Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

Cylindrical lithium battery: high capacity, safe and durable

Dec 31, 2021 · Why choose cylindrical lithium batteries? High capacity, safety and durability - learn about their advantages and how they provide reliable performance

Cylindrical vs. Prismatic Batteries: What You

Dec 3, 2024 · What are cylindrical batteries? Cylindrical batteries are lithium-ion cells shaped like cylinders, typically encased in a metal shell. The most

The best lithium cells for industry

Jan 23, 2020 · Cylindrical cells Cylindrical cells for lithium batteries are very similar to the batteries in our remote controls at hom e. The most common format is the 18650 cell (18mm diameter,

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Lithium Batteries: Cylindrical Versus Prismatic

Aug 6, 2019 · By and large, lithium batteries bring a wide range of different benefits to the table that are difficult - if not impossible - to replicate in any

How to enable large format 4680 cylindrical lithium-ion batteries

Nov 1, 2023 · The demand for large format lithium-ion batteries is increasing, because they can be integrated and controlled easier at a system level. However, increasing the size leads to

Large Cylindrical Battery Expand Ten Times More

May 22, 2025 · The fact that the volume change of large cylindrical battery far exceeds that of small cylindrical battery, with a difference exceeding tenfold.

What You Need to Know About Cylindrical Cells

May 20, 2025 · Cylindrical cells are a type of lithium-ion battery characterized by their cylindrical shape and robust metal casing. These cells play a key role in energy storage systems, offering

Cylindrical vs Prismatic Batteries: Everything Need to Know

Dec 3, 2024 · Cylindrical and prismatic batteries are two of the most common forms of lithium-ion batteries used today. Each type has distinct characteristics that make them suitable for

High-Level Dialogue in the Large Cylindrical Battery Sector:

Dec 17, 2024 · High-performance battery materials were emphasized as pivotal for enhancing performance and ensuring safety. On the production front, as large cylindrical battery

Everything You Need to Know About Cylindrical Batteries

Apr 24, 2025 · Cylindrical batteries can be categorized based on their filler materials into several types: lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganese oxide

Understanding Cylindrical Lithium-Ion Battery

Feb 19, 2025 · In today''s technology-driven world, cylindrical lithium-ion batteries are more than just a power source—they are a fundamental component in

Understanding Prismatic and Cylindrical Battery

May 9, 2025 · Compare prismatic and cylindrical battery cells, focusing on energy density, thermal management, and applications in EVs, energy storage, and

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · This study presented an electrochemical-thermal model for cylindrical lithium-ion batteries, integrating a detailed multi-layer thermal framework with electrochemical dynamics.

Advantages of Large Cylindrical Battery Cells

Mar 22, 2025 · Large cylindrical battery cells have gained significant attention in the energy storage and electric vehicle (EV) industries due to their unique design and performance

Understanding Prismatic and Cylindrical Battery Cell Designs

May 9, 2025 · Compare prismatic and cylindrical battery cells, focusing on energy density, thermal management, and applications in EVs, energy storage, and consumer electronics.

Analysis of Cylindrical Lithium Battery Advantages and

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

Size effect on the thermal and mechanical performance of cylindrical

Dec 1, 2024 · BYD and Godsend developed large-format cylindrical cell using LiFePo 4 (LFP) cathode, while this concept was initiated for LiNi x Co y Mn 1-x-y O 2 (NMC) cathode [9, 10].

What You Need to Know About Cylindrical Cells

May 20, 2025 · Cylindrical cells are robust lithium-ion batteries with high energy density, scalability, and durability, ideal for electric vehicles and energy storage systems.

How to Choose a Cylindrical Lithium Battery

Dec 17, 2024 · Cylindrical lithium batteries are compact, rechargeable, and durable, making them ideal for high-impact applications. They provide excellent thermal management, a long

Analysis of Cylindrical Lithium Battery Advantages and

2. The Development History of Cylindrical Lithium Batteries Since Tesla''s Battery Day in September 2020 introduced the 4680 large cylindrical cells, these cells have once again

6 FAQs about [Are large cylindrical lithium batteries durable ]

What is a cylindrical lithium battery?

The cylindrical battery shell has high voltage resistance and will not cause swelling of square or soft-packaged batteries during use. The cylindrical lithium battery cell size is larger. When the current is discharged, the internal temperature of the winding core is relatively high.

Are cylindrical lithium batteries a good choice?

Cylindrical lithium batteries are more suitable for large-volume automated combination production. Large-volume lithium-ion batteries such as electric bicycles and electric motorcycles are basically produced from cylindrical lithium batteries. Not only that, cylindrical lithium batteries are also recognized as green and healthy batteries.

What is a large cylindrical battery?

Large cylindrical batteries feature a steel casing with 550MPa strength—5.5 times that of prismatic aluminum casings (95MPa). Combined with a 1500MPa dual-layer hot-formed steel bottom design and 3500MPa aerospace-grade fiberglass, they achieve crash energy absorption of 1000J—6.6 times the national standard.

Why is a cylindrical lithium battery a bad battery?

The cylindrical lithium battery cell size is larger. When the current is discharged, the internal temperature of the winding core is relatively high. The activity at the edge of the cylindrical lithium battery pole piece is poor. Battery performance declines more obviously after long-term use.

What is the power density of a cylindrical lithium battery?

The rated energy density of a single cylindrical lithium battery is between 300 and 500Wh/kg. Its specific power can reach more than 100W. According to different models and specifications of cylindrical batteries, the actual performance of this type of battery varies. 3. Safety and reliability of cylindrical lithium batteries

Do cylindrical lithium-ion batteries increase energy density?

Increasing the size of cylindrical lithium-ion batteries (LIBs) to achieve higher energy densities and faster charging represents one effective tactics in nowadays battery society. A systematic understanding on the size effect of energy density, thermal and mechanical performance of cylindrical LIBs is of compelling need.

Learn More

- How many types of large cylindrical lithium batteries are there

- Do cylindrical lithium batteries need needle coke

- Cylindrical lithium batteries are safer

- Differences between different types of cylindrical lithium batteries

- How many types of single cylindrical lithium batteries are there

- Abkhazia How long is the life of cylindrical lithium batteries

- Chad cylindrical lithium battery customization

- Lithium battery cabinet cells and cylindrical cells

- Minimum dimensions of cylindrical lithium battery

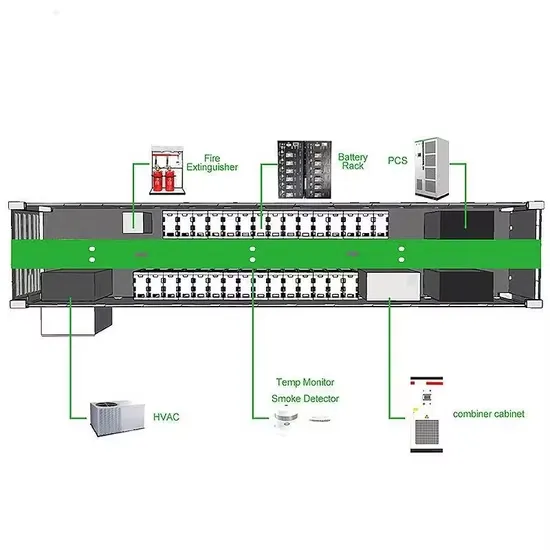

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.