Power Inverters: What Are They & How Do They

Dec 17, 2019 · Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for household and

Variable Frequency Inverter and Motor Matching Guide

Dec 21, 2023 · Common motor types include induction motors, permanent magnet synchronous motors, etc. Each type has its own unique operating principles and characteristics and

The difference between AC Inverter and DC Inverter | newji

Sep 25, 2024 · In today''s technologically advanced world, understanding the difference between AC inverter and DC inverter is essential, especially if you''re looking to optimize your energy

The Difference Between AC Motor Inverters and Motor

Aug 1, 2024 · Combined Use Cases Despite their functional and application differences, AC motor inverters and motor controllers are often used together in practical applications. The AC motor

Basics of inverter control and application to motor control

Jul 8, 2025 · The inverter allows altering the frequency and voltage of the power supplied to an electric motor, which governs the motor''s speed and torque. Inverter control is essentially the

A technical review of modern traction inverter systems used

Nov 1, 2023 · Single-stage power conversion, as indicated in Fig. 5 (a), employs high-voltage batteries and inverters, whereas double-stage power conversion uses relatively low-voltage

Inverter Motor Vs Traditional Motor: Which Is the Better

Apr 25, 2025 · The article compares inverter and traditional motors, highlighting energy efficiency, cost, and application suitability, guiding readers on selecting the right motor for industrial needs.

Comparison Between DC and AC Inverter Compressors for

Jan 11, 2025 · In this post, we will compare ten key aspects between DC inverter compressors and AC inverter compressors used in air conditioning systems. 1. Type of Motor AC inverter

Converting DC to AC: Basic Principles of Inverters

May 28, 2024 · This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC

What is the Main Difference Between AC and DC

3 days ago · Main Difference Between AC & DC Motor An electrical machine is a device that converts mechanical energy into electrical energy & vice versa. A

AC Motor Inverter Schematic: A Complete Tutorial On Circuit

Apr 14, 2025 · An AC motor inverter schematic converts direct current (DC) to alternating current (AC) to drive motors. It employs semiconductor switches, such as IGBTs, for efficient

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · In-phase shunt resistor based motor current sensing is done using AMC1300B isolated amplifier and DC link voltage, IGBT module temperature sensing using the AMC1311

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for

AC Motor Controller Explained | Motor Controllers

The AC motor receives power, which is converted by the AC motor controller into an adjustable frequency. This adjustable output allows the motor speed to be precisely controlled. Typically,

A Complete Guide to Inverters/Variable Frequency Drives

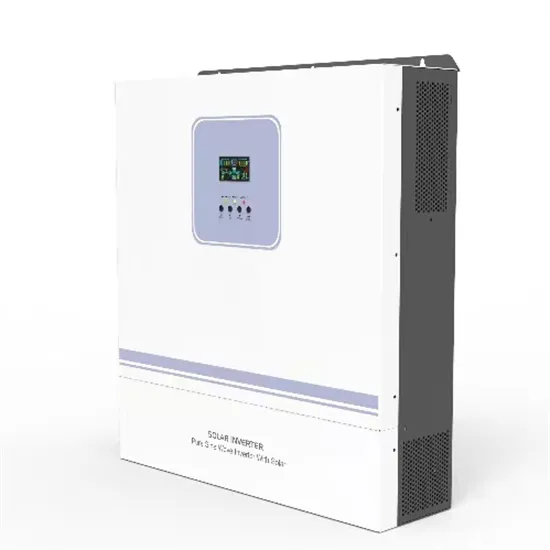

Sep 25, 2024 · There are different types of inverters designed to meet various needs, primarily categorized as AC inverters and DC inverters. AC inverters convert DC power, generally

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

What are Inverters and AC Input Brushless DC Motors?

4 days ago · A customer told me "I want to use an inverter or a brushless DC motor for speed control." I know about AC speed control motors, but I''m having trouble deciding which one is

Electric converters, motors and systems

High-voltage inverters convert direct current (DC) from batteries or generators to alternating current (AC) to power motors or other devices. Our inverters support a variety of applications,

What Is an Inverter in an Electric Vehicle?

Aug 9, 2023 · An inverter is a device that converts direct current (DC), which is supplied from a battery, into alternating current (AC). A motor in an electric vehicle runs on this alternating

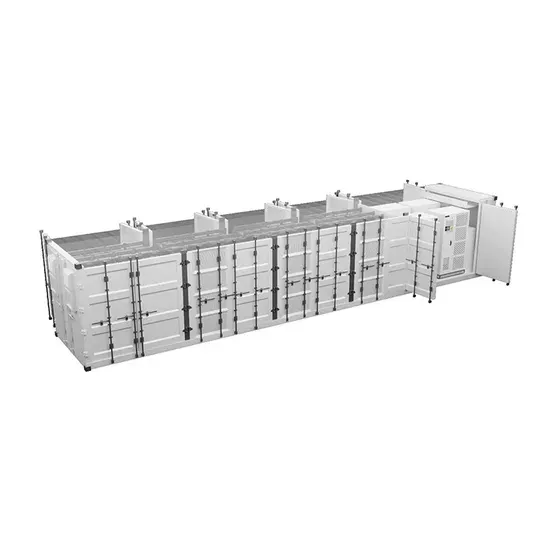

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

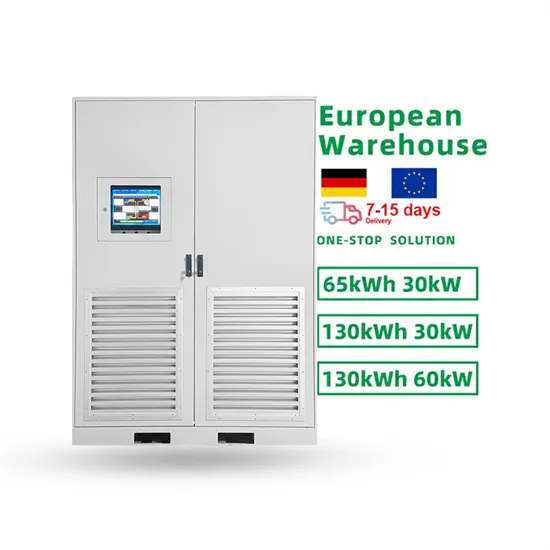

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.