Does it Mean for Solar?

Sep 27, 2022 · Simply put, the main difference between these two types is the number of electrons each contains. To take a step back, all standard silicon solar panels are composed

N-type vs P-type Panels – Which Should You

2 days ago · N-type cells are also less prone to metallic impurities that affect P-type cells and have a higher temperature tolerance. The main disadvantage of

Gain a Competitive Edge with N-type TOPCon: The New

Aug 9, 2023 · This approach has allowed Trina to develop cutting-edge n-type TOPCon PV cells with remarkable efficiency rates and exceptional reliability, enabling the Vertex N and Vertex

Analysis of PV Modules and N-type Silicon Solar Cells with Different

Jan 1, 2014 · The goal of this paper is to present the analysis of PV modules and silicon solar cells developed on phosphorus-doped Czochralski wafers with different metal grid on the rear

Solar Module Technology Comparison: N-type vs PERC vs

Feb 26, 2025 · Solar Module Technology Comparison: N-type vs PERC vs Thin-film I. Introduction Solar photovoltaic (PV) technology has evolved significantly over the years. Understanding the

Jinko Solar n-type TOPCon technology and product

May 9, 2024 · Jinko n-type TOPCon Technology The photovoltaic industry''s technology is constantly evolving, following the trends of high energy density and low levelised cost of

N-type solar cells: advantages, issues, and current scenarios

Jul 5, 2017 · With the increasing market share of n-type wafers and the obtainability of n-type modules at suitable price levels, a higher awareness among product users about the LID issue

Progress in n-type monocrystalline silicon for high

May 21, 2024 · ABsTrACT Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are

6 FAQs about [Photovoltaic n-type modules and n-type cells]

What is a p n type solar cell?

These wafers form the basis of a solar cell. It is at this point that p and n-type cells diverge. To create a semiconductor junction that will induce current flow the wafers are doped (coated) with either boron (p-type) or phosphorus (n-type). The creation of a solar module from raw material to finished product.

What is the difference between P-type and n-type solar cells?

The main difference between p-type and n-type solar cells is the number of electrons. A p-type cell usually dopes its silicon wafer with boron, which has one less electron than silicon (making the cell positively charged). An n-type cell is doped with phosphorus, which has one more electron than silicon (making the cell negatively charged).

How do n-type and P-type solar cells generate electricity?

N-type and P-type solar cells generate electricity through the photovoltaic effect. This process relies on the semiconductor properties of silicon, which is the main material used in solar cells. In an N-type cell, phosphorus or arsenic atoms are added to the silicon, providing extra electrons. These electrons can move freely through the material.

What are the different types of solar cells?

The materials and structure of a solar cell, vary slightly depending on the technology used to manufacture the cell. Traditional cells feature Aluminum Back Surface Field (Al-BSF), but there are newer technologies in the market including PERC, IBC, and bifacial technology.

Are n-type C-Si solar cells better than P-type solar cells?

In recent years, there has been many developments in n-type c-Si solar cells basically due to the advantages of n-type c-Si wafers over p-type wafers. However, there are some limitations in making n-type solar cells considering the technologies involved to fabricate p-type cells.

Are n-type solar cells good for LCOE?

With the increasing market share of n-type wafers and the obtainability of n-type modules at suitable price levels, a higher awareness among product users about the LID issue of p-type modules is expected soon, outlining another benefit of n-type solar cells in terms of LCOE.

Learn More

- Heterojunction photovoltaic modules and BC cells

- Photovoltaic cells and modules gross profit and net profit

- Island photovoltaic bifacial modules

- Differences between photovoltaic module cells

- The relationship between Huawei s photovoltaic cells and components

- Structure of flat-plate solar photovoltaic modules

- Conversion rate of monocrystalline silicon photovoltaic modules

- Chromium telluride thin film photovoltaic modules

- Sources of solar photovoltaic modules in Maputo

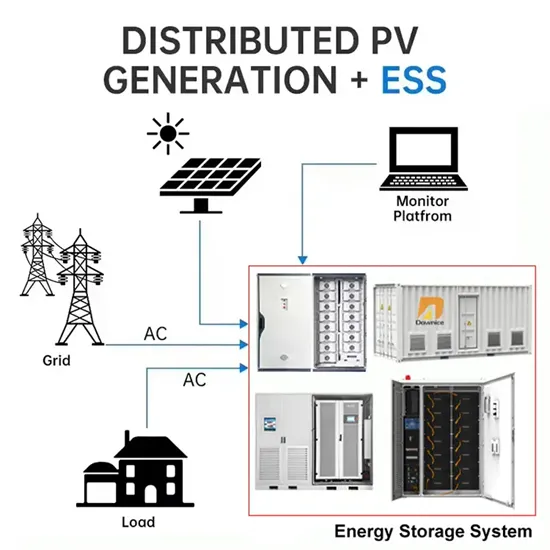

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.