Industrial Electronics Basics: What is an Inverter

Sep 26, 2022 · It''s recommended to match the motor''s speed or torque to the required specifications since this increases the system''s overall efficiency,

Inverter Drives Explained: The Future of Efficient Motor Control

Jul 17, 2024 · In conclusion, inverter drives are a versatile and efficient solution for controlling the speed and torque of electric motors. By converting DC voltage into AC voltage and providing

Electric Motor Inverter Explained

Jun 23, 2025 · It converts the battery''s direct current (DC) into the alternating current (AC) needed by the motor, controlling torque, speed, and regenerative braking. This core function ties

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · An inverter drive, or Variable Frequency Drive (VFD), converts AC mains into DC using rectification. Capacitors and sometimes a DC choke smooth the DC current. The

Multi-Level Inverter Fed Induction Motor Drive

Mar 8, 2022 · 1 Faculty, 2, 3, 4,5 Student, Dept. of Electrical and Electronics Engineering, GNDEC College, Karnataka, India Abstract –The multi-level pwm is asophistorical technique for

Reversible High-Power Three-Phase DC/AC Inverter Family Motor Drive

With BrightLoop''s hallmark versatility and modularity, our inverters deliver up to 500 kW of power with an exceptional power density exceeding 50 kW/kg. Embedding cutting-edge top-side

What is an Inverter Drive and what are its features?

Dec 21, 2023 · An inverter drive, also known as a variable frequency drive (VFD) or adjustable frequency drive (AFD), Darwin Motion Micro Drive- Matrix 900,

The difference between an inverter and a motor controller

Feb 28, 2025 · The role of the motor inverter The motor inverter is an electric energy conversion device that converts DC power into AC power to control the speed and torque of the AC motor.

What are Inverters and AC Input Brushless DC Motors?

5 days ago · A customer told me "I want to use an inverter or a brushless DC motor for speed control." I know about AC speed control motors, but I''m having trouble deciding which one is

Inverter Drives | Variable Frequency Drives

An inverter drive is a variable speed drive that allows users to adjust the speed or output of an electric motor. It is also called an adjustable speed drive, adjustable frequency drive,

What are Inverters and AC Input Brushless DC Motors?

5 days ago · Inverters are used in combination with a three-phase 200 VAC motors to control the rotation speed by changing the power supply frequency. All you need to connect is a power

Electric converters, motors and systems

High-voltage inverters convert direct current (DC) from batteries or generators to alternating current (AC) to power motors or other devices. Our inverters support a variety of applications,

Learn More

- Installation of inverter DC motor

- Inverter and DC Motor

- What is the DC current data of the Sunshine 50k inverter

- Guyana DC Power Inverter Price

- DC module bidirectional inverter

- DC screen inverter 5kva

- Single-phase inverter DC component suppression

- 192v DC Inverter

- Three-phase inverter DC side voltage

Industrial & Commercial Energy Storage Market Growth

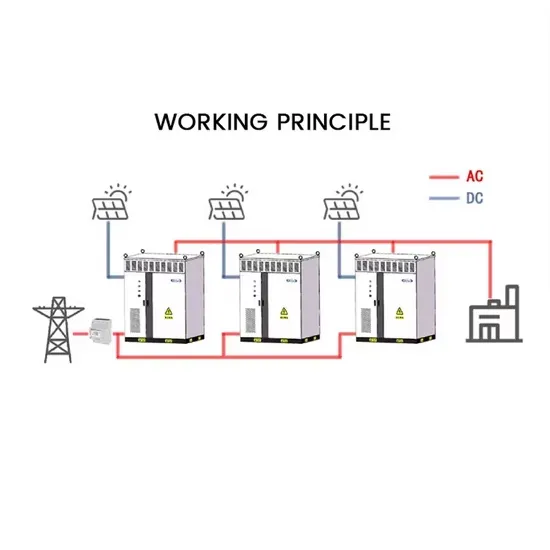

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

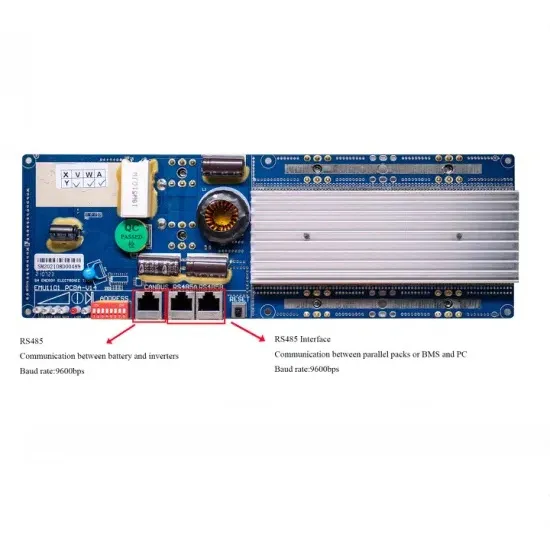

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.