Needle Coke for EV Batteries Market

The global market size for needle coke used in EV batteries is projected to grow significantly from an estimated USD 1.5 billion in 2023 to an impressive USD 4.2 billion by 2032, exhibiting a

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium-ion cells are usually represented by five digits unting from the left,the first and second digits refer to the diameter of

Improved discharge capacities for lithium-ion batteries

Jan 29, 2024 · The rates and specific capacities of lithium-ion battery anodes are important factors used in evaluating the batteries. Needle coke is attracting attention as an anode material for

What You Need to Know About Cylindrical Cells

May 20, 2025 · Cylindrical cells are robust lithium-ion batteries with high energy density, scalability, and durability, ideal for electric vehicles and energy storage systems.

Structural Analysis of Needle Coke | Coke and Chemistry

Aug 27, 2019 · Abstract Industrial needle-coke samples from different producers are investigated by X‑ray diffraction and scanning electron microscopy. Their structural parameters La and Lc

Needle coke and synthetic graphite: Advance performance

Oct 31, 2024 · This article looks at the global graphite market and future demand. In turn, it details the author''s company''s proven delayed coking technology through conventional and two-step

Lithium Battery Anode Materials Needle Coke Market

Apr 6, 2025 · Lithium battery anodes require needle coke with ultra-high purity (sulfur content <0.5%, ash content <0.1%), optimal crystallinity, and uniform particle distribution to ensure

Global and China Needle Coke Industry Report, 2022-2027

Oct 21, 2022 · Abstract Needle coke that features low resistivity and strong resistance to impact and oxidation has found broad application in ultra-high-power graphite electrodes, nuclear

Spectroscopic graphite electrode needle-shaped Coke

May 5, 2019 · However, without needle-shaped Coke graphite, the battery energy density cannot be raised, and the battery quality will have problems. Most negative material manufacturers

Comparative study of the carbonization process and structural evolution

Jun 1, 2021 · Abstract To explore the carbonization behavior and structural evolution of needle coke prepared from different types of rich-aromatic materials, petroleum feedstock

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Improved discharge capacities for lithium-ion batteries

Jan 29, 2024 · Needle coke is attracting attention as an anode material for lithium-ion batteries due to its high reaction rates, but its low specific capacity still remains a problem to be solved.

Lithium Battery Uncalcined Needle Coke Market

Uncalcined needle coke is critical for manufacturing graphite anodes, a core component of lithium-ion batteries. Every 1 GWh of battery capacity requires **1,200–1,500 metric tons of anode

Technology of Petroleum Needle Coke Production in

1. INTRODUCTION Needle coke is a strategically important, highly structured carbon material obtained as a result of thermal degradation processing of highly fragranced petroleum

The role of petroleum coke in the negative

Jul 27, 2023 · Artificial graphite negative electrode material is a material with a certain particle size distribution obtained by crushing and granulating raw

Navigating Needle Coke for Anode Materials for Li-ion Battery

May 18, 2025 · The global market for needle coke used in anode materials for lithium-ion batteries is experiencing robust growth, projected to reach $1160 million in 2025 and expand

Improved electrochemical properties of lithium-ion batteries

Dec 1, 2024 · Oxygen plasma treatment enhanced needle cokes-based LIBs rate and specific capacities simply. High-rate capacities and specific capacities are important indicators for

Enhanced electrochemical performance of N, F co-doped and etched needle

May 20, 2024 · NF 3 plasma treatments were used to improve the electrochemical properties of needle coke-based lithium-ion battery (LIB) anode materials. The effects of the NF 3 plasma

Preparation of needle coke from low-temperature coal tar

Nov 1, 2024 · With the development of the new energy industry, needle coke is widely used in the fields of high-power graphite electrodes, ultra-high-power graphite electrodes, high-end carbon

Lithium Battery Anode Materials Needle Coke Market

Apr 6, 2025 · A 2023 survey of 150 lithium battery supply chain investors revealed that 68% would reject funding for needle coke facilities lacking ISO 14001 environmental certification. This has

Needle coke demand growth to tighten anode coke

Rising lithium-ion battery production is set to significantly raise demand for needle and ultra-low-sulphur petroleum coke in the coming years, pressuring supply of anode-grade petroleum

Methods for modifying needle coke raw materials by

Feb 15, 2022 · This discovery gave an impetus to the study of needle coke, which is widely used in metallurgy [2], namely by the steel and aluminium [3], [4], [5] industries in the production of

How to Clean a Car Battery with Coke

Apr 3, 2025 · Cleaning a car battery with Coke is an effective and affordable method to remove corrosion from the battery terminals. The phosphoric acid in Coke helps break down the rust

