Decoupling the influence of impact energy and velocity on

Dec 30, 2024 · The findings highlight that different factors dominate battery failure under varying impact velocities. This research enhances understanding of the energy- and velocity

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The importance of cylindrical batteries is only growing because they are used widely from small electronic devices to EVs. In line with the

Enhanced Thermal Regulation of Lithium-Ion Batteries Using

Feb 21, 2025 · Abstract. Poor thermal conductivity is common in batteries that use phase change material (PCM)-based thermal management systems (BTMS). This study introduces cylindrical

Battery Options For Embedded Applications

Oct 25, 2010 · Another type growing in popularity is the Energizer Ultimate Lithium AA and AAA. Energizer introduced these 1.5V lithium cylindrical batteries over 15 years ago.

Cooling performance of a Li-ion cylindrical battery pack with

May 15, 2024 · Lithium-ion batteries are widely used as power sources and a battery thermal management system (BTMS) is needed to ensure that the battery operates within the optimal

In-situ temperature monitoring of a lithium-ion battery

Oct 17, 2023 · Keywords: Lithium-ion battery Cell instrumentation Embedded sensing In-situ monitoring Internal temperature Cell performance Battery ageing

In-situ measurement of internal gas pressure within cylindrical lithium

Jun 30, 2023 · Internal gas pressure is a key parameter that varies depending on cell heating and gas formation over the lifetime of a lithium-ion cell under dynamic load conditions and ageing.

Design and Simulation Analysis of Thermal Management for Cylindrical

Oct 27, 2024 · A cooling system featuring an immersed liquid-cooled honeycomb structure was developed for cylindrical lithium-ion power batteries. COMSOL simulation software w

An Integrated Flow–Electric–Thermal Model for a

Jun 27, 2022 · An integrated model is constructed for a Li-ion battery module composed of cylindrical cells by coupling individual first-order equivalent circuit

锂离子电池植入传感技术

Nov 6, 2022 · 单体层级植入传感技术,可获得全寿命周期单体内部温度场、应变场、气压、气体等多传感信息,有望实现早预警、早隔离、早处置。 本文将系

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

In-situ measurement of internal gas pressure within

Apr 21, 2023 · Internal gas pressure is a key parameter that varies depending on cell heating and gas formation over the lifetime of a lithium-ion cell under dynamic load conditions and ageing.

Dynamic response analysis of cylindrical lithium-ion battery

Dec 1, 2024 · The prediction of serious deformation for lithium-ion batteries (LIBs) under impact loadings becomes an important challenge for engineering application. In this paper, a

Future smart battery and management: Advanced sensing from external

Mar 31, 2021 · Lithium-ion batteries (LIBs) has seen widespread applications in a variety of fields like the renewable penetration, electrified transportation, and portable electronics. A reliable

Investigation on enhancing thermal performance of the Li-ion battery

Jan 15, 2025 · To meet the escalating demand for high energy and power diversity in EVs, a battery pack comprising 72 single cylindrical Li-ion batteries is proposed, as illustrated in Fig. 1.

A Compact Hybrid Battery Thermal Management System

Dec 3, 2024 · Abstract Hybrid battery thermal management systems (HBTMS) combining active liquid cooling and passive phase change materials (PCM) cooling have shown a potential for

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · This paper is a comprehensive numerical investigation of the optimization of thermal management systems of lithium-ion batteries (LIBs) through the synergistic integration

Dynamic crushing behaviors and failure of cylindrical lithium

Dec 1, 2023 · The mechanical property and failure prediction play a significant role in engineering applications of lithium-ion batteries (LIBs), but with great difficulties due to their complicated

A novel embedded method for in-situ measuring internal

Apr 30, 2020 · A novel embedded method for in-situ measuring internal multi-point temperatures of lithium ion batteries Shengxin Zhu a b, Jindong Han a b, Hong-Yan An a b, Tai-Song Pan

Design of a PCM-based thermal management system for cylindrical Li

Jul 1, 2025 · The authors in their work conducted experiments on a fin-enhanced PCM-based BTMS for a cylindrical Li-ion cell and recorded the average battery temperature–time histories.

