ABB inverter station PVS800-IS – 1.75 to 2

May 29, 2019 · The station houses two ABB central inverters and embedded auxiliary power, monitoring and air filtration systems. It enables easy and rapid connection to a MV transformer

MV-inverter station: centerpiece of the PV eBoP solution

MV-inverter station: centerpiece of the PV eBoP solution Practical as well as time- and cost-saving: The MV-inverter station is a convenient "plug-and-play" solution offering high power

PowerPoint Presentation

Mar 21, 2024 · The substation is to be lifted from lifting brackets located as the base frame with the help of spreader and crane. The length of the four part lifting chain/sling is dependent on

Solar inverters ABB megawatt station PVS800-MWS 1 to

Jul 23, 2019 · The ABB megawatt station design capitalizes on ABB''s long experience in developing and manufacturing secondary substations for utilities and major end-users

Detailed explanation of inverter communication

1 day ago · The article comprehensively discusses the communication methods used by photovoltaic inverters in the digital and intelligent era of photovoltaic

Solar 1000 Watt Power Inverter For Communication Base Station

Mar 12, 2025 · Xindun''s solar 1000 watt power inverter provides efficient and stable power support for communication base stations in remote areas of Guyana, solving the problem of

Telecom Base Station PV Power Generation System

Feb 1, 2024 · The communication base station installs solar panels outdoors, and adds MPPT solar controllers and other equipment in the computer room. The power generated by solar

Communication Base Station Energy Solutions

A telecommunications company in Central Asia built a communication base station in a desert region far from the power grid. Due to harsh climate conditions and the absence of on-site

Solar inverters and inverter solutions for power generation

Mar 13, 2020 · Central inverter solutions In large ground-mounted multi-megawatt photovoltaic (PV) power plants the PV modules are typically installed uniformly mounted at ground level,

solar power for Base station

Aug 4, 2025 · The solar power for base station solution provides an economical and efficient energy solution for communication base stations, reducing operating costs, emissions, and

What Is an Inverter-Based Resource | High‑Fidelity

Types of inverter-based resources and where they are used in engineering Photovoltaic string inverter: Converts panel output to grid‑ready AC for residential and commercial rooftops.

Telecommunication base station system working principle

Jan 13, 2024 · The ESB-series outdoor base station system utilizes solar energy and diesel engines to achieve uninterrupted off grid power supply. Solar power generation is the use of

Communication and Control For Inverters

Dec 12, 2005 · Develop internationally-promulgated DER communication object model standards that will enable the strategic use of DER in ADA for functions such as Routine energy supply,

Communication Base Station Energy Power Supply System

The hybrid power supply system of wind solar with diesel for communication base stations is one of the best solutions to solve this problem. The wind-solar-diesel hybrid power supply system

3 FAQs about [What is the level of the communication base station inverter ]

What are the characteristics of different communication methods of inverters?

The characteristics of different communication methods of inverters are obvious, and the application scenarios are different. In order to better weave the underlying network of energy digitization and intelligent development, choose the most appropriate communication method according to local conditions.

How does a low voltage inverter work?

The data signal is connected to the low-voltage busbar through the power line on the AC side of the inverter, the signal is analyzed by the inverter supporting the data collector, and the communication is finally connected to the local power station management system or the cloud platform through the LAN or the Internet 2. Application scenario 4.

What is BMS + industrial and commercial energy storage inverter?

The complete set of energy control solutions of "BMS + industrial and commercial energy storage inverter" is suitable for industrial parks, backup power, photovoltaic storage, wind storage and other application scenarios to ensure the safety of industrial and commercial battery systems. Safe operation and system performance optimization.

Learn More

- What does the wireless communication base station inverter include

- What is the quota for adding panels to the grid-connected inverter of a communication base station

- What are the components of the grid-connected structure of the communication base station inverter

- Bangkok communication base station inverter grid-connected manufacturer

- Networking architecture of wireless communication base station inverter

- What is the battery capacity of base station communication equipment

- American communication base station inverter grid connection service provider

- Greece Small Communication Base Station Inverter

- Voltage level of 5g communication base station

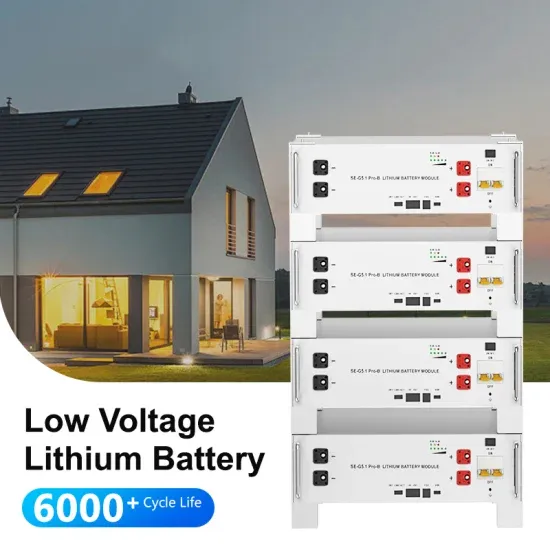

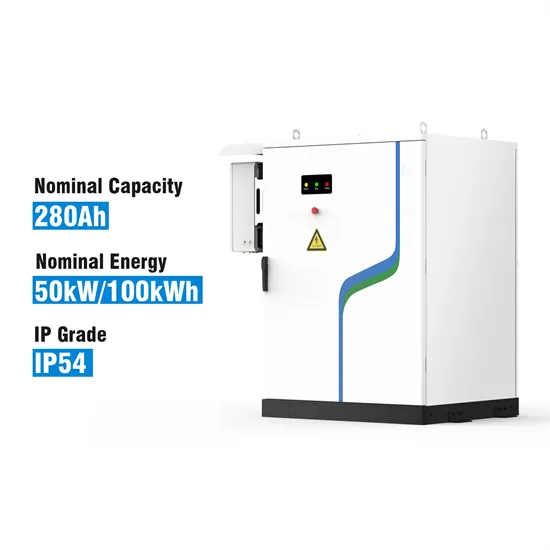

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.