Lithium phosphate battery for solar Solomon Islands

Wholesale Lithium-Ion Battery for PV Systems? Simply put, a lithium-ion battery (commonly referred to as a Li-ion battery or LIB) is a type of rechargeable battery that is commonly used

What is the current of the Solomon Islands lithium battery

single unit that contains a 48 Volt 200Ah Lithium Battery. Additionally, the battery uses the safest LiFePO4 electrochemical tech ology, so you can trust that it''''s reliable and efficient. Plus, the B

Are lithium batteries safe in the Solomon Islands

Lithium Batteries: Are They Safe? The anti-lithium folks say, basically, "Why risk it?" Lead-acid batteries have done the job for more than 160 years (Gaston Planté invented the rechargeable

LITHIUM BATTERIES MANUFACTURERS IN SOLOMON ISLANDS

Which battery is better alkaline or lithium? Lithium batteries have a higher energy density compared to alkaline batteries. This means that for the same size and weight, lithium batteries

Buy Battle Born BatteriesLithium-Ion (LiFePO4) Deep Cycle 12V Battery

Shop Battle Born BatteriesLithium-Ion (LiFePO4) Deep Cycle 12V Battery 100Ah – Safe & Powerful Drop-In Replacement for RV, Van, Marine, Off-Grid – Cylindrical Cells, Internal BMS

Solomon Islands latest lithium battery technical regulations

Designed by data center experts for data center users, the Vertiv™ HPL battery cabinet brings you cutting edge lithium-ion battery technology to provide compelling savings on total cost of

Is It Safe To Visit Solomon Islands? Discover The Truth

Apr 29, 2025 · The Solomon Islands, a breathtaking archipelago in the South Pacific, beckon travelers with their pristine beaches, vibrant coral reefs, and rich cultural heritage. However,

Lifepo4 Battery Solar Energy Storage Systems Lithium Batteries

Shop Lifepo4 Battery Solar Energy Storage Systems Lithium Batteries Pack 24V 48v 100ah 200ah Lifepo4 Lithium Battery for Solar Panel online at best prices at desertcart - the best

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to

Dangerous Goods | Airline Restrictions | Solomon Airlines

Security type attaché cases incorporating dangerous goods, such as lithium batteries or pyrotechnic devices are forbidden. Disabling devices such as mace, pepper spray etc.

Solomon Islands jinko lithium battery

Solomon Islands jinko lithium battery The Jinko 5kw Lithium Battery 48v 100Ah JKS-B51100-CI is a 5.12kWh lithium battery module from Jinko Solar. It is a 48V, 100Ah battery that is made with

Are lithium batteries safe in the Solomon Islands

When comparing battery safety, Lithium Iron Phosphate (LiFePO4) batteries are generally safer than Ternary Lithium (NMC) batteries. Ternary lithium battery Ternary lithium powerpack is

Solomon Islands Energy Storage Lithium Iron Phosphate Battery

Lithium Iron Phosphate (LFP) batteries feature robust thermal and chemical stability, providing safety advantages over other lithium-ion battery types. At the heart of these batteries lies

Battle Born Batteries Lithium-Ion (LiFePO4) Deep Cycle 12V Battery

Shop Battle Born Batteries Lithium-Ion (LiFePO4) Deep Cycle 12V Battery 100Ah – Safe & Powerful Drop-In Replacement for RV, Van, Marine, Off-Grid – Cylindrical Cells, Internal BMS

Lithium battery explosion in Solomon Islands

Lithium Batteries Selection Guide: Types, Features, Applications Lithium manganese dioxide (Li-Mn) and lithium thionyl chloride are two types of primary lithium batteries. Li-Mn batteries

Lithium Battery Production Safety Inspection Regulations

Key regulations governing lithium batteries include: UN 38.3: This regulation outlines testing requirements for the safe transport of lithium batteries. IEC 62133: This standard specifies

Solomon Islands lithium ion battery renewable energy

The project will support the Solomon Islands government to boost renewable energy generation and increase access to grid-supplied electricity, while reducing reliance on expensive,

SOLOMON ISLANDS LITHIUM PRODUCTION

These include performance and durability requirements for industrial batteries, electric vehicle (EV) batteries, and light means of transport (LMT) batteries; safety standards for stationary

Lithium Battery Production Safety Inspection Regulations

New EU regulatory framework for batteries Batteries contain a wide variety of materials, such as base metals, critical raw materials and chemicals, which can raise issues in terms of resource

Cellec Technologies awarded $100,000 NSF SuperBoost

Funding from the NSF Energy Storage Engine in Upstate New York to accelerate next-generation battery safety and performance for electric vehicles, aerospace, and defense ROCHESTER,

6 FAQs about [Are lithium batteries safe in the Solomon Islands ]

Are lithium-ion solar batteries safe in South Africa?

