Smart Battery Systems

Apr 11, 2016 · Technology Leadership Samsung SDI having 6,645 patents in total leads future business energy market based on world-class technology leadership. As a lithium-ion battery

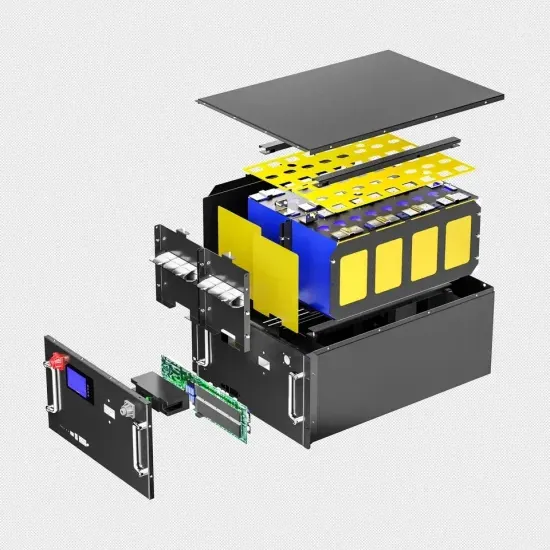

ABS Cabinet Box (Enclosure/Box) for DIY Lithium Battery

Introducing the ABS Cabinet (Enclosure) for Lithium Battery Pack, a robust and reliable solution for housing your lithium-ion battery cells. Designed to accommodate 12V/30AH or 24V/15AH

Manufacturing of tabless cylindrical lithium-ion cells:

Sep 15, 2024 · The authors thank cell manufacturer BAK Battery for providing important insight and participating in valuable scientific discussion about all aspects of manufacturing for

What Are Cylindrical Battery Cells and Their Role in Energy

Feb 21, 2025 · Cylindrical battery cells are a type of electrochemical cell characterized by their round shape and uniform dimensions. They are widely used in various applications, including

Lithium Ion Battery Assembly Process and Line: Cylindrical vs

Aug 20, 2024 · Cylindrical Cell Assembly Process The assembly of cylindrical cells, commonly used in electric vehicles and portable electronics, involves several critical steps: 1. Jelly Roll

What You Need to Know About Cylindrical Cells

May 20, 2025 · Cylindrical cells are robust lithium-ion batteries with high energy density, scalability, and durability, ideal for electric vehicles and energy storage systems.

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Comparatively Assessing different Shapes of Lithium-ion Battery Cells

Jan 1, 2017 · Different shapes of lithium-ion batteries (LIB) are competing as energy storages for the automobile application. The shapes can be divided into cylindrical and prismatic, whereas

Lithium Prismatic Cells vs Cylindrical Cells: Pros

Apr 13, 2023 · Two common types of shapes are prismatic cells and cylindrical cells. Both offer specific qualities to the application, whether you are looking

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Cylindrical battery pack – design and structure

Jul 8, 2023 · Basic structure of cylindrical battery pack In the cylindrical battery pack design, the battery pack structure is various. It is mainly determined

Best practices in lithium battery cell preparation and

Dec 4, 2023 · Aside from studies and developments of traditional LIBs based on lithium (Li) intercalation between the graphite anode and lithium transition metal oxide cathode, Li metal

Lithium-ion Battery Safety

Jan 13, 2025 · There are several types of lithium cells, including cylindrical cells, prismatic pouch cells, and prismatic metal can cells. Lithium-ion batteries use lithium in ionic form instead of in

The Three Major Li-ion Battery Form Factors:

Oct 14, 2020 · One of the most recent developments in this field came from Tesla Battery Day with a tabless battery cell Elon Musk called a "breakthrough" in

HANDBOOK Primary Lithium Cells (english)

1. general information the Varta microbattery lithium manganese dioxide cell chemistry was one of the first solid cathode cells commercially developed and is still the most widely used system

LITHIUM CELL FORM FACTOR CYLINDRICAL LITHIUM

Mar 25, 2021 · LITHIUM CELL FORM FACTOR individual cells and a circuit board of some kind. There are three types of cells that are used in lithium bat eries – cylindrical, prismatic, and

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · When choosing a lithium battery for your RV, marine vessel, or off-grid application, it''s critical to understand the three main cell formats. Each cell type brings unique advantages

6 FAQs about [Lithium battery cabinet cells and cylindrical cells]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

What is a cylindrical lithium cell?

ePO4) and 3.2 volts (V).CYLINDRICAL LITHIUM CELLSA cylindrical cell looks most like what you think of with a traditional household battery – like an AA battery – and that is exactly where this form factor drew it’s inspiration for sha e when they first came to market in the mid-1990s. Cylindrical lithium cells come in different widths and lengt

What is the difference between a cylindrical and a prismatic Lithium battery?

Due to the round shape, the packing density of electrically connected cylindrical LIB is lower than the packing density of prismatic LIB. In terms of safety, the housing stability of the cylindrical and the hard-case cell is considerably higher than the pouch cell housing, which requires additional housing stability as part of a battery system.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

Learn More

- How long can the lithium iron phosphate battery of the energy storage cabinet be used

- Customized price of outdoor lithium battery station cabinet

- Tajikistan lithium iron phosphate battery EK cylindrical

- Embedded cylindrical lithium battery

- Xiaomi energy storage cabinet does not require lithium battery charging

- Tunisian cylindrical lithium battery

- Nepal lithium battery station cabinet custom price inquiry

- Energy storage cabinet lithium battery franchise

- Huawei cylindrical lithium battery cell

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.