Connect your inverter to the battery with ease

An inverter is an essential component in any off-grid or backup power system. It converts direct current (DC) electricity from a battery bank into alternating current (AC) electricity that can be

How to Connect the Battery With Your Appliance – LiTime-US

Learn how to connect your lithium battery to inverters and appliances the right way in this step-by-step tutorial. Safety is the top priority as our expert guides you through the full process. Watch

Can A Battery Run An AC Motor? Direct Connections, Inverters

Apr 25, 2025 · Yes, a battery can run an AC motor using an inverter. The inverter changes direct current (DC) from the battery into alternating current (AC). This AC power is necessary for the

Connecting Your Battery and Inverter for Optimal Performance

Jan 14, 2024 · Linking your inverter and battery requires careful attention to detail. First, you''ll need to ensure that the voltage and capacity of your battery are compatible with your inverter.

Do I Need A Fuse Between Battery And Inverter? Key

Feb 15, 2025 · It is crucial to install a fuse between the battery and inverter. A Mega fuse or ANL fuse is recommended because they manage high short-circuit currents well.

Can I connect car alternator directly to the invertor

Apr 19, 2017 · I''d be more tempted to connect the invertor to a battery and try and use the wind turbine/alternator to charge the battery. This way you are not relying on the alternator to

Inverter connection diagram. Install Inverter and

Nov 12, 2024 · Today we are going to learn How to Install an Inverter and Battery at Home, Inverter connection diagram. Load shedding in our country is very

Powering An AC Motor Of Battery: Can You Run It Without An Inverter

Apr 15, 2025 · An inverter serves this purpose, allowing batteries to power AC motors by changing the direct current into alternating current. Some specialized motors, like certain types

Run An AC Motor With Battery: DIY Inverter-Free Solutions

May 30, 2025 · To run an AC motor with a battery, use an inverter or motor controller. These devices convert the battery''s DC voltage into the AC voltage needed by the motor. They also

How to Connect an Inverter to a Battery: Step-by

Mar 11, 2025 · Step-by-Step Guide to Connecting Inverter to Battery. Identify the Battery Terminals: Locate the positive (+) and negative (-) terminals on the

Connect an Inverter to a Battery: DIY Guide & Integrated

Learn how to connect an inverter to a battery safely and effectively. Explore DIY options, understand essential components, and discover the benefits of integrated inverter-battery

Inverter Battery Connection: Essential Tips For Safe And

Nov 16, 2024 · Connecting an inverter to a battery involves more than just attaching wires. It''s a process that requires care, precision, and adherence to safety protocols. Turn off both the

Battery Connected Multi-level Inverter Fed PMSM for Electric

May 18, 2023 · This work outlines Battery connected Multilevel inverter fed PMSM Electric Vehicle topology. Permanent Magnet Synchronous Motor (PMSM) has many advantages like high

Can I Connect an Inverter Directly to a Battery? –

May 30, 2023 · Connecting an inverter to a battery is a critical step in establishing a reliable and efficient power supply system. By carefully assessing power

How to Safely Connect a Battery to an Inverter: A

Apr 13, 2025 · Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

6 FAQs about [Battery connected to inverter and motor]

How do you connect an inverter to a battery?

Connect the positive cable first. Attach the red cable to the positive terminal on both the inverter and the battery. Attach the negative cable. Connect the black cable to the negative terminal, ensuring secure attachment to prevent loose connections. Always use insulated tools to avoid unintentional contact with live wires.

What are inverter battery connections?

Inverter battery connections form the backbone of reliable power systems, ensuring efficient operation and safety. By following best practices and understanding the nuances of these connections, you can enhance system performance and longevity.

Why do you need a battery connection for an inverter?

The DC comes from the batteries which are used to power the inverter, and this inverter transforms the power into AC usable by bulbs, fans, and other small electrical devices. You must go through battery connection for inverter while considering the risks of electrical shocks, damage to devices, so that potential fire risks are avoided.

Should you connect multiple batteries to an inverter?

For increased power needs, connecting multiple batteries to an inverter is often necessary. Here’s how to do it right. When connecting two batteries, they are typically set up in parallel (positive to positive, negative to negative) to increase capacity without changing voltage.

How do you connect an inverter to a battery without sparking?

To connect battery terminal wires without sparking, the positive wire is connected to its terminal first and negative wire in the last. Double check all connections then turn the inverter on. 3. Which wire is used to connect an inverter and a battery?

Do inverters and batteries need to match?

The inverter and batteries must match in terms of voltage, capacity, and power output. If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment.

Learn More

- Base station battery connected to inverter

- Inverter connected to battery and fan

- Can the UPS inverter be connected to the power supply to charge the battery

- Can the 12v lithium battery in Antananarivo be connected to an inverter

- What battery should be connected to the photovoltaic panel inverter

- RV lithium battery connected to inverter

- Can a 60 volt inverter be connected to a 72v battery

- Nine e series battery connected to inverter

- Power battery connected to inverter

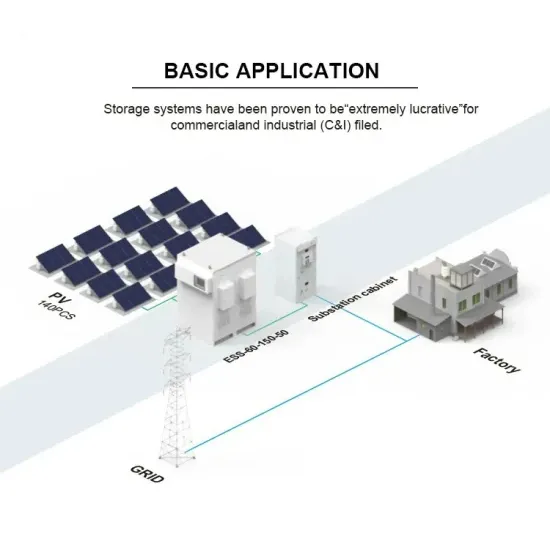

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.