Why Choose Cylindrical Batteries For EVs?

Apr 28, 2025 · Cylindrical batteries dominate EV applications due to their high energy density, robust thermal management, and manufacturing scalability. Their standardized design enables

Cylindrical vs. Prismatic Cells: Applications, Benefits, and

Introduction Cylindrical cells are a staple in the battery world, recognized for their robust design and widespread use across various applications. From powering everyday electronics to

Which Drone Battery Type Is Safer: Soft Pack or Cylindrical?

Advantages of Soft Pack Lithium Batteries Soft pack lithium batteries have many features that make them safer for drones. Their pouch-like design lets the cells expand and shrink during

Cylindrical vs. Prismatic vs. Li-Po Battery: Key

Feb 29, 2024 · Curious about battery types? Learn how cylindrical, prismatic, and lithium polymer batteries stack up against each other. Make the best choice!

Cylindrical Or Prismatic Cells Which is Best

Oct 11, 2022 · Cylindrical or prismatic cells? Which is the best option? When it comes to lithium batteries, there are 3 physical formats. There are cylindrical

Which battery is safer? cylindrical lithium battery or soft pack

Dec 2, 2019 · Is cylindrical lithium battery safer or soft pack lithium battery safer? As the best packaging method for the safety and performance of lithium-ion batteries, although the soft

Cylindrical Vs Pouch: Which Battery Is Safer?

May 18, 2025 · Cylindrical Vs Pouch: Which Battery Is Safer? Pouch batteries generally offer superior safety due to their aluminum-laminated film casing, which deforms safely during

BAK Large Cylindrical Batteries: Powering Safer, Smarter E

Jul 22, 2025 · BAK Battery unveils its full-tab cylindrical cell tech & diverse product matrix targeting e-bike safety, performance & cost needs at recent industry summit.

Mitigation of cylindrical lithium ion battery thermal runaway

The mesh includes the 25 NCA 18650 lithium ion batteries, the ceramic fiber insulation materials, the SABIC® PPcompound H1030 thermal barrier, and the free-stream space on top and side

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Prismatic VS Cylindrical Cells, What Is The

Aug 19, 2025 · Conclusion: Prismatic and cylindrical cells represent two distinct approaches to lithium-ion battery design. Each has its own set of advantages

Which battery is safer? cylindrical lithium battery or soft pack

Sep 27, 2024 · Is cylindrical lithium battery safer or soft pack lithium battery safer? As the best packaging method for the safety and performance of lithium-ion batteries, although the soft

Cylindrical Battery vs Prismatic Battery: Unveiling

Apr 18, 2025 · Cylindrical batteries are commonly used in high-performance electric vehicles, while prismatic batteries may be preferred for smaller or

Analysis of Cylindrical Lithium Battery Advantages and

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

6 Main Types of Lithium-Ion Batteries: Features,

Mar 8, 2025 · Explore the six main types of lithium-ion batteries, their key features, advantages, and ideal applications. Learn which battery type suits

A Quick Guide to Lithium-Ion Battery Sizes and

Apr 27, 2025 · Understand lithium-ion battery sizes like 18650, 14500, and pouch cells, and their applications in gadgets, EVs, and energy storage systems in

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes.

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Batteries A lithium-ion battery contains one or more lithium cells that are electrically connected. Like all batteries, lithium battery cells contain a positive electrode, a

V4Smart Introduces Generation 2 cells: A Breakthrough in

Aug 15, 2025 · V4Smart Introduces Generation 2 cells: A Breakthrough in High-Energy, High-Power Cylindrical Cells V4Smart GmbH s Co. KG, formerly known as V4Drive Battery GmbH,

Safer operating areas (SOA) of cylindrical lithium-ion battery

Oct 1, 2024 · This study introduces a real-time probabilistic safety assessment of a 18650 cylindrical battery. The physics-based failure scenarios from battery abu

Dynamic failure mechanisms of cylindrical lithium-ion batteries

Aug 1, 2025 · The development of lithium-ion batteries (LIBs) has been constrained by impact safety concerns. This study aims to provide novel failure mechanisms of

Safer operating areas (SOA) of cylindrical lithium-ion battery

Oct 1, 2024 · In culmination, a safer operating area (SOA) is proposed, leveraging the identified thresholds and most sensitive parameters. The proposed SOA with 4 distinct boundaries is not

Circular Battery vs Cylindrical Battery: Find the Right Fit

Feb 20, 2025 · Circular and cylindrical batteries differ in characteristics and applications. This article helps you choose the right one for optimal performance.

