Battery Manufacturing | Bosch Manufacturing Solutions | BMG

5 days ago · With over 15 years of experience in battery manufacturing, we specialize in Cell to Pack Manufacturing and Cell Technology solutions for battery modules and packs. Our

【New message】Innovative Polymer Battery Solutions

Choose GeB for expertly engineered cylindrical lithium batteries that precisely meet your specifications. In a world increasingly reliant on advanced energy storage, the demand for

(PDF) Lithium-ion Battery Cell Production

Feb 6, 2019 · Abstract The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium

Liechtenstein Group invests in TESVOLT

Jul 21, 2025 · State-of-the-art prismatic lithium battery cells from Samsung SDI combined with TESVOLT´s patented and TÜV-certified Active Battery Optimizer (ABO) smart cell control

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Lithium Cell Manufacturing Line

Dec 12, 2024 · Lithium Cell Manufacturing Line: Key to Efficient and Scalable Battery Production A lithium cell manufacturing line is a specialized production facility designed to manufacture

Cylindrical Cell Manufacturing Equipment Solutions | Targray

Aug 16, 2025 · Cylindrical Cell Manufacturing can be broken down into 4 stages: Electrode preparation, Cell assembly, Case formation & sealing, and battery testing.

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Battery manufacturing in Liechtenstein

State-of-the-art prismatic lithium battery cells from Samsung SDI combined with TESVOLT´s patented and TÜV-certified Active Battery Optimizer (ABO) smart cell control system are the

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Cylindrical Lithium Battery Production Line: Fully Automated Equipment

The cylindrical lithium battery production line is designed for manufacturing 18650, 21700, and other models of cylindrical lithium-ion batteries. This production line covers the entire process

Cylindrical battery laboratory manufacturing factory

Our cylindrical battery laboratory manufacturing factory is equipped with advanced equipment and technology for battery development, optimization, large-scale production testing, and validation.

Lithium Battery Production & Intelligent Equipment | Mikrouna

Founded in 1998, Mikrouna is a leading high-tech enterprise specializing in vacuum automation and intelligent equipment. Holding over 180 patents, Mikrouna offers isolated glove boxes,

Cylindrical Cell manufacturing equipment

May 6, 2025 · Cylindrical cell manufacturing equipment is specialized for the production of cylindrical lithium-ion batteries, which are widely used in applications ranging from consumer

Advanced lithium-ion battery process manufacturing equipment

Jul 18, 2025 · Manufacturing equipment evaluation highlights significant challenges in electrode preparation, cell assembly, and finishing. Using space-saving machinery and cost-effective,

LEAD Cylindrical Lithium Battery Manufacturing Turnkey

Common variants include cylindrical lithium-ion batteries and LFP cylindrical cells, which offer enhanced safety and longevity. LEAD delivers end-to-end lithium battery solutions for

6 FAQs about [Liechtenstein cylindrical lithium battery equipment manufacturing]

Which countries manufacture Li-ion batteries?

Manufacturing contributes about 25 percent of the cost of the Li-ion battery. China, Japan, and South Korea are the major manufacturers and suppliers of equipment for Li-ion cell production.

How can a battery production line be sustainable?

Innovations such as simultaneous cell formation processes, seen in companies like Tesla and Panasonic, exemplify how global manufacturers are optimizing battery production lines to meet the demands of electrification and sustainable energy storage worldwide. - Equipment manufacturing can rely on green production.

How can a local battery manufacturing system help a battery plant?

Local manufacturers will scale up and cover the entire machinery for a battery plant through collaborations, from producing electrodes to the final cell formation. Localizing innovation and equipment manufacturing will build a sustainable and competitive battery manufacturing system.

Are GWh-scale battery production systems a viable solution to the Lib demand surge?

Most of the developments in battery production target GWh–scale production systems to meet the global LIB demand surge, especially in EV and stationary storage applications.

How is a lithium ion battery made?

Lamination is a key technology for Lithium-ion battery production. The individual electrode and separator sheets are laminated onto each other in a continuous process and are then usually pressed together by a heat press, improving production line speed.

What are lithium-ion batteries used for?

In the rapidly evolving world of energy storage, lithium-ion batteries have become the dominant choice for applications ranging from electric vehicles (EVs) to portable electronics.

Learn More

- Tbilisi cylindrical lithium battery equipment

- Dili Large Cylindrical Lithium Battery

- Cylindrical 12v lithium battery

- Tunisian cylindrical lithium battery

- Syria cylindrical lithium iron phosphate battery

- Ethiopia cylindrical lithium battery

- What kind of cylindrical lithium battery is it

- Is the Warsaw lithium battery cylindrical

- Huawei Tokyo cylindrical lithium battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

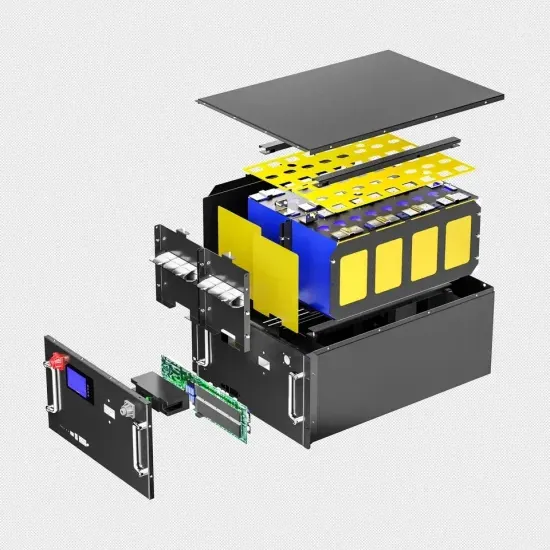

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.