POWER LINE COMMUNICATION BETWEEN AN

Apr 11, 2020 · 1. Introduction Currently, the right functioning of a motor fed by three phase current requires data transmission between the motor and the inverter. Information from sensors such

Solar Power Line Communication Reference Design (Rev

Jan 13, 2025 · Explore the benefits of the THS6222 device distortion performance and output drive, the THVD8000 on or off keying modulation, and the Arm Cortex-M0+ MCU hardware

Protection Challenges and Practices for Interconnecting

Jul 27, 2023 · Figure 4 shows transmission interconnection of two inverter-based generatingstations to the integrated power system. The solar generating stationis

ABB inverter station PVS800-IS – 1.75 to 2

May 29, 2019 · The station houses two ABB central inverters and embedded auxiliary power, monitoring and air filtration systems. It enables easy and rapid connection to a MV transformer

A Dedicated Line-Based 5G-NR Dedicated Network Communication

Aug 29, 2023 · This article delves into the challenges and solutions of communication between unmanned systems (UMS) and ground stations (GS), with a specific focus on an in-depth

TIDA-010935 reference design | TI

Nov 13, 2023 · This reference design shows how to implement a Power Line Communication (PLC) for HV DC and AC lines. In particular this design has been done to show communication

Medium Voltage Power Station | 1500V 4400kVA Solar Inverter

SG4400UD-MV-US medium voltage power station features 4400 kVA output and 1500V design, which is ideal for large-scale solar projects, featuring a modular design and smart monitoring.

Manual on Transmission Planning Criteria 2023

Jun 20, 2023 · Switching over-voltages: These are over-voltages generated during switching of lines, transformers and reactors etc. having wave fronts of 250/2500 micro sec. Surge

An Accelerated Distance Protection Scheme for the Lines

Jun 6, 2023 · Distance relay based pilot protection schemes are commonly employed in industrial relays to provide fast tripping of the faulty transmission lines. However, the probable

Inverter communication mode and application scenario

Jul 15, 2025 · When using GPRS/4G communication mode, each inverter needs to be equipped with a data collector with GPRS/4G communication module, built-in SIM card or use an

A Dedicated Line-Based 5G-NR Dedicated Network Communication

This article delves into the challenges and solutions of communication between unmanned systems (UMS) and ground stations (GS), with a specific focus on an in-depth exploration of

Powerline communications strategy enabling fully

Oct 5, 2017 · Cascaded or distributed module-level inverters are becoming increasingly desirable for photovoltaic applications. The authors have demonstrated an AC-stacked to

A Dedicated Line-Based 5G-NR Dedicated Network Communication

Aug 29, 2023 · This article delves into the challenges and solutions of communication between unmanned systems (UMS) and ground stations (GS), with a specific focus on an in-d

Simulation and Classification of Mobile Communication Base Station

Dec 16, 2020 · In recent years, with the rapid deployment of fifth-generation base stations, mobile communication signals are becoming more and more complex. How to identify and classify

Inverter Interference on Charging Communication System

Sep 8, 2022 · Power line communication (PLC) is widely used in combination with the control pilot (CP) as communication system between the charging station and the electric vehicle (EV) in

Detailed explanation of inverter communication

1 day ago · The article comprehensively discusses the communication methods used by photovoltaic inverters in the digital and intelligent era of photovoltaic

Communication Base Station Smart Hybrid PV Power Supply

The Telecom Base Station Intelligent Grid-PV Hybrid Power Supply System helps telecom operators to achieve "carbon reduction, energy saving" for telecom base stations and machine

A Dedicated Line-Based 5G-NR Dedicated Network

Aug 28, 2023 · This article delves into the challenges and solutions of communication between unmanned systems (UMS) and ground stations (GS), with a specific focus on an in-depth

A Dedicated Line-Based 5G-NR Dedicated Network Communication

Aug 28, 2023 · This article delves into the challenges and solutions of communication between unmanned systems (UMS) and ground stations (GS), with a specific focus on an in-depth

6 FAQs about [Dedicated line communication base station inverter]

What are the characteristics of different communication methods of inverters?

The characteristics of different communication methods of inverters are obvious, and the application scenarios are different. In order to better weave the underlying network of energy digitization and intelligent development, choose the most appropriate communication method according to local conditions.

How does a low voltage inverter work?

The data signal is connected to the low-voltage busbar through the power line on the AC side of the inverter, the signal is analyzed by the inverter supporting the data collector, and the communication is finally connected to the local power station management system or the cloud platform through the LAN or the Internet 2. Application scenario 4.

What is power line communication (PLC)?

Power Line Communication (PLC) is now used in multiple end-equipment applications. A good example are grid applications, where the necessary data is communicated from one device to another using the power cable as transmission lines. Hence the name; Power line communication.

How does tida-010935 work?

The 2 TIDA designs are connected to each other through jumpers J2 and J3 with two resistors that have the same value. The connection between the two TIDA designs was made with two 15Ω resistors, but also 20Ω and 100Ω were tried. Powering the TIDA-010935 requires an input voltage ranging from 13.5V to 50V.

How to power tida-010935 solar panel?

The connection between the two TIDA designs was made with two 15Ω resistors, but also 20Ω and 100Ω were tried. Powering the TIDA-010935 requires an input voltage ranging from 13.5V to 50V. This is done to match the varying output voltage from a solar panel as it is possible that the output power is not constant.

How do you connect a Tida board to a power supply?

The board is then connected to a power supply between 13.5V and 50V. Best design practice includes keeping the two boards isolated using different supplies. The 2 TIDA designs are connected to each other through jumpers J2 and J3 with two resistors that have the same value.

Learn More

- Communication base station inverter line standard

- Prague communication base station inverter grid-connected price

- How much does a communication base station inverter cost in Kabul

- Integrated communication base station inverter grid-connected technical specifications

- What is the level of the communication base station inverter

- Solution to the grid-connected inverter room of Mauritius communication base station

- The most used communication base station inverter in Russia is connected to the grid

- Porto Novo communication base station inverter grid-connected energy storage

- Huawei communication base station inverter grid-connected revenue

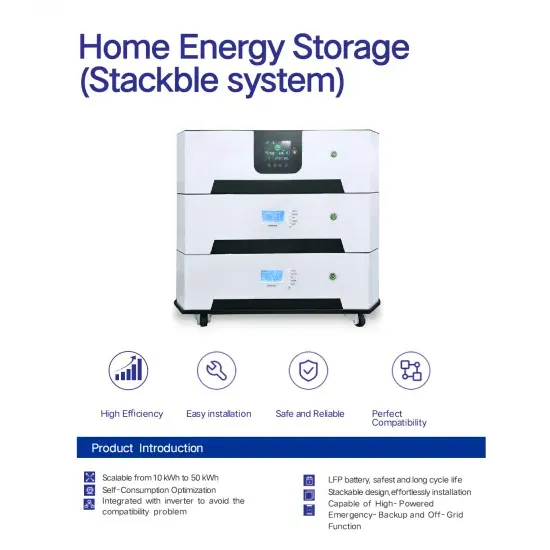

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.