Your Ultimate Lithium Batteries Buying Guide

Mar 13, 2025 · Most modern lithium batteries come with a Battery Management System (BMS) that protects against overcharging, overheating, and short circuits. However, physical damage

How to Charge a Lithium Battery Without a BMS | Redway Tech

Dec 7, 2023 · Charging lithium batteries without a Battery Management System (BMS) is possible but requires careful attention to safety and proper procedures. A BMS typically regulates

How Do I Choose a BMS for Lithium Batteries? | Redway Tech

Dec 14, 2023 · Choosing a Battery Management System (BMS) for lithium batteries involves considering factors such as voltage compatibility, current rating, cell balancing capabilities,

How To Choose A BMS For Lithium Batteries

Nov 27, 2023 · In the evolving world of battery technology, the debate over whether a Battery Management System (BMS) is necessary for lithium batteries remains prominent. This guide

The Role of BMS in Lithium Batteries: What You Need to

Feb 9, 2025 · Lithium batteries are widely used today, powering everything from smartphones to electric vehicles. A crucial component that ensures their safety and efficiency is the Battery

BMS for Lithium-Ion Batteries: The Essential Guide to Battery

Jul 22, 2025 · For lithium-ion batteries specifically, the BMS serves as a critical safety component that prevents dangerous conditions while optimizing battery performance. The BMS

Can I mix and match Victron Lithium Batteries (External BMS)

Jan 8, 2024 · Can I setup my system with an 100ah battery then add a 330ah in parallel next month? or should I always consistently buy the same capacity batteries? Also how long/after

Understanding Battery Management Systems (BMS) in Lithium Batteries

Simply put, every lithium battery must include a Battery Management System. At its core, a BMS acts as a traffic light for the battery —controlling whether the battery can charge or discharge

How does lithium battery BMS determine the

May 1, 2025 · This article will explore the functions, working principles, application areas, future development trends, and challenges of lithium battery BMS in

What Is a Lithium Battery Management System and How

Apr 23, 2025 · A Lithium Battery Management System (BMS) monitors voltage, temperature, and current to prevent overcharging, overheating, and short circuits. By balancing cell voltages and

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Apr 15, 2025 · Understanding the role of a BMS is necessary for anyone using lithium-ion batteries. In the next section, we will explore the various types of BMS systems available and

The Role of the BMS in Modern Lithium Batteries – Why It

Jul 23, 2025 · Modern lithium batteries are no longer simple storage units; they are intelligent energy systems designed to deliver safe, efficient, and lasting performance. At the heart of

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · What Does BMS Stand For? BMS stands for Battery Management System. It is an electronic control unit that monitors, manages, and protects rechargeable batteries, especially

The Importance and Advantages of Using a BMS for Lithium-Ion Battery

6 days ago · Lack of a properly integrated BMS for lithium ion battery puts customers at risk for shorter battery life, lower efficiency, and even more dangerous safety risks like fire or thermal

How to Choose Basic or Smart BMS for Lithium Applications?

When designing a lithium battery system, one of the most important choices is whether to use a basic or smart Battery Management System (BMS). While both serve the core purpose of

BMS capacity vs fuse size

Apr 19, 2024 · Cruisers & Sailing Forums > Engineering & Systems > Lithium Power Systems BMS capacity vs fuse size « Cheap charger for "manual" emergency charging? Please read

Best Trolling Motor Batteries For 24v [Updated On: August

1 day ago · For years, trolling motor batteries for 24V setups have often fallen short on durability and power stability, which is why I was excited to thoroughly test the latest options. After

3. System design and BMS selection guide

Mar 17, 2025 · This chapter describes things to consider on how the battery interacts with the BMS and how the BMS interacts with loads and chargers to keep the battery protected. This

6 FAQs about [Should I buy lithium batteries with BMS ]

Why should you use a BMS for a lithium-ion battery?

A properly designed BMS for lithium-ion batteries is not optional—it's essential for safe, reliable, and efficient operation. The technology protects valuable battery assets, ensures user safety, and maximizes performance throughout the battery's operational life.

What happens if you run a lithium battery without a BMS?

Operating a lithium battery without a BMS can expose it to risks that might compromise safety and efficiency: Overcharging and Deep Discharging: Without a BMS, cells in a battery can exceed their voltage thresholds during charging or can be depleted beyond safe levels, both of which can lead to battery damage or failure.

Are lithium-ion batteries safe to operate without BMS protection?