Electrochemical Performance of Coal-Based

Sep 27, 2024 · In this work, we have utilized needle cokes, an commercial carbon material with high carbon content and soft carbon structure, as a single carbon

Sustainable production of graphene from petroleum coke

Aug 23, 2021 · However, these numbers are based on the demand for needle coke for the steel and lithium-ion battery industries; needle coke production can be significantly increased to

Effect of coke orientation on the electrochemical properties of lithium

Jun 3, 2021 · In the present study, regular coke and needle coke, which exhibit different crystallinity and orientation, were graphitized to investigate the lithium-ion storage mechanism

Production of needle cokes via mild condition co-pyrolysis of FCC-DO

Mar 15, 2024 · The conventional needle coke production process suffers from high reaction temperature and pressure, and therefore, alternative approaches for needle coke production

Silicon/Needle Coke Composites as Efficient Anodes for

It was found that Si nanosheets adhered to needle cokes forming silicon/carbon composites. Compared with needle cokes, the composites showed higher capacity and initial coulombic

6 FAQs about [Do cylindrical lithium batteries need needle coke ]

Why is needle coke a good anode material for lithium-ion batteries?

The rates and specific capacities of lithium-ion battery anodes are important factors used in evaluating the batteries. Needle coke is attracting attention as an anode material for lithium-ion batteries due to its high reaction rates, but its low specific capacity still remains a problem to be solved.

Does oxygen plasma treatment improve the electrochemical properties of needle Cokes-based lithium-ion batteries?

Oxygen plasma treatment enhanced needle cokes-based LIBs rate and specific capacities simply. High-rate capacities and specific capacities are important indicators for evaluating lithium-ion battery (LIB) anodes. To improve the electrochemical properties of needle coke-based anode materials, oxygen plasma treatment was used.

Can ozone treatment improve the discharge capacity of needle coke-based anodes?

Needle coke is attracting attention as an anode material for lithium-ion batteries due to its high reaction rates, but its low specific capacity still remains a problem to be solved. In this study, we attempted to improve the discharge capacity of needle coke-based anodes by introducing oxygen into the needle coke with ozone treatments.

Can ozonation increase the capacity of a needle coke battery?

Needle coke-based lithium-ion batteries with oxygen introduced through ozone treatment showed capacity increases of up to 17.4% and retention rates of 64.25% at 5 C. Therefore, introducing oxygen functional groups into needle cokes through ozonation is a viable strategy for producing rapid and high-capacity anode materials.

Are NF 3 plasma needle Cokes a fast charging anode material?

The NF 3 plasma treatment was identified as an effective way to improve the specific capacities, rates, and cycling stabilities of LIB anode materials; therefore, NF 3 plasma needle cokes have become fast charging anode materials with high stabilities and competitive capacities. 3.3. Mechanistic analyses

Are needle Cokes a good carbon material?

Celzard et al. investigated the high conductivity of needle cokes (331.7 S/cm); this conductivity was significantly greater than those of natural graphite (197.0 S/cm) and artificial graphite (106.5 S/cm) . Therefore, needle cokes are considered attractive carbon materials.

Learn More

- How many types of single cylindrical lithium batteries are there

- Cylindrical lithium batteries are safer

- Abkhazia How long is the life of cylindrical lithium batteries

- How long is the life of American cylindrical lithium batteries

- Are large cylindrical lithium batteries durable

- What are the types of cylindrical lithium batteries

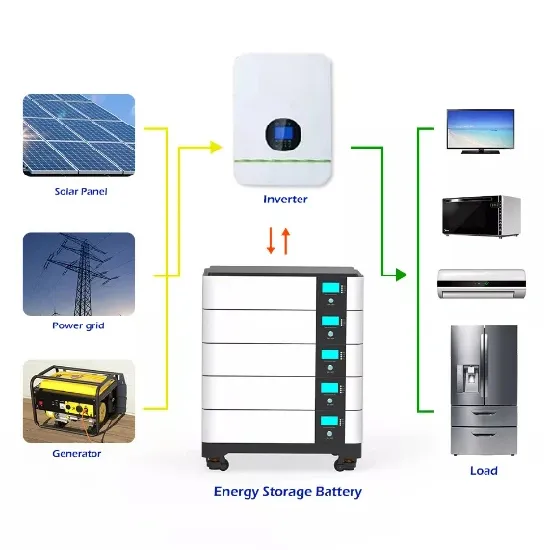

- Lithium batteries for energy storage systems

- Ghana bans lithium batteries for energy storage

- Can the electricity generated by photovoltaic panels be directly connected to lithium batteries

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.