How to connect 3 groups of 12v batteries in series

How to Connect 6 12V Batteries to Make 24V + Diagrams Divide the six batteries into three groups of two batteries each. Connect the batteries in each group in series: Connect the

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The production process of a lithium-ion battery cell consists of three critical stages: electrode manufacturing, cell assembly, and cell finishing.

Everything About Lithium Battery Series & Parallel

May 21, 2025 · Taking four groups of 12V batteries as an example, when one group is disconnected, its protection board needs to withstand a voltage of 36V, which exceeds the

How to make a 12 volt lithium-ion battery pack?

Nov 14, 2024 · Building a 12V lithium-ion battery pack can be a rewarding DIY project, providing you with a reliable power source for various applications. To

How To Connect Batteries in Series and Parallel

Apr 11, 2025 · For a 24V 200Ah system using four 12V 100Ah batteries, create two series pairs (24V 100Ah each), then connect these pairs in parallel. This "series-parallel" setup balances

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · A lithium battery pack is a collection of individual lithium-ion or lithium-polymer cells grouped together to store and deliver electrical energy. These packs are widely used in

Automated assembly of Li-ion vehicle batteries: A feasibility study

Jan 1, 2020 · Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable

Issues with 3 groups of 12v batteries

Oct 2, 2023 · Our boat has a 12v 5Kw Quattro connected to 14 100Ah LiFePO4 batteries. The batteries are in three groups - two groups of five batteries and one group of four batteries.

Charging LiFePO4 Batteries In Parallel And Series

Oct 7, 2023 · In conclusion, you must have got all the information around lithium batteries and charging lithium phosphate batteries in parallel and series. While

Lithium‐based batteries, history, current status,

Oct 7, 2023 · The resulting voltage difference between the two redox reactions generates the output voltage of the battery. Importantly redox reactions in

Assemble Lithium Battery: Step-by-Step Guide, Tools,

Learn how to assemble a lithium battery by yourself with our step-by-step guide. Discover the essential tools, materials, and safety precautions needed for successful assembly. Our

Car Battery Types & Groups Sizes – Which Do

Jun 24, 2023 · Find Your Car Battery Size – Battery Council International (BCI) has an online database of car battery sizes and types for different vehicles.

12V, 100Ah Lithium-Ion Battery Teardown Comparison

Mar 15, 2024 · 12V, 100Ah Lithium-Ion Battery Teardown Comparison U.S. Battery Engineering conducted tear-down comparisons between our "Essential Li" 12V 100Ah lithium-ion battery

What is the assembly process of the 12v lithium battery?

The internal resistance and voltage of the battery cells are matched in groups to ensure that the internal resistance and voltage of all cells in the overall 12v electric fish lithium battery pack are

How to connect 3 groups of 12v batteries in series

Can a 12V battery be wired together? It''s particularly useful for wiring two 6V lead acid batteries, or four 3.2V lithium cells, to make a 12V battery. Series connections can also be used to wire

12v energy storage lithium battery assembly

How do I build a 12V battery pack? To build a 12V battery pack, you will need: 18650 Cells: At least three cells connected in series. Battery Management System (BMS): To protect against

4 x 100Ah Parallel Battery Bank layout and fusing. Comments

Oct 12, 2022 · My diagram and plans for creating a LiFePo4 12V 4 x 100Ah battery bank. I am choosing a flexible buss bar setup. I thought about a solid copper buss bar but I am concerned

How to Connect 4 Batteries in Series

Dec 13, 2023 · Connecting 4 batteries in series is a straightforward process that helps increase voltage for devices that require higher power. This method involves linking the positive

How to Wire 12V Batteries in Series & Parallel

Feb 10, 2023 · In this tutorial, I''ll show you step-by-step how to wire batteries in series and parallel, as well as how to combine the two to create series-parallel

How To Connect Batteries In Series and Parallel

Feb 25, 2025 · For example, our next image shows three 12v batteries in series to create a 36v 35 AH battery pack. For our last series example, below are four

3. Battery bank wiring

Aug 30, 2024 · When creating a lead-acid battery bank with a higher voltage, like 24 or 48V you will need to connect multiple 12V batteries in series. But there is one problem with connecting

3 series 4 parallel lithium battery pack diagram

BU-302: Series and Parallel Battery Configurations Figure 2 shows a battery pack with four 3.6V Li-ion cells in series, also known as 4S, to produce 14.4V nominal. In comparison, a six-cell

What''s Inside a 12V Battery? Understanding

Apr 30, 2025 · A battery cell is the smallest unit that stores and delivers electrical energy. Multiple cells are combined – either in series, parallel, or both – to

Electrical Myths, Part 3: Mixing Batteries of Different

Jul 30, 2019 · If you have 6V batteries though, you''ll probably want one capable of analyzing an individual 6V batteries. You can make do with a 12V tester, but to match batteries you''ll have

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Connecting multiple lithium batteries into a string of batteries allows us to build a battery bank with the potential to operate at an increased voltage, or with increased capacity

How to build a 12v Battery Pack using Li-ion

Jun 11, 2022 · Still, the monitoring and control functions are applied to individual cells or groups of cells known as modules in the whole battery pack assembly.