Lithium-ion Solar Batteries have become very popular in South Africa for being reliable, safe and having a longer life span than Lead-Acid batteries. While it may seem daunting right now, our lithium solar battery guide will help you see the light – pun intended!

What is a lithium ion battery?

A lithium-ion battery contains one or more lithium cells that are electrically connected. Like all batteries, lithium battery cells contain a positive electrode, a negative electrode, a separator, and an electrolyte solution.

Are lithium ion batteries flammable?

Some of these electrolytes are flammable liquids and requirements within OSHA’s Process Safety Management standard may apply to quantities exceeding 10,000 lb. Many of the chemicals used in lithium-ion battery manufacturing have been introduced relatively recently.

What are lithium ion batteries used for?

They power devices such as mobile telephones, laptop computers, tablets, cameras, power tools, electric vehicles, and machinery, and are also used in large Energy Storage Systems (ESS). Lithium-ion batteries may present several health and safety hazards during manufacturing, use, emergency response, disposal, and recycling.

Are lithium ion batteries dangerous?

Lithium-ion batteries contain various components that present different chemical hazards to workers, such as lammability, toxicity, corrosivity, and reactivity hazards. These chemicals may enter the workplace as raw materials or recycled materials.

What are the OSHA standards for lithium-ion batteries?

While there is not a specific OSHA standard for lithium-ion batteries, many of the OSHA general industry standards may apply, as well as the General Duty Clause (Section 5(a)(1) of the Occupational Safety and Health Act of 1970). These include, but are not limited to the following standards:

Learn More

- Are photovoltaic energy storage lithium batteries safe

- Solomon Islands Power Tool Lithium Battery

- Are Uruguayan lithium batteries safe

- How many cells are needed to charge tool lithium batteries

- How many types of single cylindrical lithium batteries are there

- Do cylindrical lithium batteries need needle coke

- Lithium batteries and energy storage devices

- BMS for lithium batteries

- Cook Islands cylindrical lithium battery factory

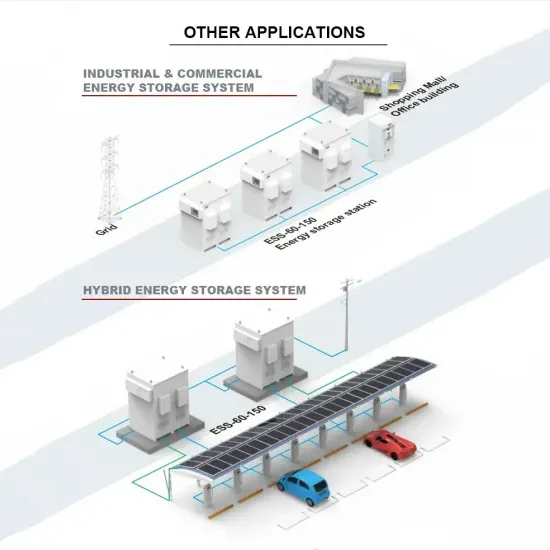

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

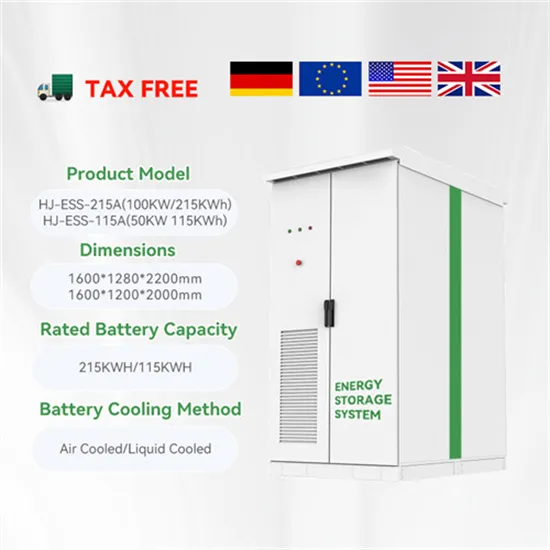

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.