Lithium-ion Batteries are Safer Than Ever. That''s not Enough.

Jun 26, 2024 · Despite these challenges, safety advancements have greatly improved, with the failure rates of the most common cylindrical lithium-ion cells decreasing from 1 in 200,000 to 1

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

6 FAQs about [Cylindrical lithium batteries are safer]

Are cylindrical lithium-ion batteries safe?

Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes. This study conducts a design and process failure mode and effect analysis (DFMEA and PFMEA) for the design and manufacturing of cylindrical lithium-ion batteries, with a focus on battery safety. 1.

Are lithium ion batteries safe?

Major safety concerns for lithium-ion batteries are thermal runaway and explosion. Thermal runaway is a phenomenon where exothermic reactions occur within the cell, leading to a rapid temperature increase, potentially causing the cell to catch fire .

Which cylindrical lithium-ion batteries have the worst consequences?

Among all types of cylindrical lithium-ion batteries, the 21700 exhibits the worst consequence, which is attributed to the adoption of high energy density LiNi 0.8 Co 0.15 Al 0.05 O 2 (NCA) and LiNi x Mn y Co z O 2 (NMC) cathode materials.

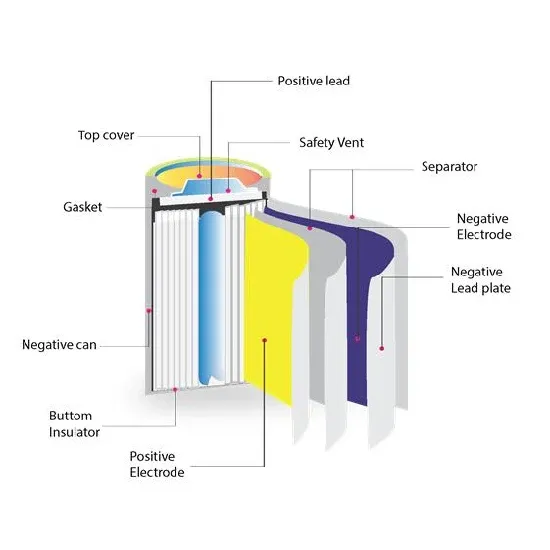

What is a cylindrical lithium ion battery?

Cylindrical batteries are composed of a rolled-up assembly called a jelly roll, which includes anode, cathode, and separator sheets tightly wound together and connected with electrical tabs. A schematic of a cylindrical lithium-ion battery is shown in Figure 2. Figure 2. Cylindrical battery structure.

Are lithium ion batteries flammable?

Some of these electrolytes are flammable liquids and requirements within OSHA’s Process Safety Management standard may apply to quantities exceeding 10,000 lb. Many of the chemicals used in lithium-ion battery manufacturing have been introduced relatively recently.

What is a lithium ion battery?

A lithium-ion battery contains one or more lithium cells that are electrically connected. Like all batteries, lithium battery cells contain a positive electrode, a negative electrode, a separator, and an electrolyte solution.

Learn More

- Are large cylindrical lithium batteries durable

- Abkhazia How long is the life of cylindrical lithium batteries

- How long is the life of American cylindrical lithium batteries

- Do cylindrical lithium batteries need needle coke

- Differences between different types of cylindrical lithium batteries

- How many types of large cylindrical lithium batteries are there

- Are there cylindrical lithium titanate batteries

- Are all Singapore lithium batteries cylindrical

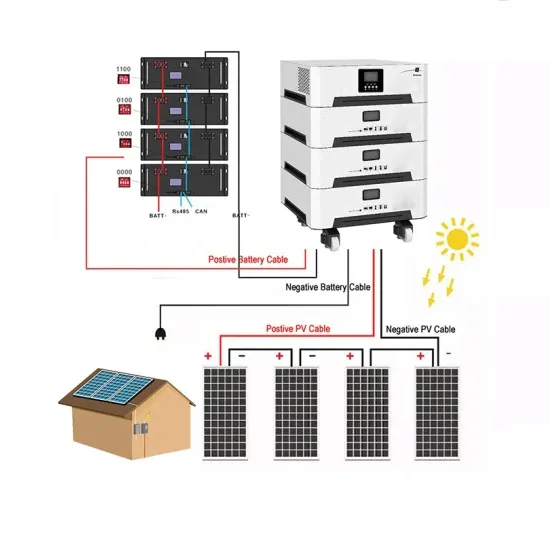

- Solar photovoltaic panels plus lithium batteries

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.