6 FAQs about [Assembly of four groups of three 12v lithium batteries]

What is a 12V lithium battery series system?

The 12V lithium battery series system requires stricter parameter matching and a higher specification protection system. When multiple 12V lithium batteries are connected in series, the total voltage increases rapidly, and the voltage resistance requirements for the protection board increase exponentially.

How to connect 3 12V batteries in series?

If your battery allows it, you can repeat the above steps to connect more batteries in series. You can wire three 12V batteries in series to create a 36V battery bank. Once again, just connect the negative terminal of your 2-battery series string to the positive terminal of the third battery.

What is lithium ion battery assembly?

Lithium-Ion Battery Assembly: Involves stacking layers of anodes, cathodes, and separators. Assembly techniques include winding for cylindrical cells and stacking for prismatic cells. Requires careful handling of liquid electrolytes during assembly. Lithium Polymer Battery Assembly:

Can a 12V battery be connected in series?

When creating a lead-acid battery bank with a higher voltage, like 24 or 48V you will need to connect multiple 12V batteries in series. But there is one problem with connecting batteries in series, and this is that batteries are not electrically identical. They have slight differences in internal resistance.

What is lithium battery series connection?

This article will answer your questions: Lithium battery series connection is to connect multiple batteries end to end, with the positive electrode connected to the negative electrode of the next battery, which can increase the total voltage without changing the capacity.

How to connect 12V lithium batteries in series?

To safely connect 12V lithium batteries in series, the following options should be considered: Customized high voltage protection board: 48V system requires a protection board with a voltage of at least 80V, and the MOSFET selection must match the total voltage.

Learn More

- Can a 16v lithium battery be connected to a 12v inverter

- Battery cabinet 81 batteries 3 groups

- Lithium battery 12v to 220v inverter

- Are lithium batteries safe in the Solomon Islands

- How many types of single cylindrical lithium batteries are there

- Are large cylindrical lithium batteries durable

- Should I buy lithium batteries with BMS

- Are Uruguayan lithium batteries safe

- Can lithium iron phosphate batteries store energy

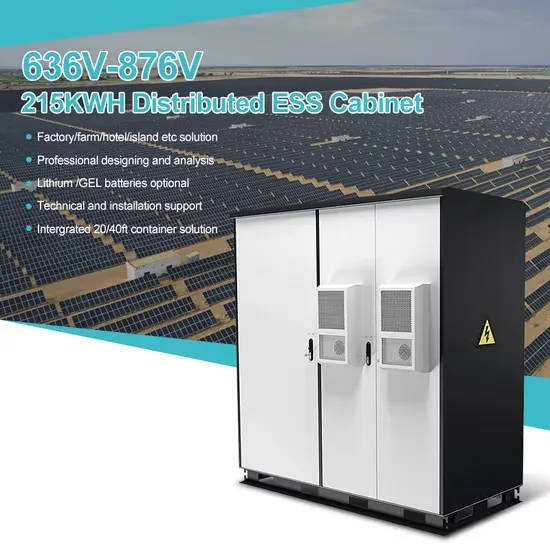

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

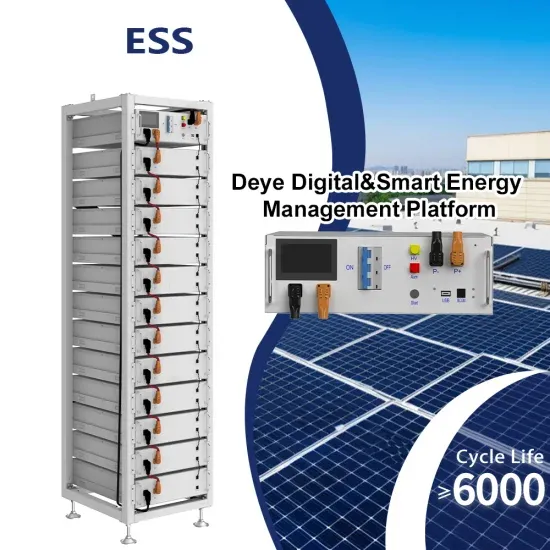

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.