【New message】Innovative Polymer Battery Solutions

Cylindrical lithium batteries are rechargeable power cells characterized by their distinctive cylindrical shape, typically encased in a durable metal shell. This form factor offers excellent

EVE Energy and Germany''s KBS sign strategic supply

Apr 10, 2025 · By providing zero-carbon power solutions for high-end European logistics equipment, the two parties will jointly build an industrial ecosystem covering technology R&D,

Lithium battery discharge equipment manufacturer in Tbilisi

The discharge is a discharge device for a lithium-ion battery module, including a cabinet, a discharge control cabinet, an energy consumption box, and a hot air exhaust mechanism. The

Tbilisi energy storage lithium battery shell

How safe is a cylindrical lithium-ion battery? The cylindrical lithium-ion battery has been widely used in 3C, xEVs, and energy storage applications and its safety sits as one of the primary

Cylindrical lithium battery pilot line-Products-Hongmumian

division capacity ocv test Lithium battery safety testing equipment Battery Safety Test Equipment Series Battery environmental box test equipment Other non-standard special equipment

18V 5000mAh Medical Replacement Li-ion Battery M3539A Battery

18V 5000mAh Medical Replacement Li-ion Battery M3539A Battery For PHILIPS Power Supply Philips HeartStart MRx Defibrillator, Competible With M3539A, M3538A; Suitable for Philips

Cylindrical Lithium Battery Winding Equipment Market

Jul 23, 2025 · Global Cylindrical Lithium Battery Winding Equipment market was valued at USD 527M in 2024 and is projected to reach USD 1917M by 2032, at a 20.2% CAGR.

Tbilisi Hongtu Energy Storage Technology Company:

Sep 25, 2020 · When Chemistry Meets Chacha: Hongtu''s Tech Breakdown lithium-ion batteries that work harder than a Sulphur Springs bartender during tourist season. Hongtu''s modular

Cylindrical Cell manufacturing equipment

May 6, 2025 · Cylindrical cell manufacturing equipment is specialized for the production of cylindrical lithium-ion batteries, which are widely used in applications ranging from consumer

Cylindrical Battery Equipment – Lithium Battery Production Equipment

Whether you need high-quality glove boxes, precision-engineered vacuum chambers, or customized equipment tailored to your industry, we''ve got you covered. Request a quote or

Tbilisi New Energy Battery Cell Factory Address

Subaru and Panasonic Energy to Begin Preparation for As part of this collaboration, Panasonic Energy will produce and supply cylindrical lithium-ion batteries at its Suminoe factory in Osaka

Tbilisi micro energy storage spot welder

In an automotive battery pack, many Li-ion cells are connected to meet the energy and power requirement. The micro-resistance spot welding (micro-RSW) process is one of the commonly

Tbilisi cylindrical lithium battery equipment

Lithium-ion battery automatic production equipment includes lithium-ion battery sticking barley paper, lithium-ion battery Sorting Machine, lithium-ion battery welding machine, lithium-ion

tbilisi energy storage lithium battery shell

Lithium–antimony–lead liquid metal battery for grid-level energy storage | Nature Here we describe a lithium–antimony–lead liquid metal battery that potentially meets the performance

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

how is the tbilisi energy storage container

Battery-Based Energy Storage: Our Projects and Achievements The battery-based ESS facility at the Carling platform came on stream in May 2022 and comprises 11 battery containers. The

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

Cylindrical Lithium Battery Production Line: Fully Automated Equipment

Discover our advanced cylindrical lithium battery production line designed for manufacturing 18650, 21700, and other cylindrical battery models. Our fully automated equipment covers

Learn More

- Tbilisi cylindrical lithium battery manufacturer

- Liechtenstein cylindrical lithium battery equipment manufacturing

- What equipment is needed to make lithium battery pack

- What is a dual-cell cylindrical lithium battery

- Tunisian cylindrical lithium battery

- Syria cylindrical lithium iron phosphate battery

- Ethiopia cylindrical lithium battery

- How many volts is the largest cylindrical lithium battery in Albania

- Capacity cylindrical lithium battery

Industrial & Commercial Energy Storage Market Growth

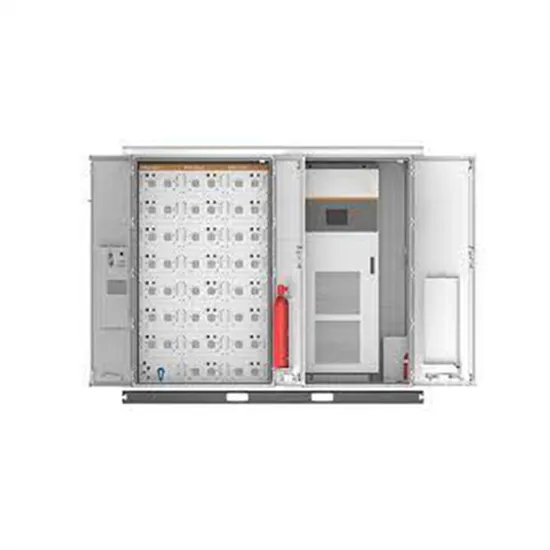

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.