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · This paper is a comprehensive numerical investigation of the optimization of thermal management systems of lithium-ion batteries (LIBs) through the synergi

Optimization of a phase change material based internal

Sep 15, 2017 · An effective and compact thermal management system is essential for modern lithium-ion (Li-ion) battery powered vehicles, which involve rigorous constraints on weight and

Operando monitoring of internal gas pressure in commercial lithium

Oct 1, 2023 · The electrode material volume constantly fluctuates with lithiation and delithiation during the operation of Li-ion batteries, resulting in a change in the internal gas pressure.

Thermal performance of a hybrid thermal management

Battery thermal management systems (BTMS) are crucial for ensuring the safety and performance of Lithium-ion batteries (LIBs). This study proposes a novel hybrid BTMS that integrates phase

Direct cooling thermal management of cylindrical batteries

Apr 9, 2025 · For lithium-ion batteries, excessive temperature and nonuniform thermal distribution reduce stability, shorten service life, and may even lead to thermal runaway. To mitigate these

Thermal performance of honeycomb-like battery thermal management system

Apr 1, 2021 · Thermal performance of honeycomb-like battery thermal management system with bionic liquid mini-channel and phase change materials for cylindrical lithium-ion battery

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Sim-YOLOv5s: A method for detecting defects on the end face of lithium

Jan 1, 2023 · The detection of lithium battery shell defects is an important aspect of lithium battery production. The presence of pits, R-angle injuries, hard printing, and other defects on the end

Liquid cooling with phase change materials for cylindrical Li

Jan 15, 2020 · In this study, we design a hybrid thermal management system that combines liquid cooling and phase change materials (PCMs) for a battery pack of 20 Li-ion cylindrical cells.

6 FAQs about [Embedded cylindrical lithium battery]

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

Why are cylindrical lithium-ion batteries used in electric vehicles?

This study is particularly significant because cylindrical lithium-ion batteries are widely used in electric vehicles due to their high energy density and mechanical robustness. Various fin configurations are analyzed to optimize heat dissipation, effectively reducing peak temperatures during high discharge operations.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

Do cylindrical lithium-ion batteries have a thermal stability problem?

This work is motivated by the critical need to improve the thermal stability of cylindrical lithium-ion batteries, especially in electric vehicles and high-performance electronics, where overheating during rapid charging and high discharge rates can lead to thermal runaway and decreased lifespan.

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

What is a cylinder Li-ion battery?

Cylindrical Li-ion battery cells consist of (i) a jelly roll, a wound composite consisting of a cathode, an anode, and two separators, and (ii) a cell housing consisting of a can and a cap . Current and heat transport between the jelly roll and the cell housing is traditionally conducted by contacting elements called tabs .

Learn More

- Ethiopia cylindrical lithium battery

- Lithium battery 3 6v cylindrical double

- Dili Large Cylindrical Lithium Battery

- How many volts is the largest cylindrical lithium battery in Albania

- What kind of cylindrical lithium battery is it

- Cylindrical lithium battery diameter 25 height 65

- Is the Warsaw lithium battery cylindrical

- Tbilisi cylindrical lithium battery equipment

- Venezuelan cylindrical lithium battery milliwatt normal

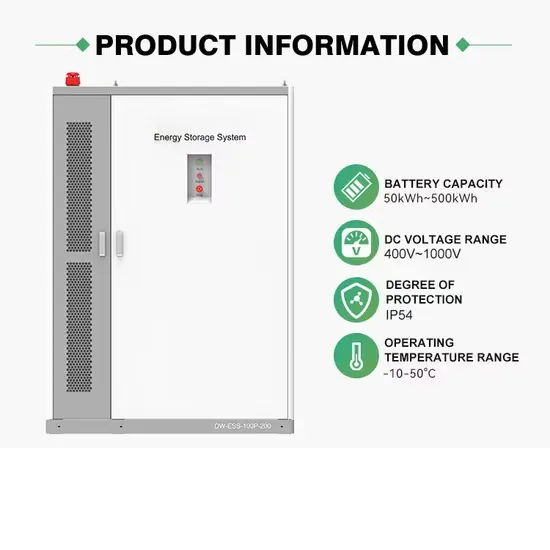

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.