A: Operating lithium-ion batteries without proper BMS protection is extremely dangerous and not recommended. While basic protection circuits exist, they lack the comprehensive monitoring and management capabilities needed for safe operation.

What is a battery management system (BMS)?

The BMS is what prevents your battery cells from being drained or charged too much. Another important role of the BMS is to provide overcurrent protection to prevent fires. BMS modules are not expensive (compared to the rest of the battery pack) and they are relatively easy to install. So, there is really no reason to not use a BMS.

How accurate is a battery management system (BMS)?

Modern BMS systems achieve SOC accuracy within 3-5% under normal operating conditions. The BMS continuously evaluates battery degradation by monitoring capacity fade, internal resistance changes, and other aging indicators. This information helps predict remaining battery life and optimize charging strategies to slow degradation.

What happens if a BMS exceeds a battery voltage limit?

The BMS continuously monitors both individual cell voltages and total pack voltage to prevent operation outside safe parameters. If limits are exceeded for a length of time, not only is a potentially expensive battery pack compromised, but dangerous thermal runaway conditions could ensue.

Learn More

- BMS for lithium batteries

- Lithium iron phosphate battery 8 strings bms

- Bms lithium battery customization

- Lithium batteries and energy storage devices

- Chisinau good lithium battery bms

- Lithium battery to BMS

- Cylindrical lithium batteries are safer

- What are the types of cylindrical lithium batteries

- Differences between different types of cylindrical lithium batteries

Industrial & Commercial Energy Storage Market Growth

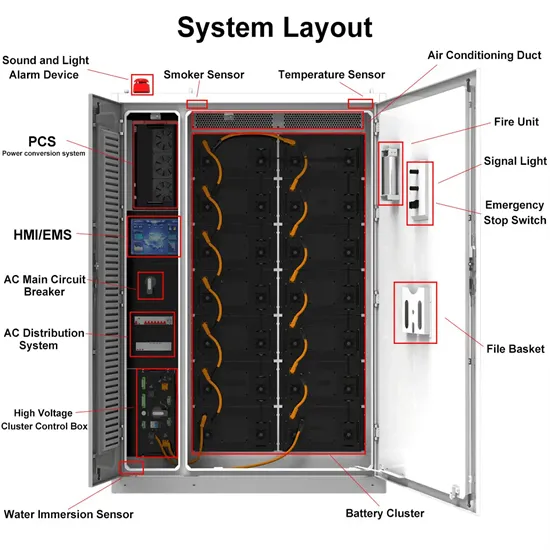

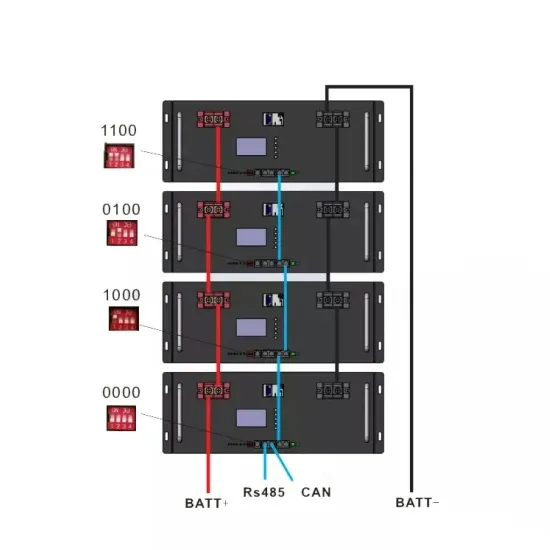

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

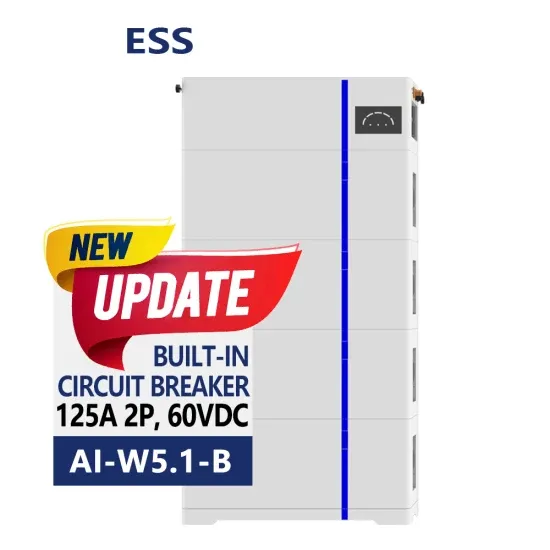

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.